Self-movable foot end of belt conveyer

A technology of belt conveyor and self-moving tail, which is applied to conveyors, conveyor objects, underground transportation, etc., and can solve the problems of large handling, complex structure, and high assembly requirements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

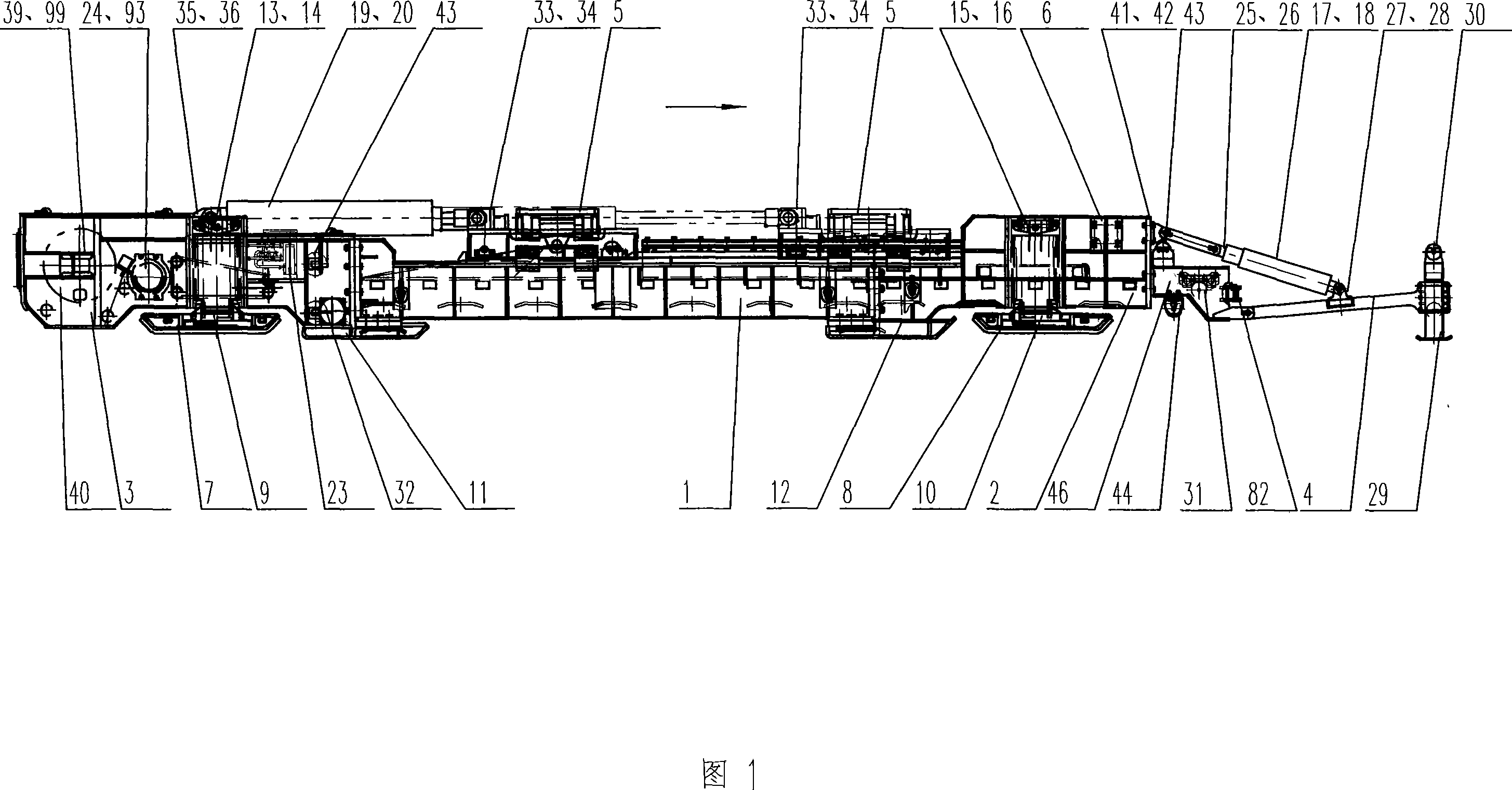

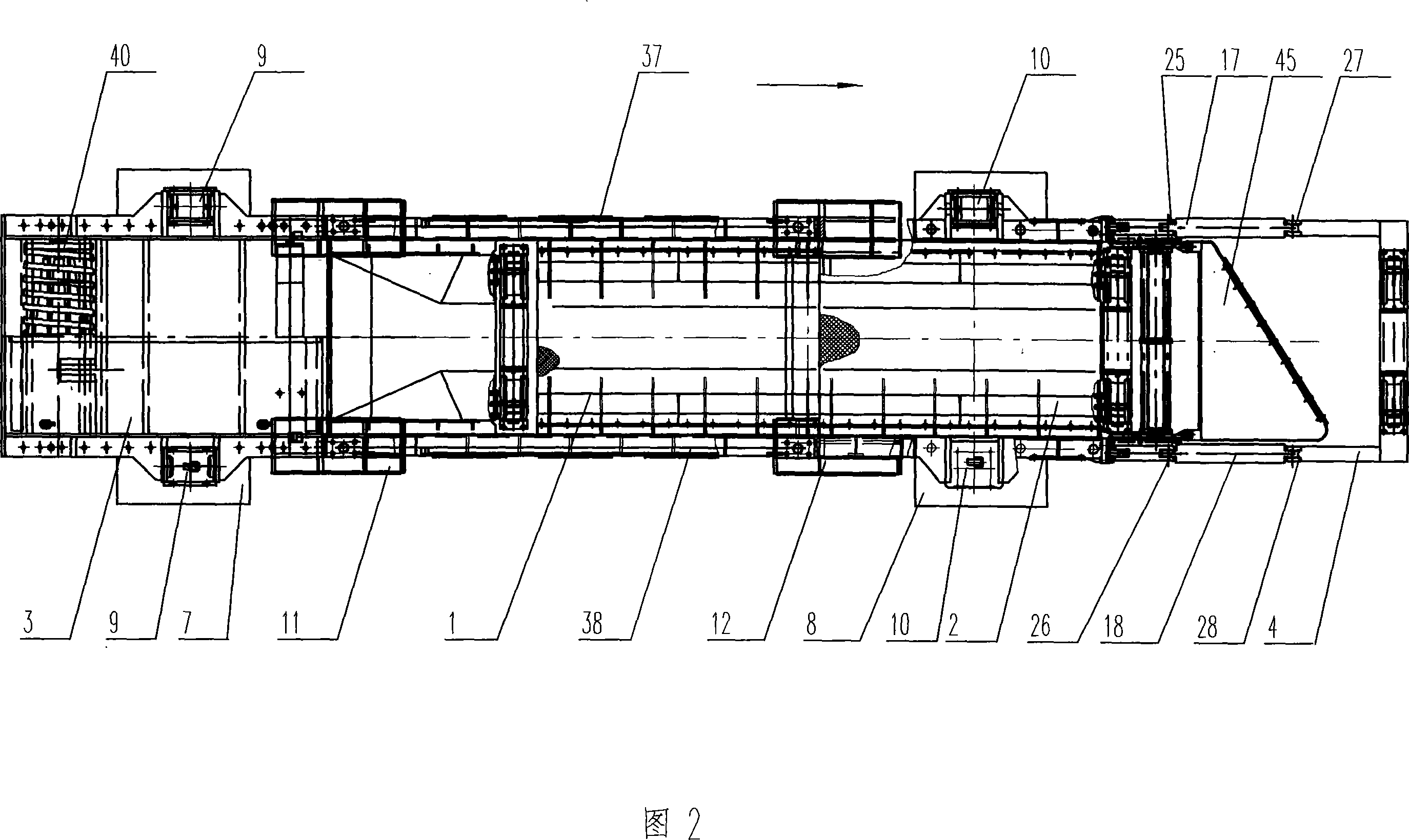

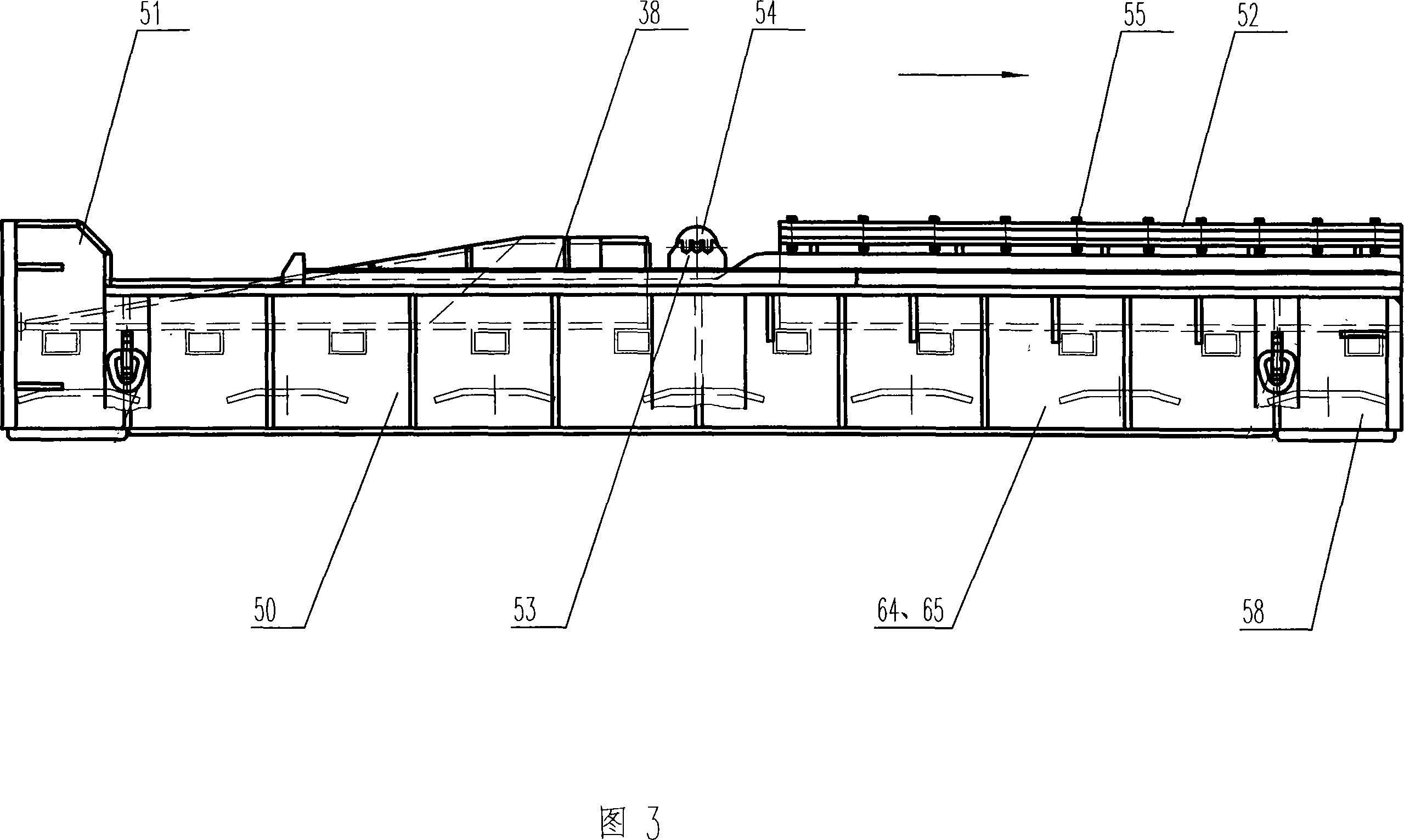

[0040] The present invention will be further described below in conjunction with accompanying drawing:

[0041] As shown in Figures 1 and 2, it is the overall structure diagram, which is composed of the middle frame 1, the head end frame 2, the tail end frame 3, the floating frame 4, and the traveling trolley 5 to form a complete overall structure, which can be separated into coal mines. Assembled to adapt to underground narrow roadway transportation; the top of the traveling trolley 5 is connected to the head 161 of the transfer machine, which is the bearing part, and must have good strength; the floating frame 4 is a transitional connection part with the belt conveyor, and can adapt to the underground ground Ups and downs; the bottom of the head end frame 2 and the tail end frame 3 are symmetrically provided with column oil cylinders 13, 14, 15, 16, which can jack up the whole machine and adjust the height, and the transportation operation is completed under the support state...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com