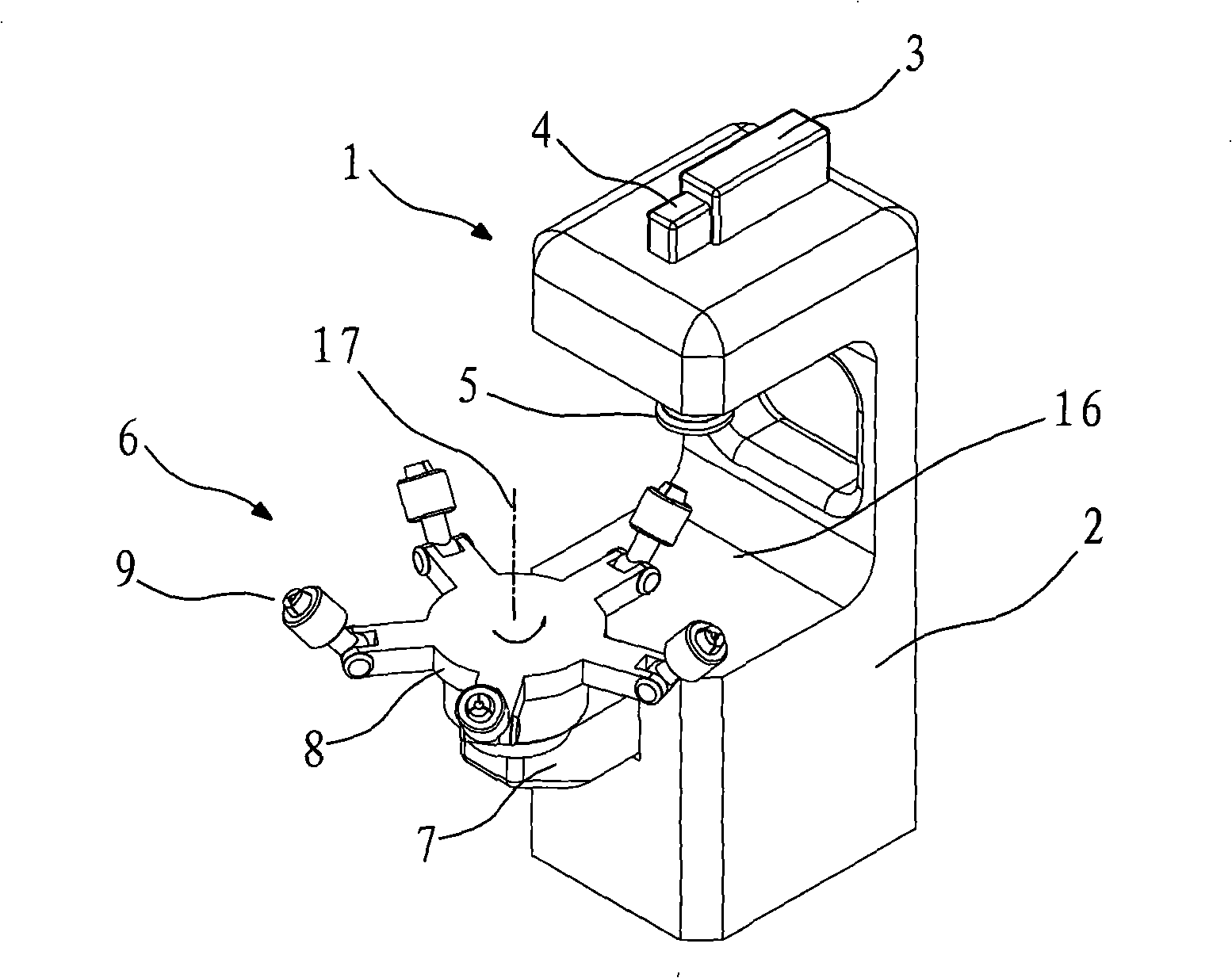

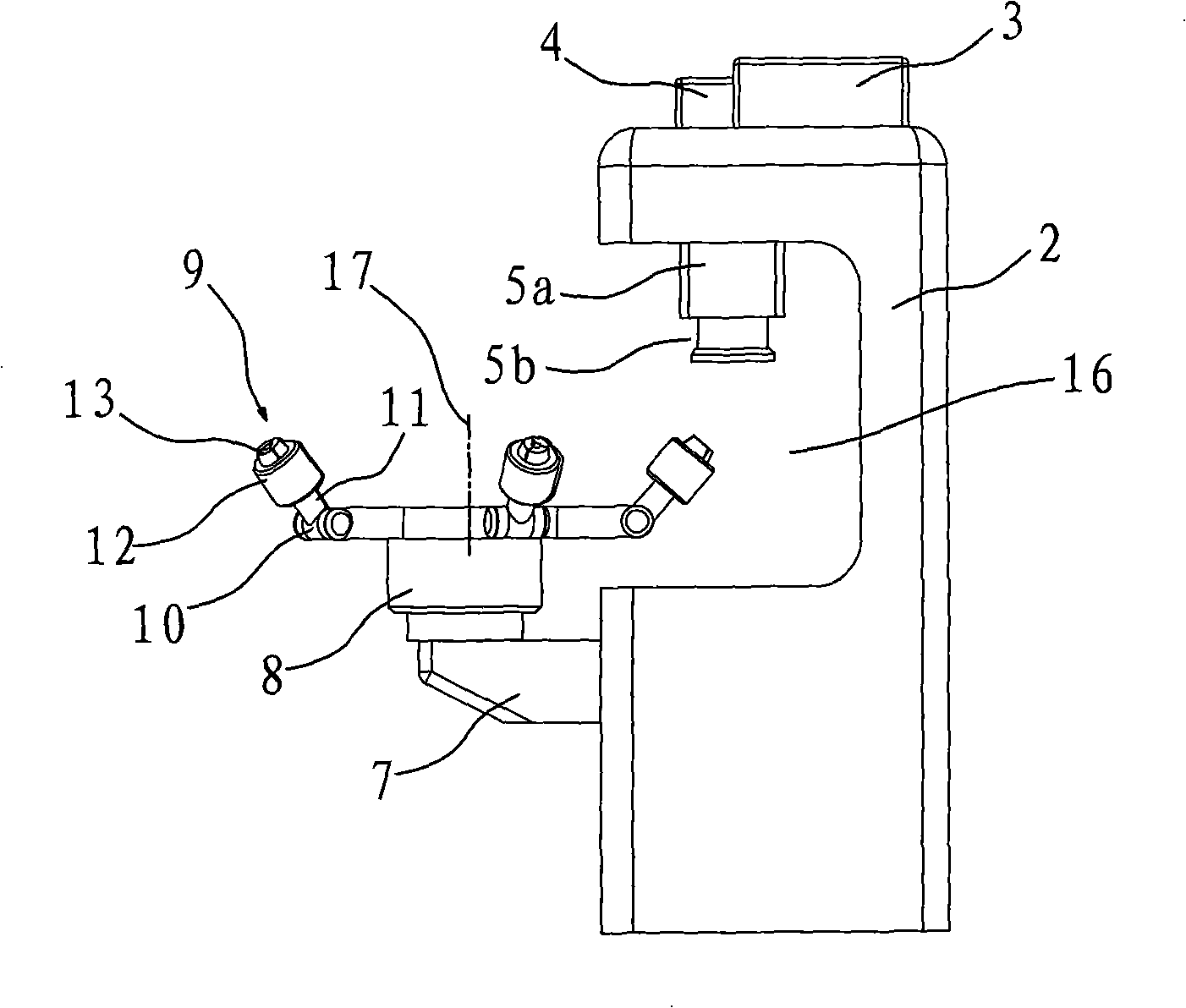

Multi-loading-unit rotary exchange type laser engraving device

A laser engraving machine and switching technology, which is applied in the field of laser engraving machines, can solve problems such as difficulty in improving work efficiency, and achieve the effect of improving overall efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 3

[0055] Embodiment 3 is similar to embodiment 2, the difference is only by Figure 7The laser 3 shown is placed separately from the laser operation device 1, and a protective tube 15 is added to the optical path 4 for safe operation, so that the laser can run shielded in the protective tube 15, which is necessary for the safety protection of high-power laser operations of.

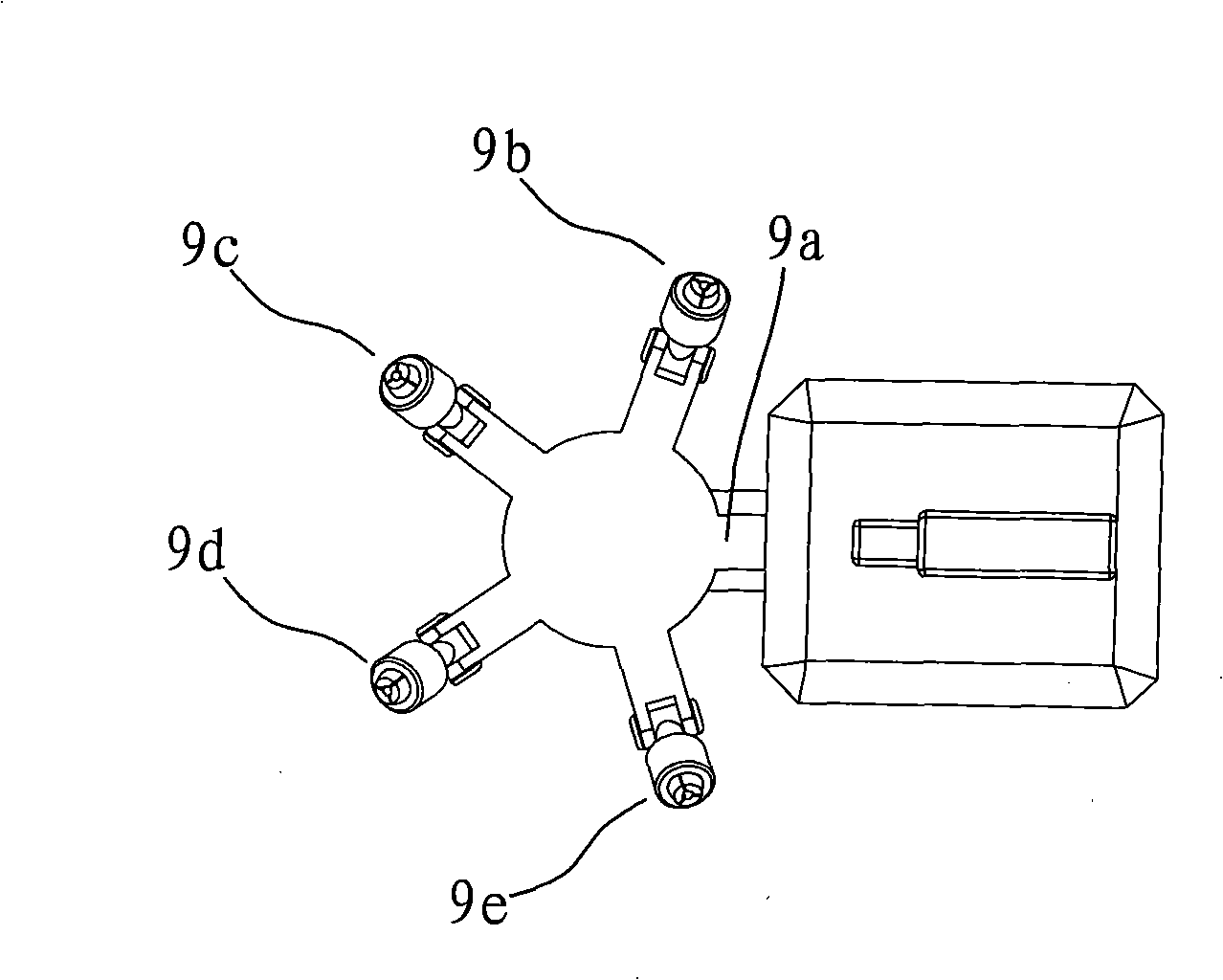

[0056] To sum up the above embodiments, the focus of the design of the present invention is to replace the existing single-station operation structure with the rotary exchange load device with multiple load units, that is, to replace the intermittent intermittent operation mode with the continuous exchange operation mode, so that Especially in the laser operation, the multi-station operations related to the front and rear processes can be carried out at the same time, especially the pre-loading operation or upstream preparation operation of the laser operation, and the downstream related operations or unloa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com