Manual control and remote control integrated electric fork lift truck

A technology of manual manipulation and scraper, which is applied in underground transportation, vehicle parts, transportation and packaging, etc. It can solve the problems of inapplicability and limited cable length, and achieve improved safety, strong diffraction ability and convenient operation. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

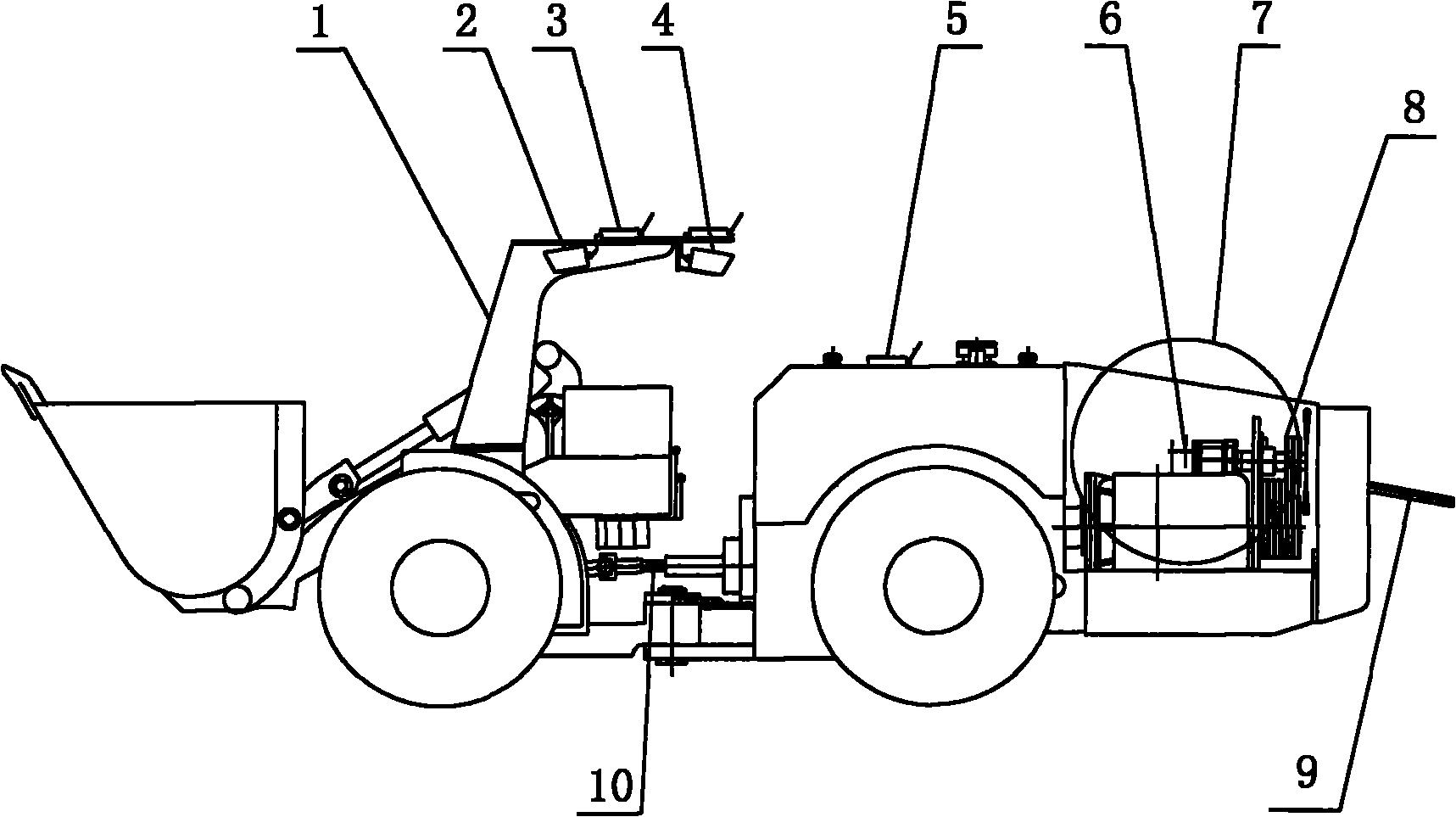

[0034] Such as figure 1 , figure 2 As shown, the electric-driven scraper 1 on the mining face is provided with an operating room, and the operating room is provided with control buttons to connect to the control system, and the power supply end of the control system is connected to the power supply cable 9 provided at the rear of the scraper. The scraper 1 on the working surface is equipped with a wireless monitoring system and a wireless control system, and the terminal console of the wireless monitoring system and the wireless control system is set at the workstation, and the wireless control system and the control buttons in the operating room are connected in parallel and interlocked to the control system. A cable reel 7 is arranged at the rear of the scraper 1, and a cable winding mechanism and a cable discharge mechanism composed of a photoelectric pulse encoder 6, an electric motor 8 and corresponding devices are arranged in the cable reel 7.

[0035] The terminal ope...

Embodiment 2

[0052] A cable winding mechanism and a cable discharge mechanism are installed in the cable drum to facilitate the extension of the working surface distance and prevent damage to the cables.

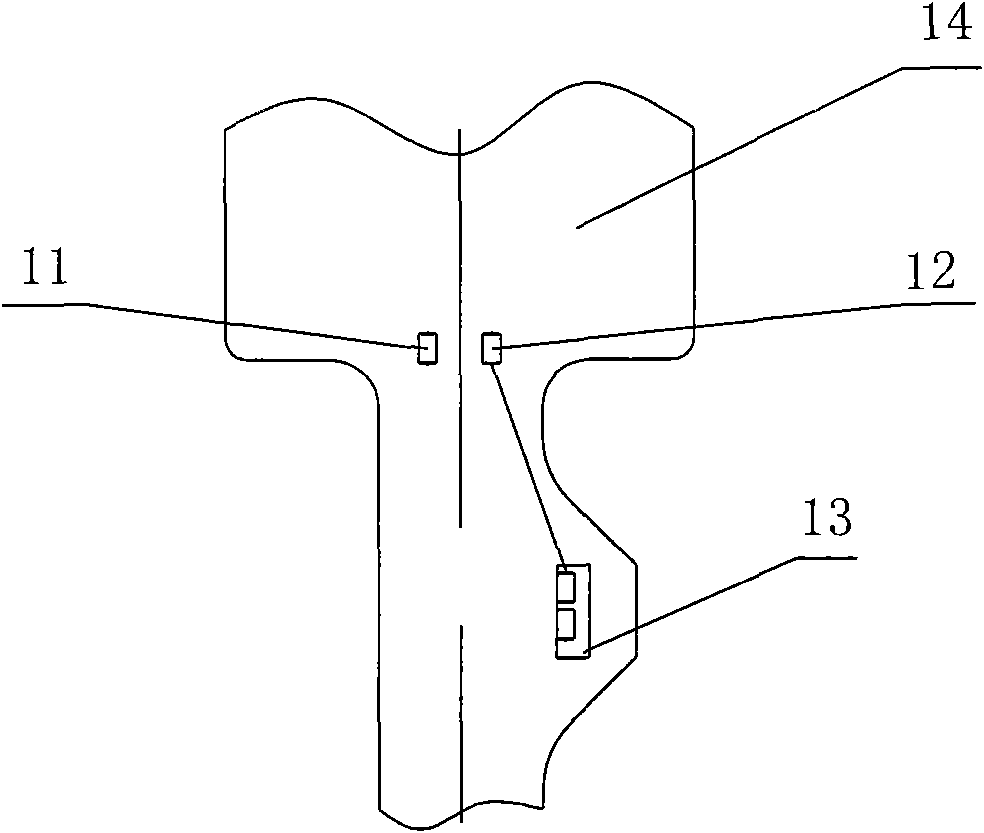

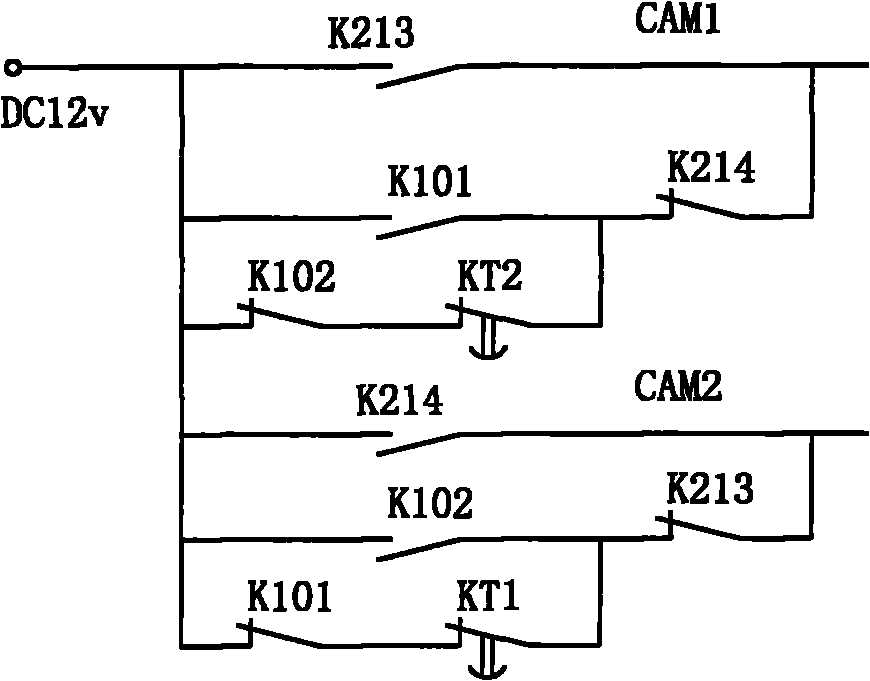

[0053] The numerical control cable arrangement mechanism includes a motor, a cable reel, a photoelectric pulse encoder and a cable arrangement control circuit connected to the photoelectric pulse encoder. The cable arrangement control circuit is connected to the motor, and the photoelectric pulse encoder is installed on the cable reel.

[0054] The synchronous coiling and unwinding mechanism includes a travel switch, an oil pump and a drive motor connected to the oil pump, and also includes an oil cylinder connected to the oil pump. The travel stopper is arranged on the oil cylinder, and the travel switch is in contact with the oil cylinder.

[0055] The original control system and lighting system of the scraper mentioned in the present invention and its arrangement are common prior art, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com