Roller failure monitoring system of belt conveyer

A belt conveyor and fault monitoring technology, which is applied in the direction of conveyor objects, conveyor control devices, underground transportation, etc., can solve problems such as dust adhered to the surface of the rollers, failure of idler bearings, loose bolts of idler frames, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The specific implementation of the present invention is aimed at the coal mine underground belt conveyor, and at the same time, taking wireless sensors as the configured sensors as an example, the specific description will be given.

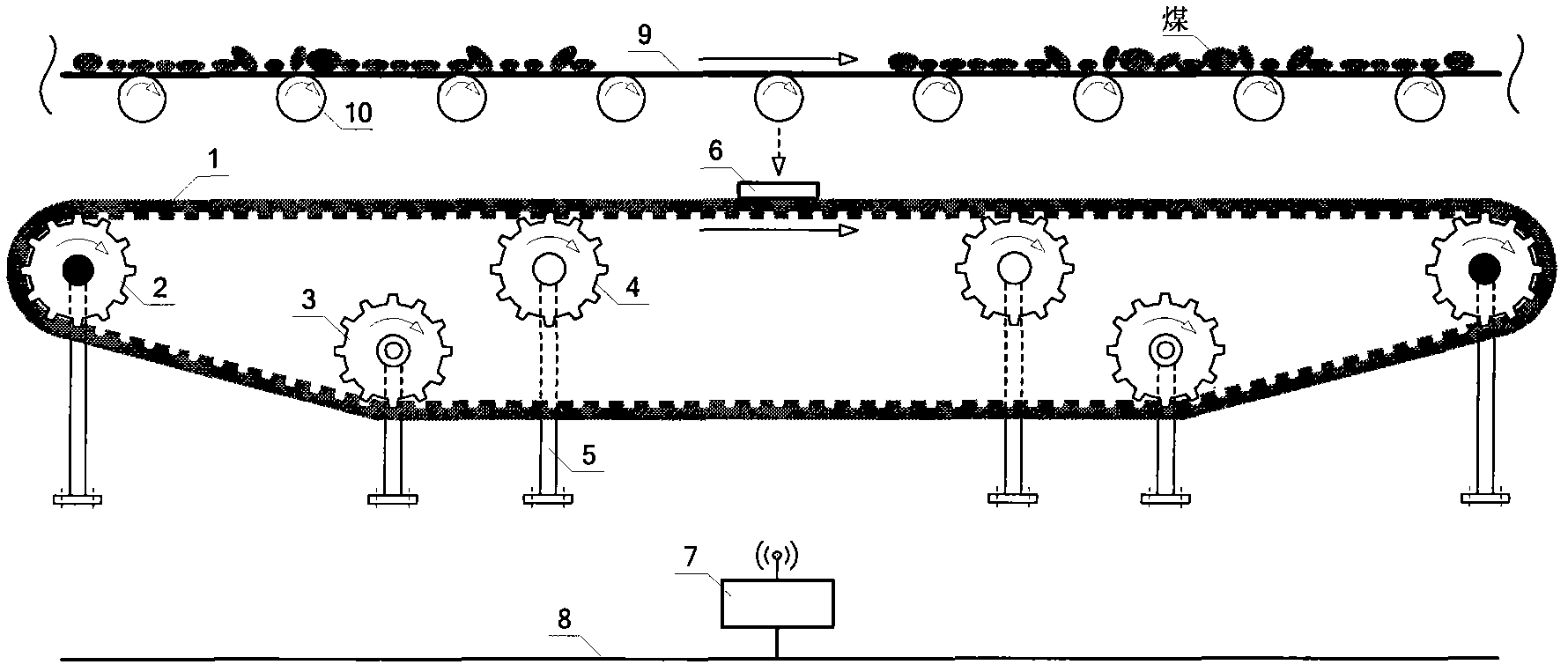

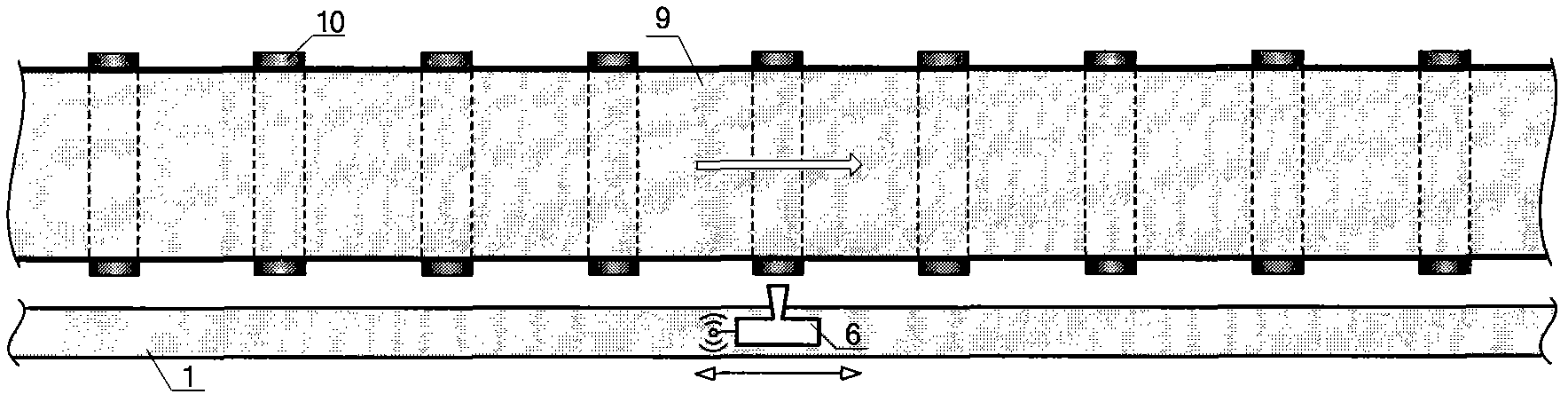

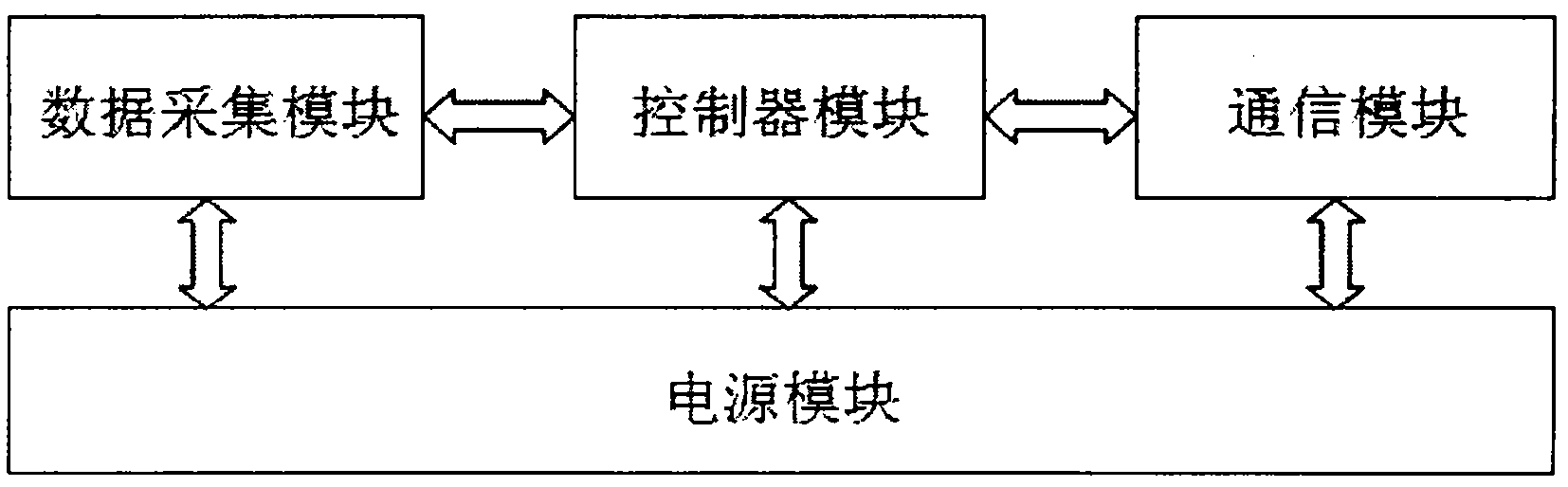

[0017] Such as figure 1 and figure 2 As shown, the present invention is provided with wireless sensor 6 and the mechanical device that moves described sensor, and described mechanical device is arranged in parallel beside the belt conveyor, and the working power supply of mechanical device adopts the power supply of underground substation; Belt conveyor belt 9 There are multiple groups of belt conveyor idler rollers 10 below, each idler roller is perpendicular to the moving direction of the belt, and is used to support the conveyor belt and the weight of the material; the moving direction of the wireless sensor 6 is parallel to the conveying direction of the belt conveyor belt 9 The mechanical device can perform intermittent operation. T...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com