Driving device for leaf of door or window

A driving device and leaf-leaf technology, applied in door/window fittings, wing leaf parts, switches with brakes, etc., can solve the problems of door closers, such as possible solutions, durability and operating comfort.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

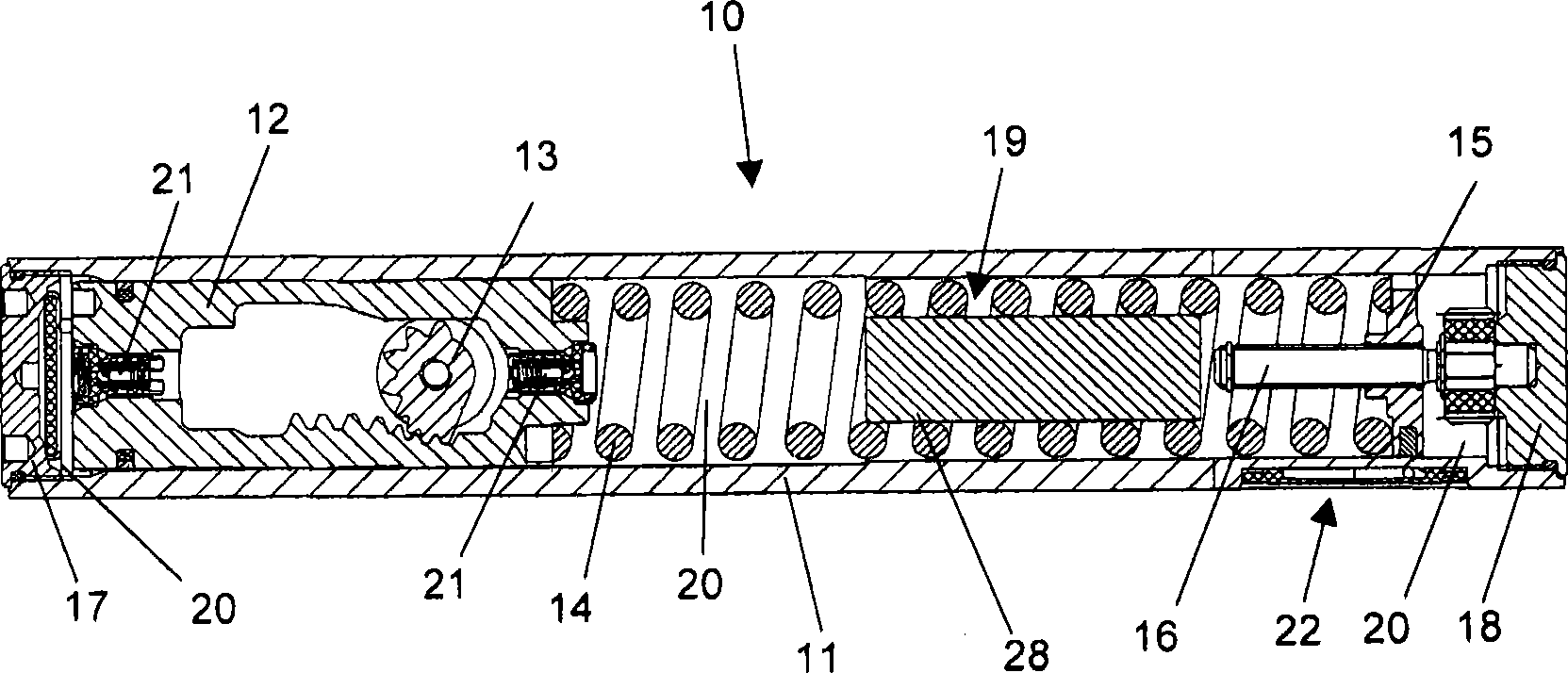

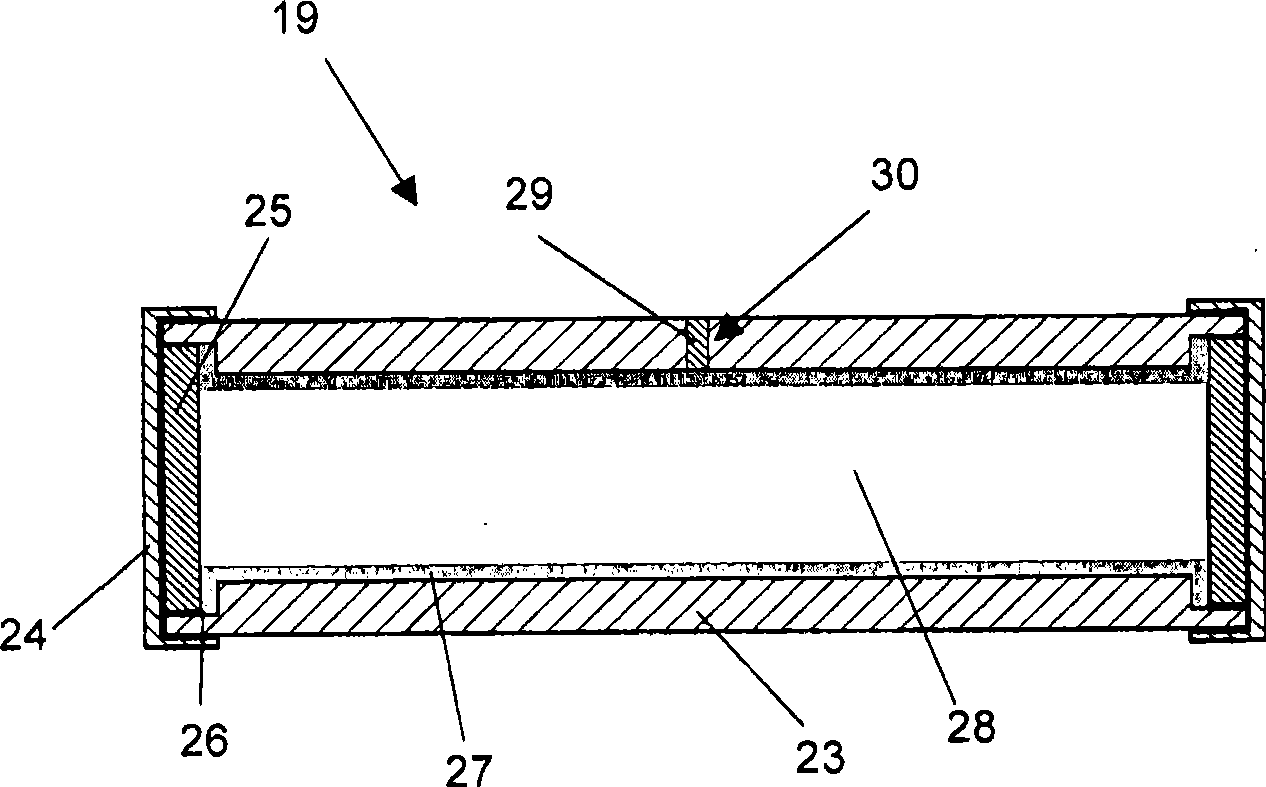

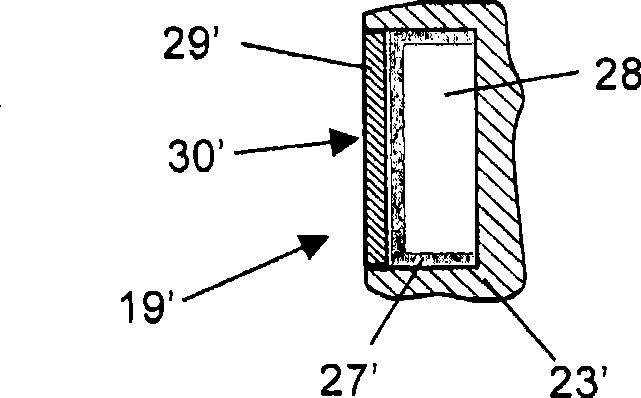

[0022] exist figure 1 A horizontal section through a drive device 10 designed as a door closer can be seen in FIG. The drive device 10 comprises: a housing 11 configured as a cylindrical tube as the main component; a working piston 12 guided linearly displaceably in a bore of the housing 11 and engaging a transmission gear 13 in its toothed rack a helical compression spring 14, which is supported axially between a ring end face of the working piston 12 and an opposite ring end face of a spring disk 15, wherein the spring disk 15 can be moved axially relative to the working piston 12 is guided along an adjusting screw 16; a housing cover 17 for closing on the left end of the housing 11 and a housing cover 18 for closing on its right end and a cylindrical compensating container 19 , which is arranged in the hollow cross-section of the helical compression spring 14 . The spring force is adjustable, since the spring disk 15 is adjustable along the adjusting screw 16 from the out...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com