Profile modeling laser engraving process method and laser carving machine thereof

A laser engraving machine, laser engraving technology, applied in the direction of processing models, laser welding equipment, metal processing equipment, etc., can solve the problem of not being able to adjust the focus of special-shaped materials in real time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0031] Referring to Fig. 9, a profiling laser engraving processing method comprises the following steps:

[0032] (1) Place the workpiece to be processed on the laser engraving machine;

[0033] (2) Control the CCD laser displacement sensor of the laser engraving machine to detect the distance between the laser head and the workpiece, obtain the focus measurement data, and send it to the special system for the laser engraving machine;

[0034] (3) After the special system for laser engraving machine obtains the focal measurement data of the entire workpiece, it sends the data to the computer;

[0035] (4), the computer generates a three-dimensional topographic map of the workpiece based on the data, and under the condition of ensuring that the focus of the laser falls on the surface of the workpiece, calculates the position of the laser head of each stroke according to the processing process points, and generates X-axis, Y The control signal of the driving motor of the axis f...

Embodiment 2

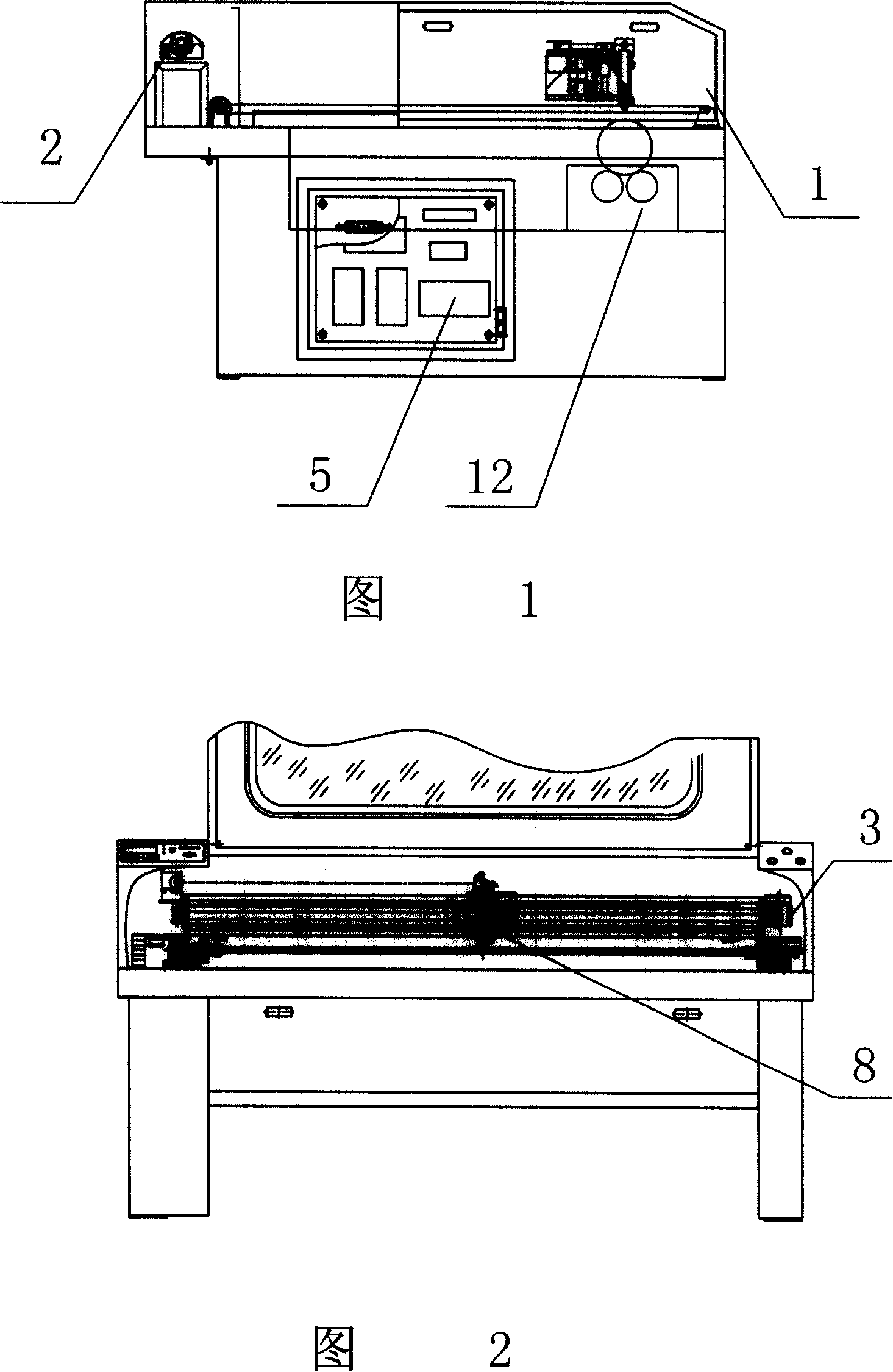

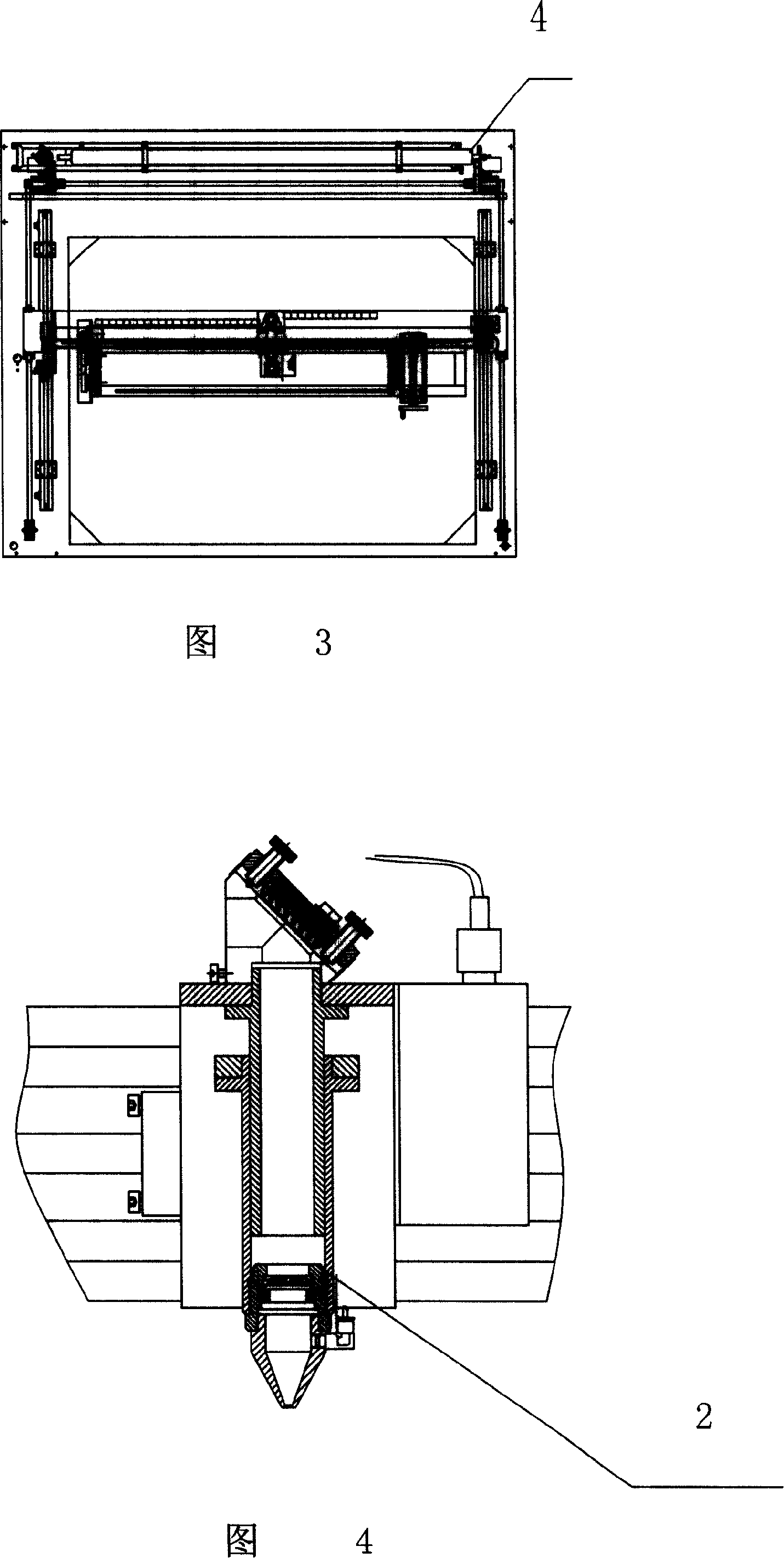

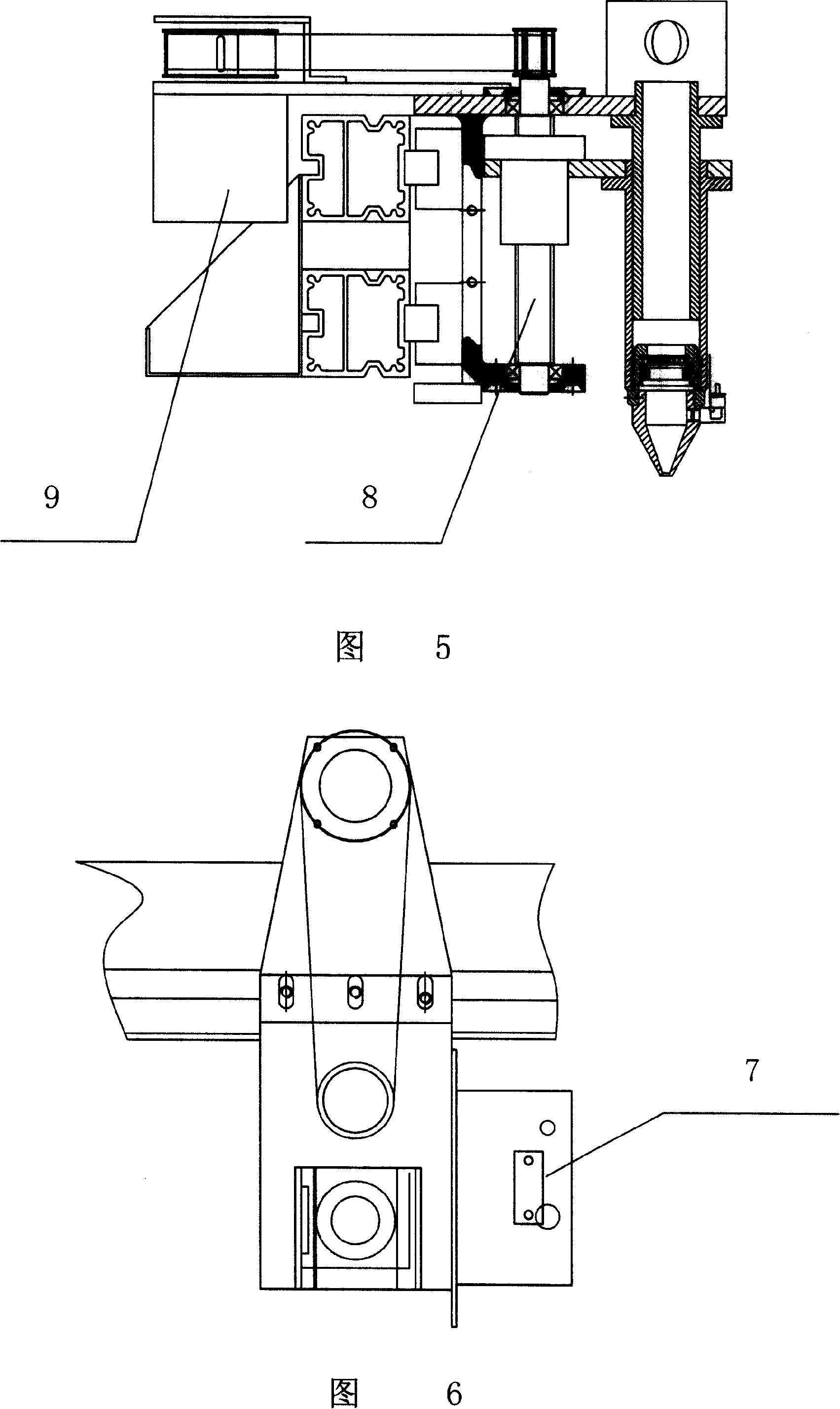

[0039] Referring to Figures 1 to 9, a laser engraving machine includes a frame 1, a laser head 2, X-axis and Y-axis flight mechanisms 3 and 4 connected to the laser head 2, and a host controller 5 for controlling profiling engraving , the X-axis, Y-axis flying mechanism 3,4 are installed on the frame 1, and the upper controller 5 includes engraving for controlling the travel of the X-axis and Y-axis flying mechanism and setting the trajectory of the laser head Processing module 6, described engraving processing module 6 is connected X-axis, Y-axis flying mechanism 3,4, and described laser engraving machine also comprises Z-axis driving mechanism perpendicular to workpiece surface, CCD laser displacement sensor 7, described Z The shaft drive mechanism includes a Z-axis transmission mechanism 8 and a control motor 9. The Z-axis transmission mechanism 8 is connected to the laser head 2, and the Z-axis transmission mechanism 8 is fixedly connected with the CCD laser displacement se...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com