Side-loading compression garbage truck

A garbage truck and compression type technology, which is applied in the field of side-mounted compression garbage trucks, can solve the problems of small amount of garbage loaded, small compression ratio, large wear, etc. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The present invention will be further described below in conjunction with accompanying drawing.

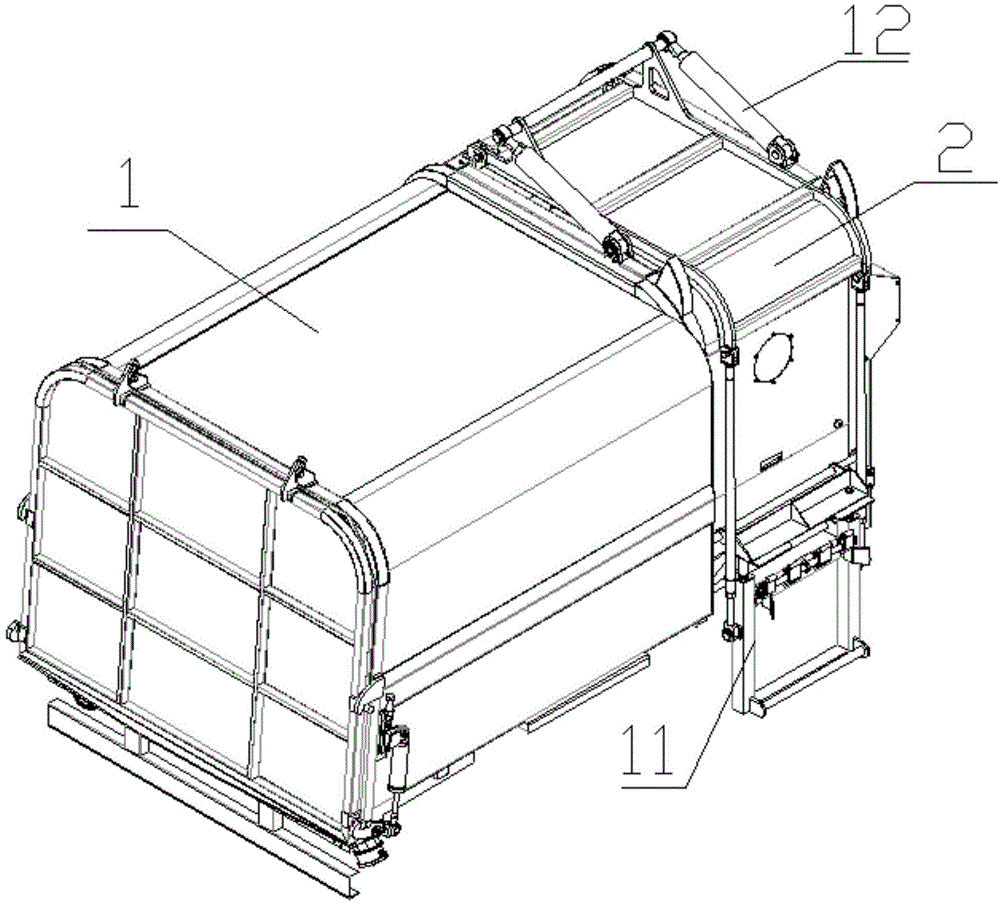

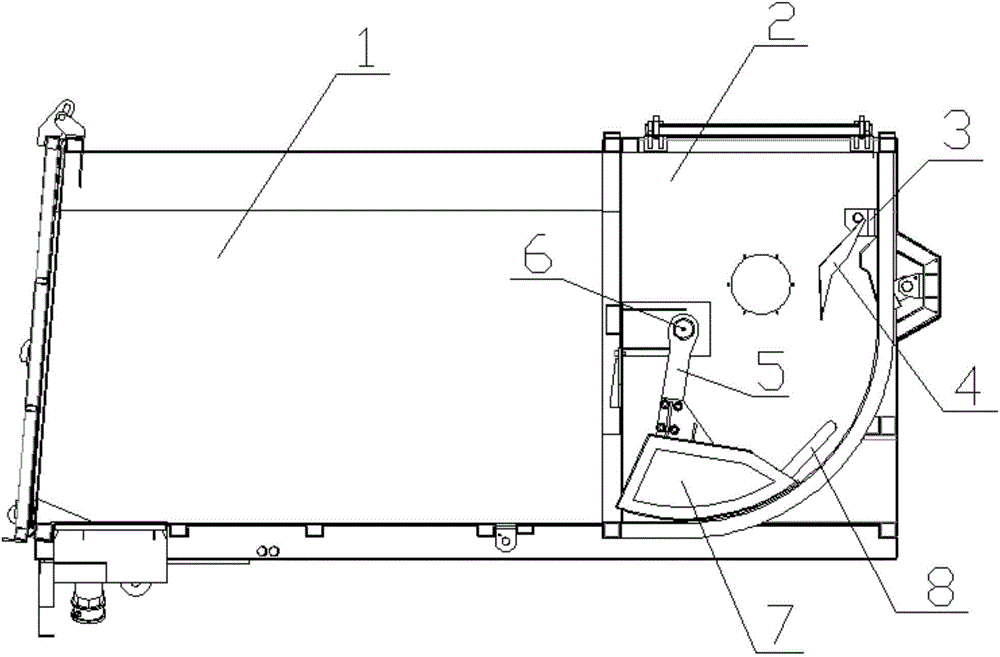

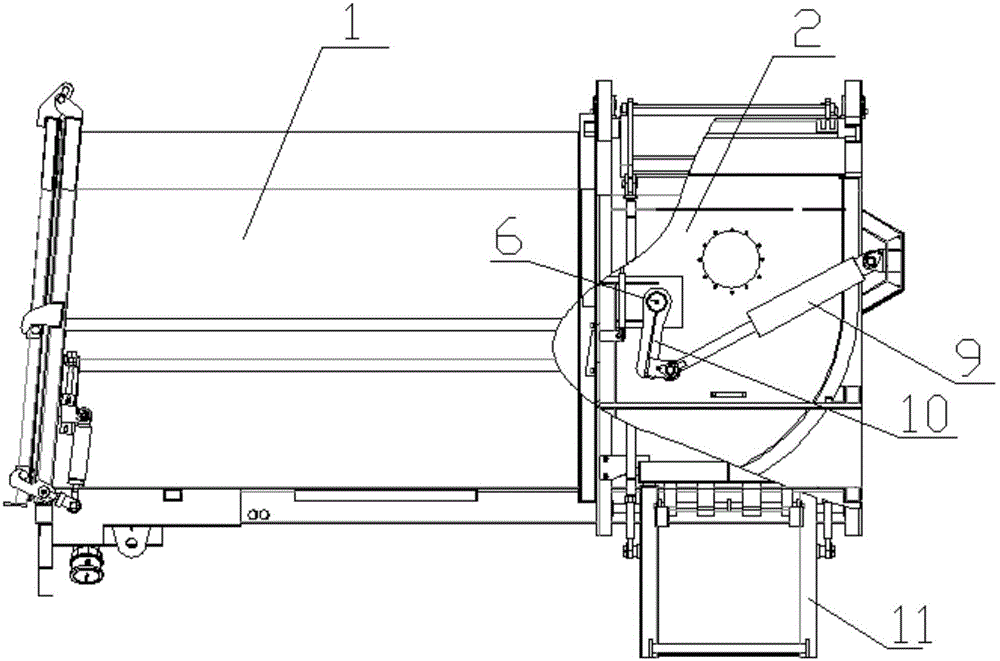

[0023] like figure 1 , figure 2 , image 3 , Figure 5 and Image 6 As shown, the present invention includes a storage bin 1, a compression bin 2, a lifting and turning mechanism and a rotary compression device. The compression bin 2 is arranged at one end of the storage bin 1 and connected through a compression port provided on the storage bin 1 to lift and turn over the barrel. The mechanism is installed on the side of the compression chamber 2; the rotary compression device is placed in the compression chamber 2, and the rotary compression device includes a rotary pusher 7 and a swing rod 5, one end of the swing rod 5 is fixed on the upper part of the rotary pusher 7, and the other end It is connected with the rotating shaft 6 arranged on the side wall of the compression chamber 2, so that the rotary push head 7 closes the compression port when it is closest to the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com