Method and system for clearing blockage of ore chute

A technology for mine chute and chute, which is applied in the field of dredging blockage of mine chute, to avoid accidental personal injury accidents, improve the strength of support structure, and avoid potential safety hazards

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

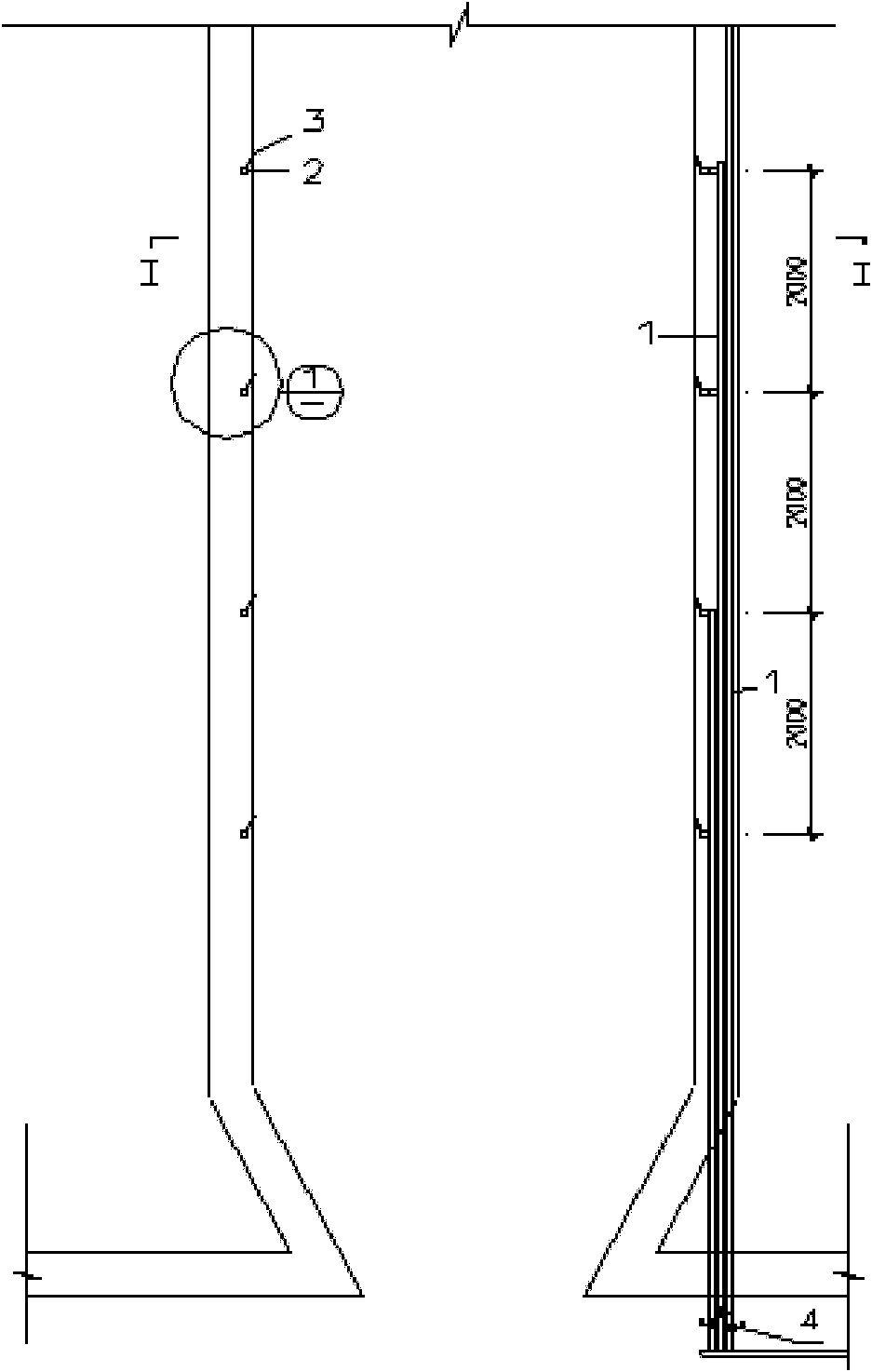

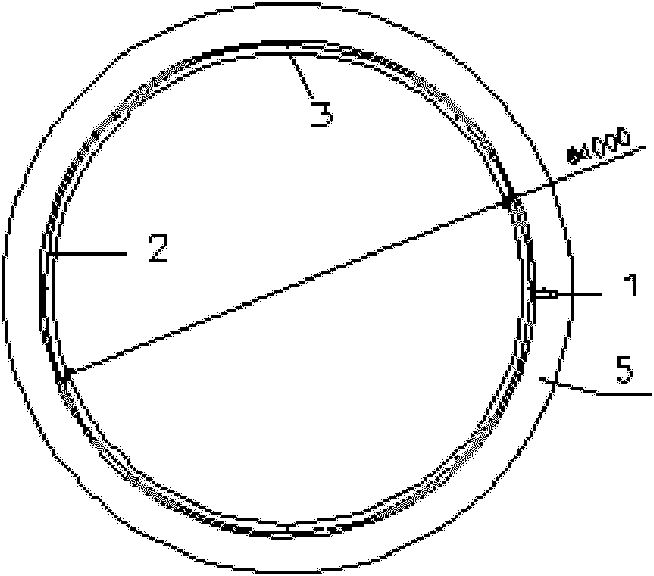

[0036] Be the chute of 4 meters with diameter as example, the implementation of the present utility model is carried out according to the following steps:

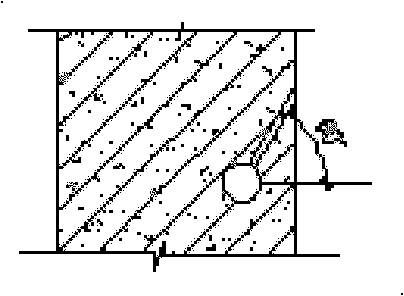

[0037] The first step is to implement concrete reinforcement on the chute, according to the attached figure 1 The arrangement shown is to embed a steel pipe 1 with a diameter of 60mm and an annular steel pipe 2 with a diameter of 40mm. Each steel pipe 1 is connected with two annular steel pipes 2. ) is 2 m. Eight steel pipes 3 with a diameter of 15mm are welded on the annular steel pipe 2, and the steel pipes 3 are evenly arranged on the annular steel pipe 2, and the upper and lower layers of steel pipes 3 are arranged in a staggered manner. When pouring concrete on the chute wall, it is necessary to prevent the steel pipe 3 from being blocked;

[0038] Step 2 After the chute support is completed, when installing the mine air supply system, connect the steel pipe 1 at the bottom of the chute to the mine air supply pipel...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com