Mixed mode stone embossed preparing technique and adoptive sculpturing machine

A production process and composite technology, applied in the field of engraving machines, can solve the problems of high labor intensity, difficult mass production, low production efficiency, etc. The effect of improving production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

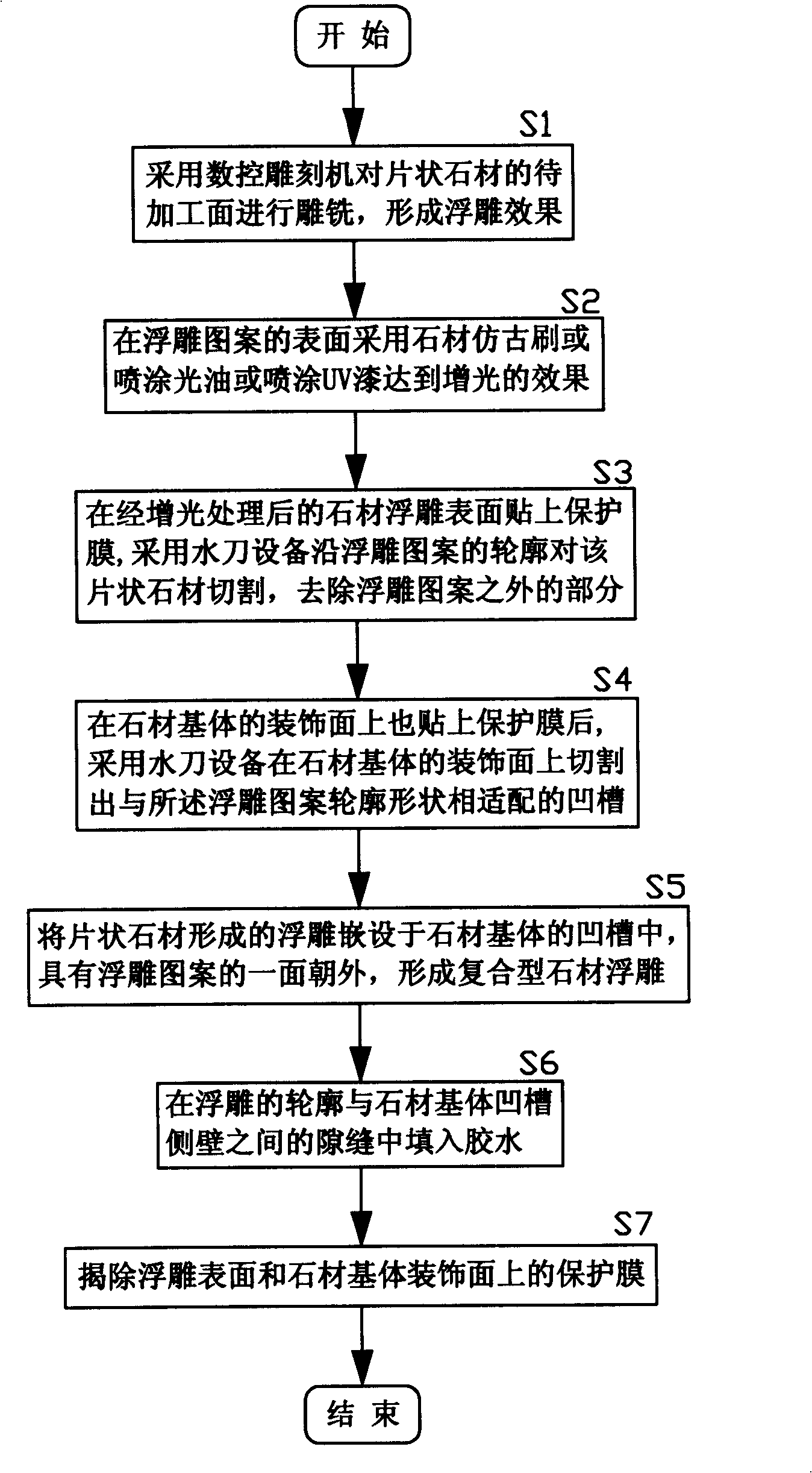

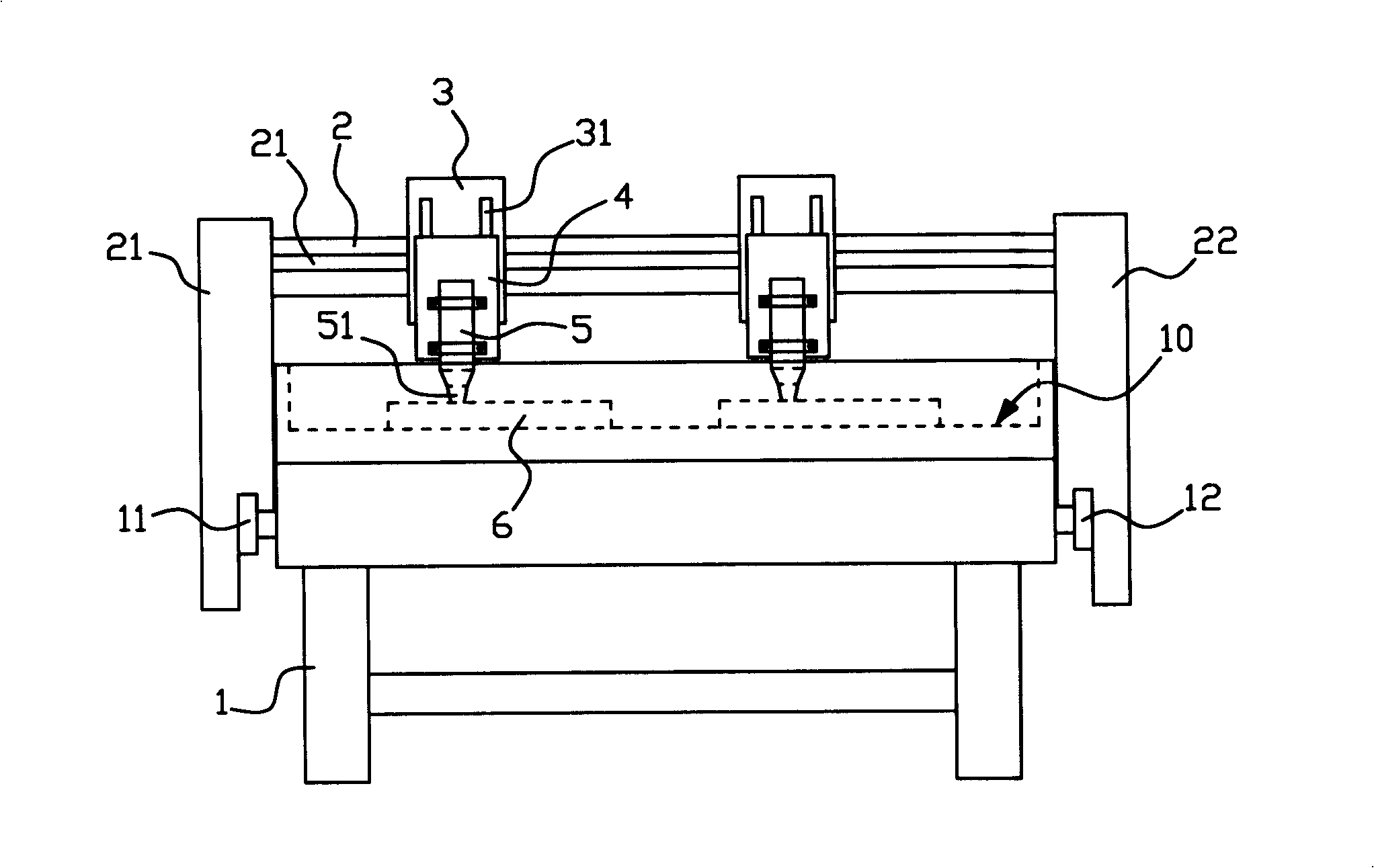

[0016] The essence of the present invention is to first use a numerical control engraving machine to engrave and mill the surface of the flake stone to be processed to form a relief effect, then cut out the contour of the relief and the groove on the substrate with a waterjet device, and finally embed the relief into the groove In this way, a composite stone relief is formed. Refer below figure 1 The process flow of the specific embodiment of the present invention is described.

[0017] First, use a CNC engraving machine to engrave and mill the surface of the flake stone to be processed to form a relief effect (step S1), and use stone antique brushes or spray varnish or spray UV paint on the surface of the relief pattern to achieve a gloss enhancement effect (step S1) S2).

[0018] Secondly, a protective film is pasted on the surface of the stone relief after the light-enhancing treatment, and the sheet stone is cut along the outline of the relief pattern using a water jet device...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com