Setting and unsealing mechanism for underground sealing short section

A sub-joint and unsealing technology, which is applied in the directions of sealing/isolation, wellbore/well components, earthwork drilling and production, etc., can solve the problems of large unsealing force and difficult reset of the hydraulically driven sealing sub-joint, and achieves simple action, Easy to operate and low unsealing force

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

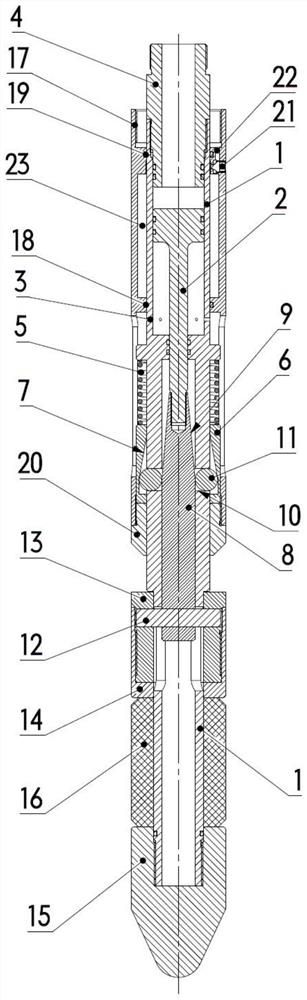

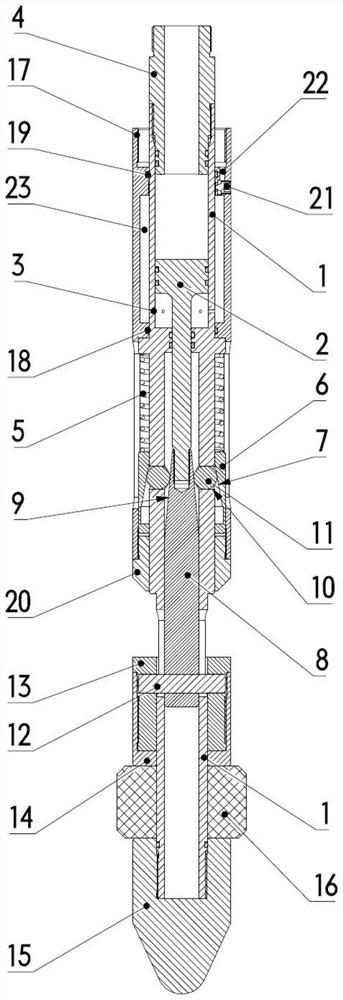

[0016] The invention will be described in detail below in conjunction with the accompanying drawings.

[0017] see figure 1 , figure 2 , a setting and unsealing mechanism that can be used for downhole sealing pup joints, including a piston barrel 1, the upper end of the piston barrel 1 is threadedly connected to the upper joint 4, and the piston end of the piston rod 2 is arranged in the piston barrel 1 and below the upper joint 4 , the connecting end of the piston rod 2 is threadedly connected with the top of the push rod 8, the outer circumference of the top of the push rod 8 is provided with a first small-angle conical surface 9, the wall of the piston cylinder 1 is provided with a pressure guide hole 3, and the piston rod 2 piston end The lower space communicates with the external environment; the outer side of the piston cylinder 1 is sequentially covered with a sleeve 17, a spring 5, an inner cone sleeve 6, a spiral ring 20, a thrust ring 13, a pressure sleeve 14, a ru...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com