Full-automatic numerical control woodworking, enchasing and forming machine

A fully automatic, forming machine technology, applied in the direction of processing models, carvings, decorative arts, etc., can solve the problems affecting the processing accuracy of products, low processing accuracy, large vibration, etc., to increase the flexibility of use, high processing accuracy, and stable work. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

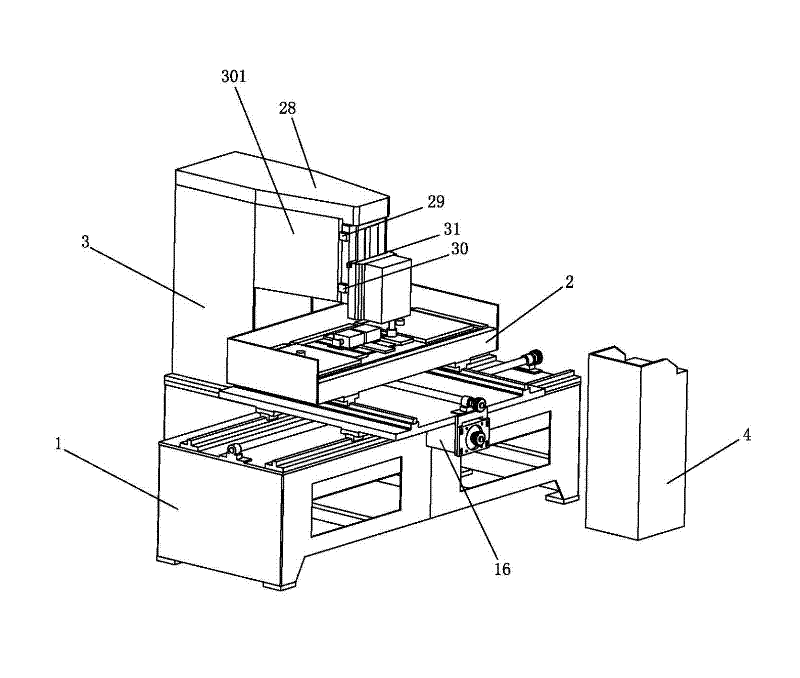

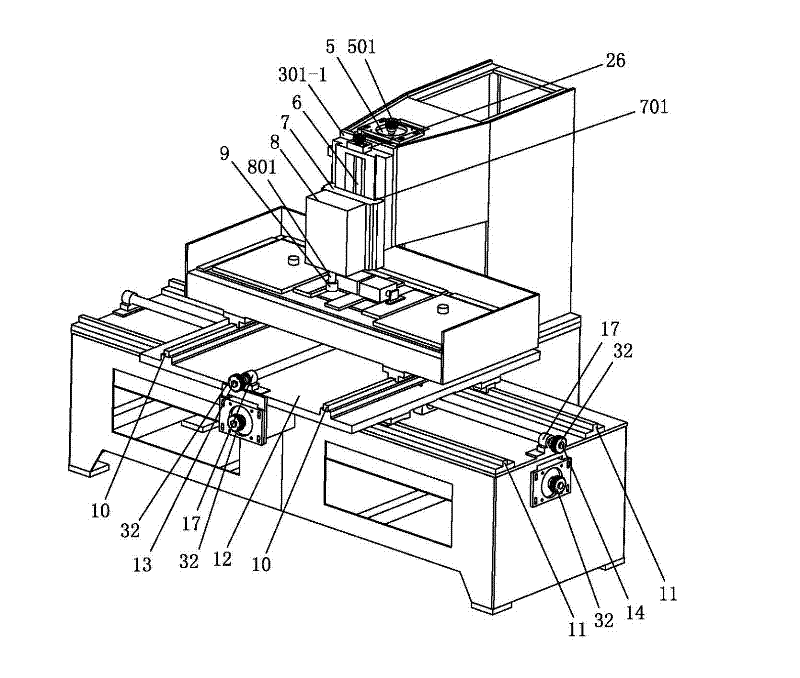

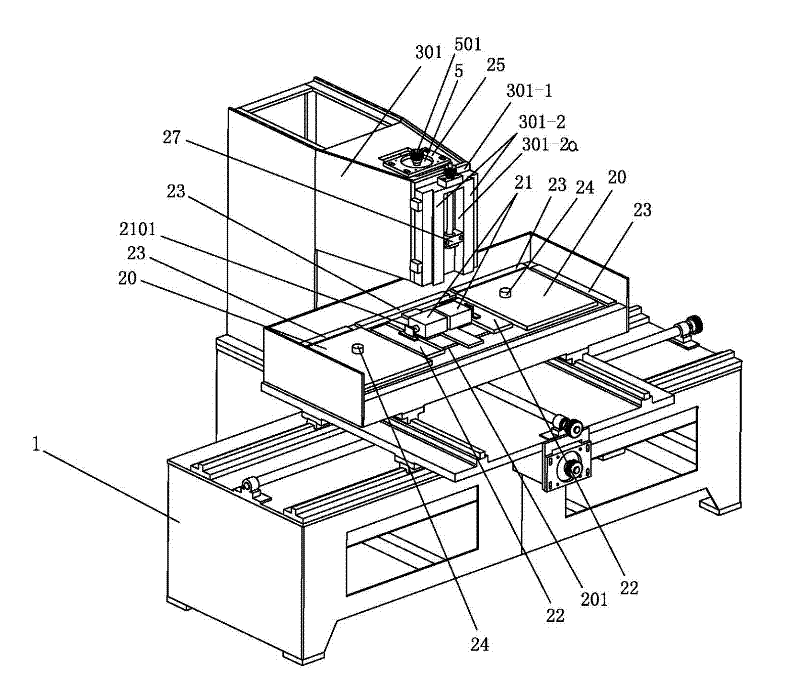

[0027] Such as Figure 1 to Figure 5 As shown in the figure, a fully automatic CNC woodworking engraving machine, the body 1 is provided with a workbench 2, a spindle fixing seat 3 and a numerical control device 4.

[0028] The main shaft fixing seat 3 is fixedly extended with a cross arm box 301 suspended above the workbench 2 of the fuselage 1, and the main shaft lifting servo motor 5 is fixed inside the cross arm box 301, and the output shaft 501 of the main shaft lifting servo motor 5 Extend the top of the cross arm box 301 and connect with the lifting screw 6 fixed on the front end 301-1 of the cross arm box 301 through a belt, and the lifting screw 6 on the front end 301-1 of the cross arm box 301 is also sleeved There is an elevating carriage 7 sliding up and down along the elevating screw mandrel 6, and the elevating carriage 7 is fixed with a ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com