Self-portable belt conveyer

A technology of self-moving and belt transportation, applied in conveyors, underground transportation, conveyor objects, etc., can solve the problems of high failure rate of scraper conveyor equipment, high labor intensity of employees, and high labor intensity, and achieve the goal of improving mechanized equipment. level, saving ineffective engineering, reducing labor intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] Describe in detail below in conjunction with accompanying drawing:

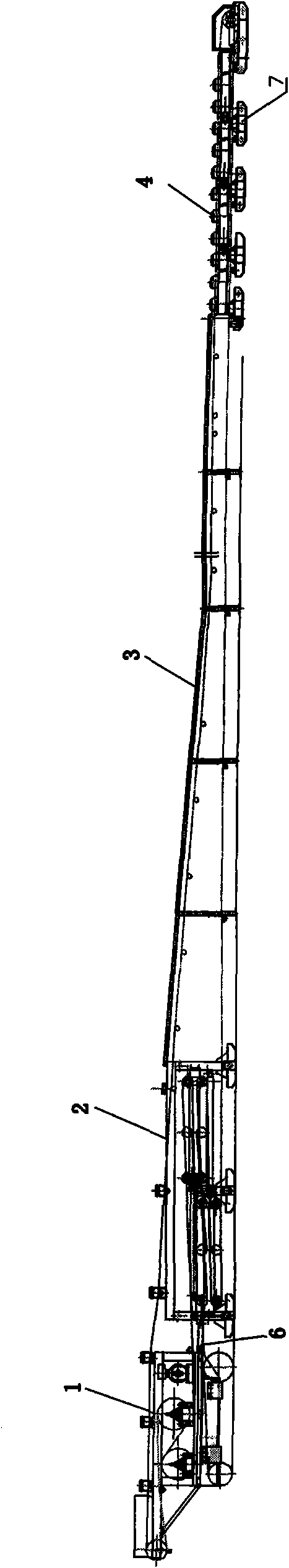

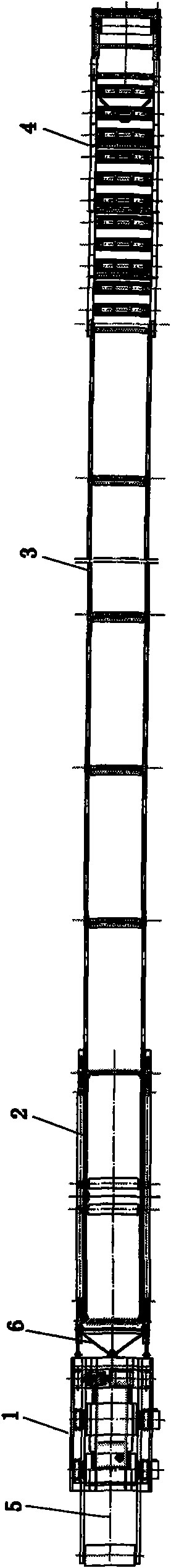

[0033] Such as figure 1 and figure 2 Shown, the self-moving belt conveyor of the present invention. The self-moving belt conveyor consists of a belt conveyor head 1, a hydraulic belt tensioner 2, a belt conveyor middle 3, a belt conveyor tail 4, a belt 5 and a drag device 6. Belt conveyor middle part and belt conveyor afterbody are to have the belt bracket of middle part and afterbody like prior art, and belt roller constitutes, and the boat-shaped device 7 that just slides is equipped with at the belt bracket leg bottom of afterbody.

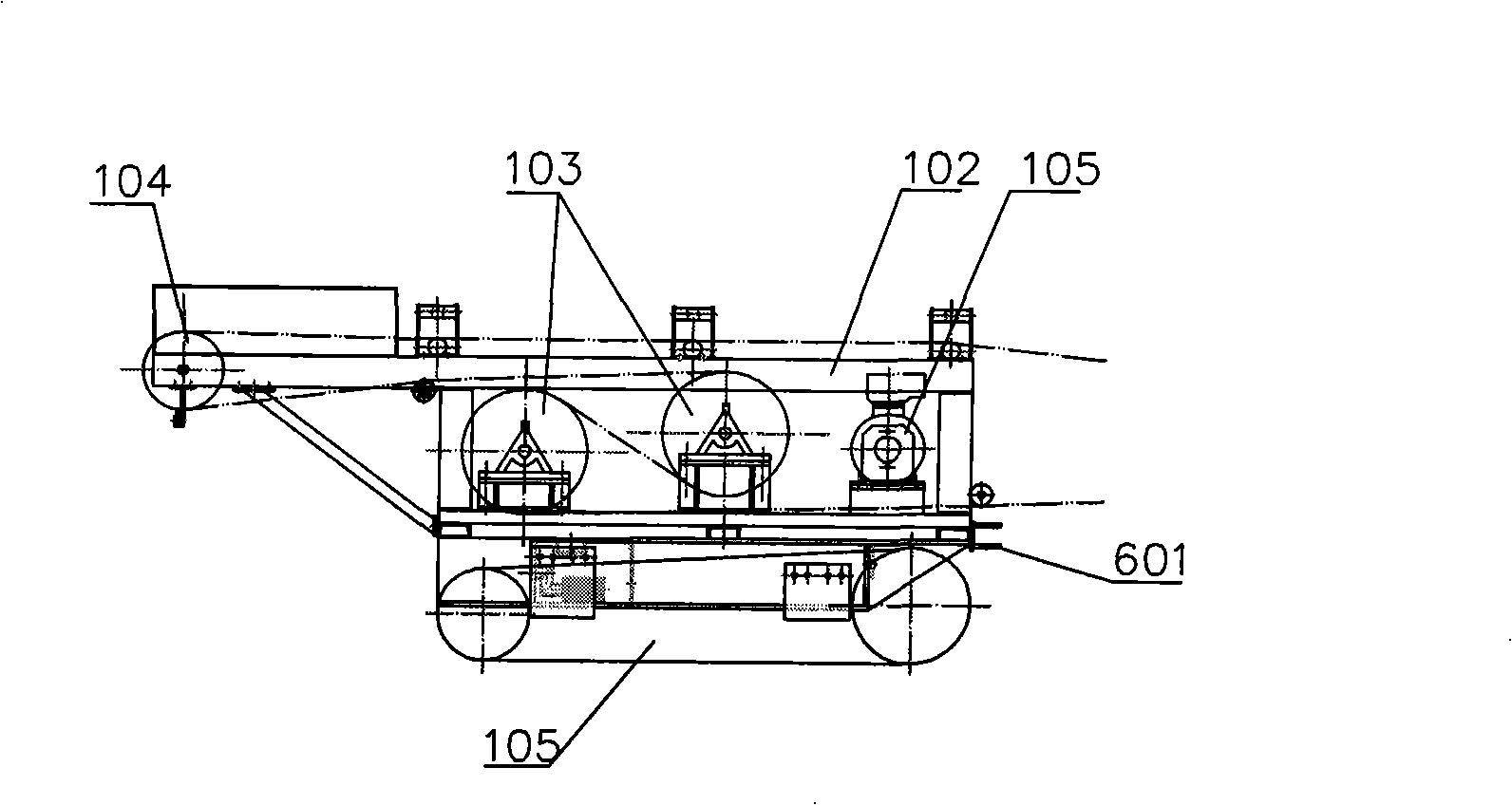

[0034] image 3 and Figure 4 As shown, the head is conveyed by belt. The belt conveyor head includes a crawler belt traveling mechanism 101, a head belt support 102, two belt drive drums 103, an unloading roller 104 and a hydraulic control system 105; A belt-driven drum is installed on the drum base on the platform and in the middle of the belt bracket of the ma...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com