Steel pipe pallet car and uses thereof

A steel pipe and trolley technology, which is applied to the cranes, auxiliary devices, cranes and other directions of the trolley, can solve the problems of difficult transportation and installation of steel pipes, difficulty in turning over large-diameter steel pipes, and low production efficiency, and achieves the realization of mechanical automation. The effect of corrosion protection quality and service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

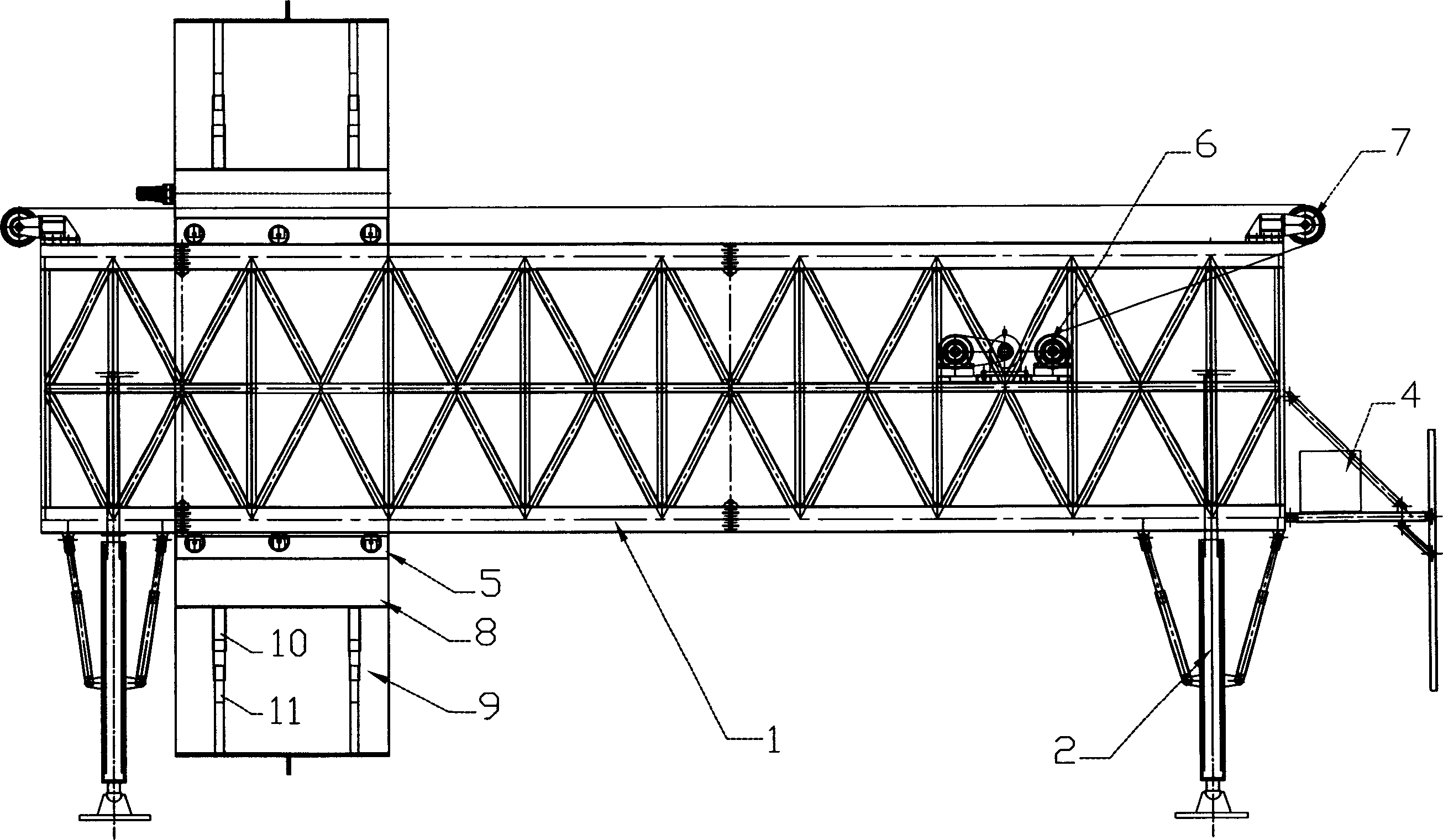

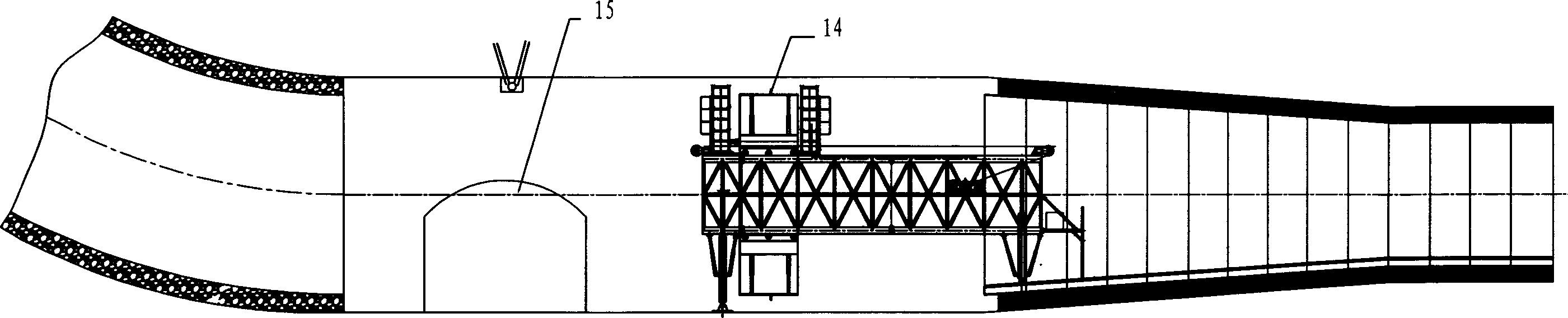

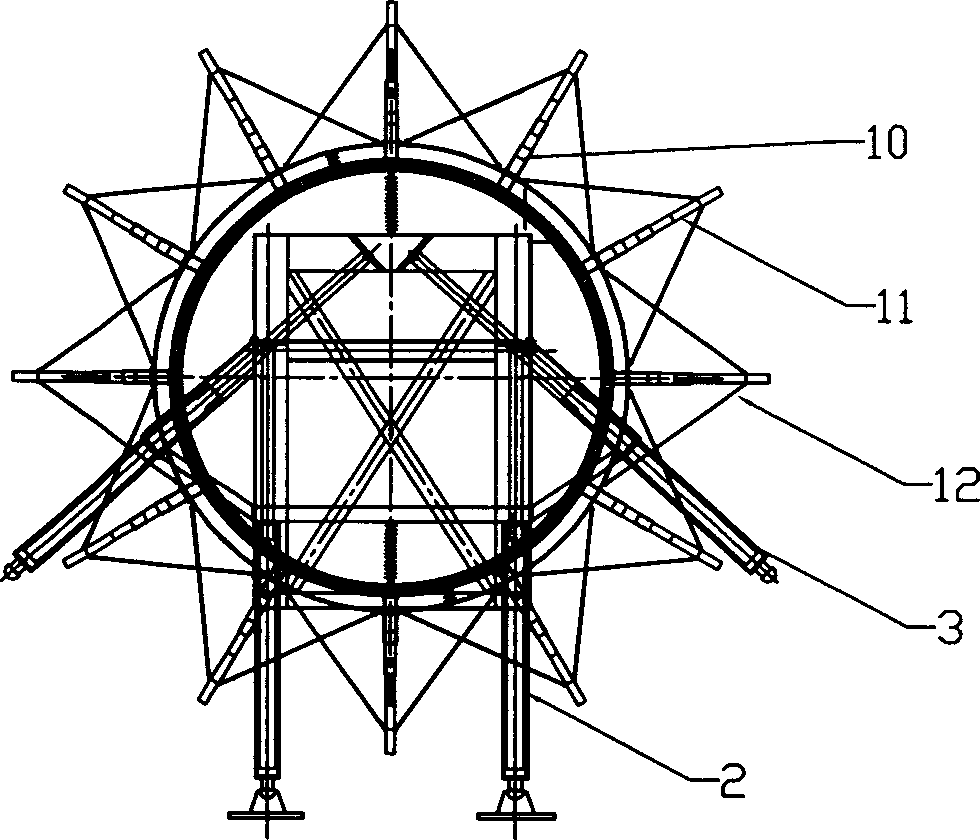

[0020] like figure 1 , 3 As shown, the front and rear ends of the main beam 1 of the steel pipe trolley are respectively equipped with outriggers 1 and outriggers 3. The contraction of the outriggers 1 and outriggers 3 is controlled by the hydraulic pump station 4, and the longitudinal walking is installed on the horizontal track of the main beam 1. Frame 5 and winch 6, through the effect of hoist 6, steering wheel 7 and steel rope, longitudinal traveling frame 5 may reciprocate on the horizontal track of main girder 1, and rotating frame 8 is mounted on longitudinal traveling frame 5 through the hole shaft. A gear drive mechanism is used to rotate the rotating frame 8 on the longitudinal walking frame 5, and 24 adjusting supports 9 are installed on the placing frame 8. The adjusting supports 9 are composed of a hydraulic jack 10 and a screw jack 11, which can be disassembled, and the sides of the adjustable supports 9 Carry out pre-tensioning with drag cable 12. In the abov...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com