Walking running device for self-advancing tail

A self-moving tail and walking device technology, applied in transportation and packaging, earthwork drilling, underground transportation, etc., can solve problems such as slow speed, unsafety, and difficulty in walking and moving

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

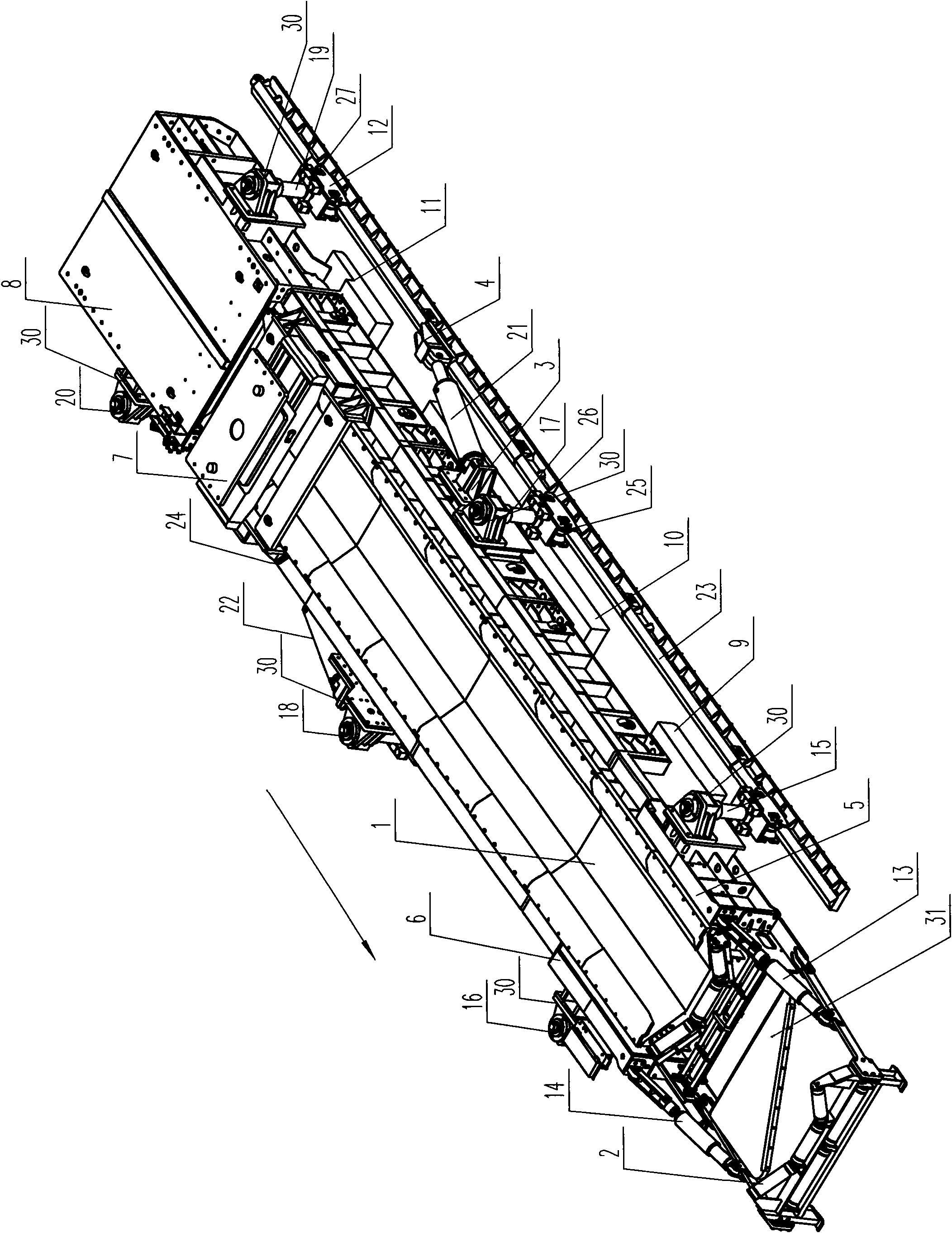

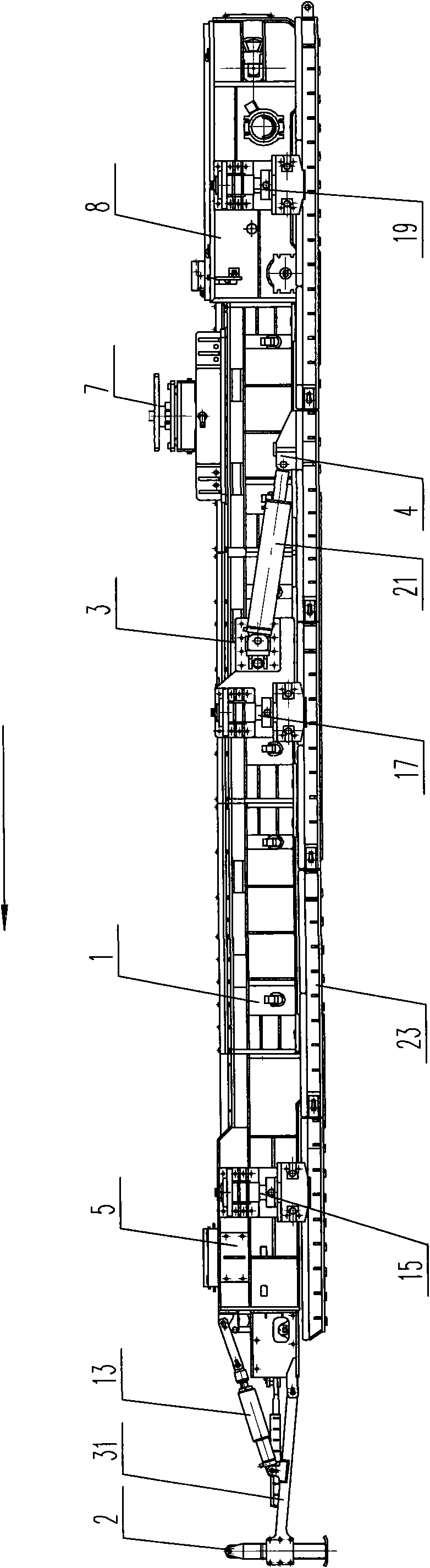

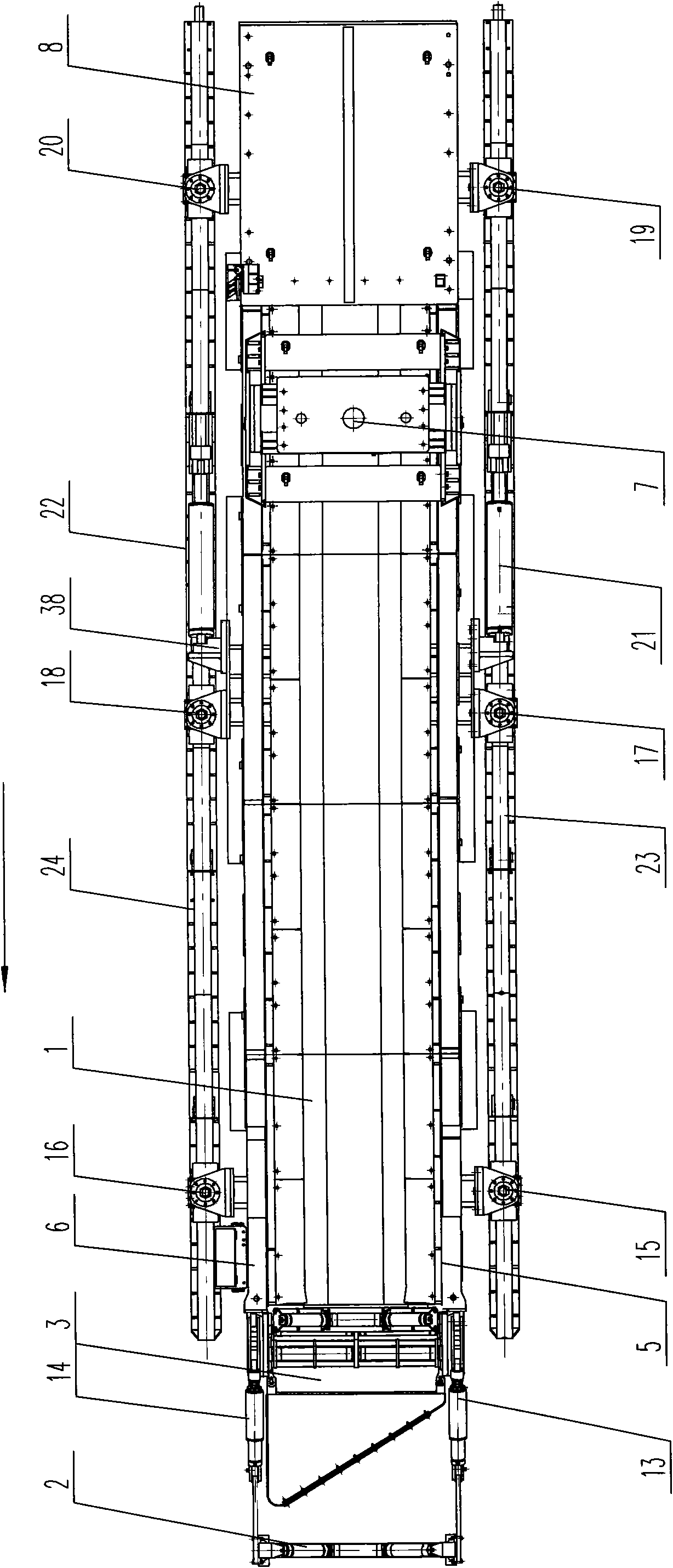

Method used

Image

Examples

Embodiment 1

[0050] The method of walking by self-moving tail is as follows:

[0051] ①. All parts of the fuselage are in a quasi-working state;

[0052] ②. The front part is connected with the belt conveyor, and the rear part is connected with the transfer conveyor;

[0053] ③. Open the hydraulic mechanism, input hydraulic oil to the forward, middle, rear, left and right lift cylinders at the same time, the piston rod of each lift cylinder extends outwards, and supports upwards simultaneously, and the fuselage and the bottom shoes are lifted up in parallel with the ground as a whole. 220mm; the left and right guide rails are load-bearing on the ground and become the thrust fulcrum of the left and right walking cylinders;

[0054] ④. Open the hydraulic mechanism, inject hydraulic oil into the left and right travel cylinders at the same time, the piston rods of the left and right travel cylinders extend out synchronously, take the left and right guide rails as the fulcrum, push the fuselag...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Lift height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com