Tunnel pipe transporting mounting vehicle

A technology for installing vehicles and pipelines, which is applied in the directions of transporting passenger cars, transportation and packaging, and underground transportation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

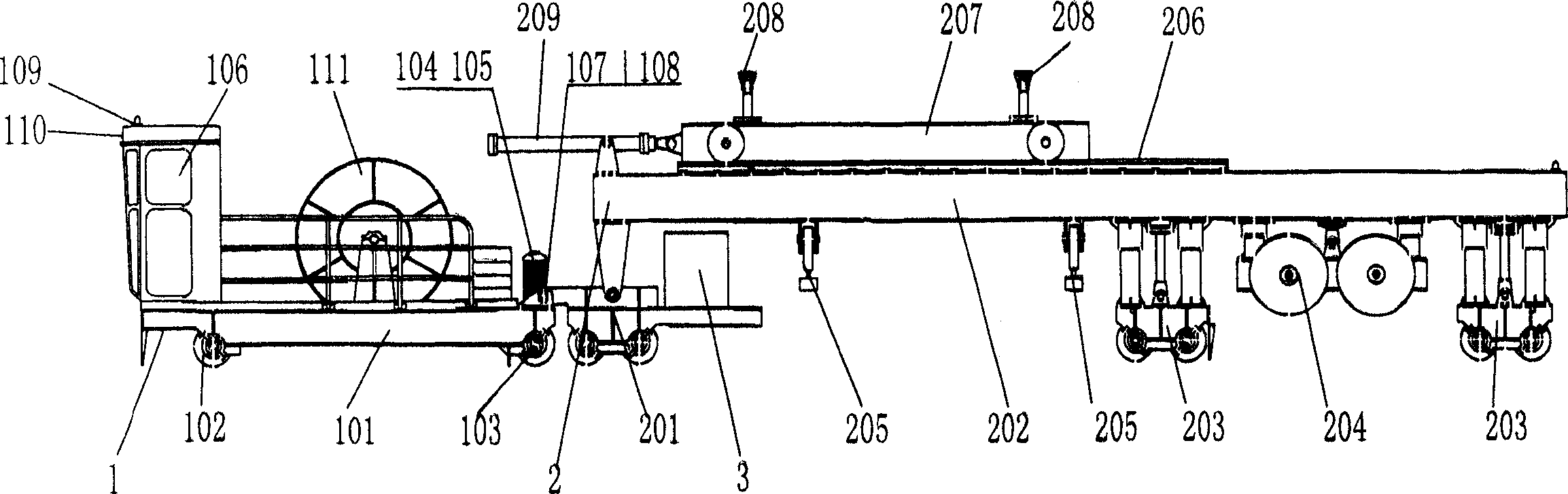

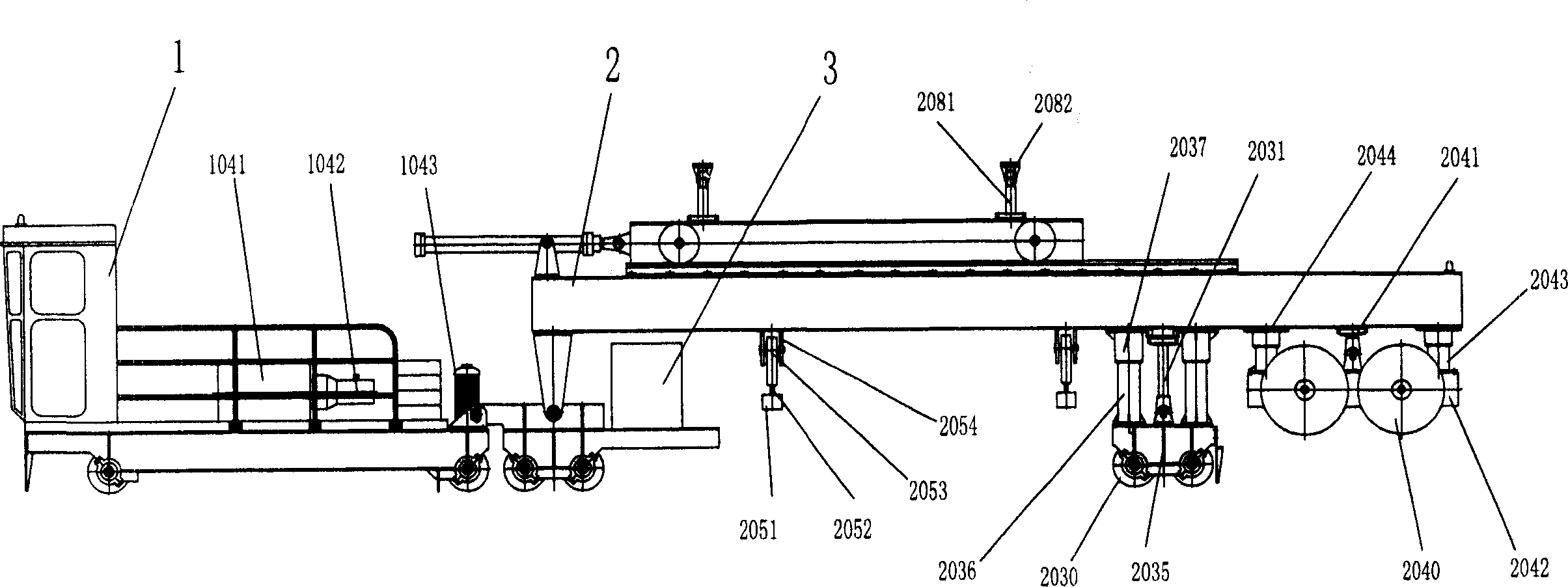

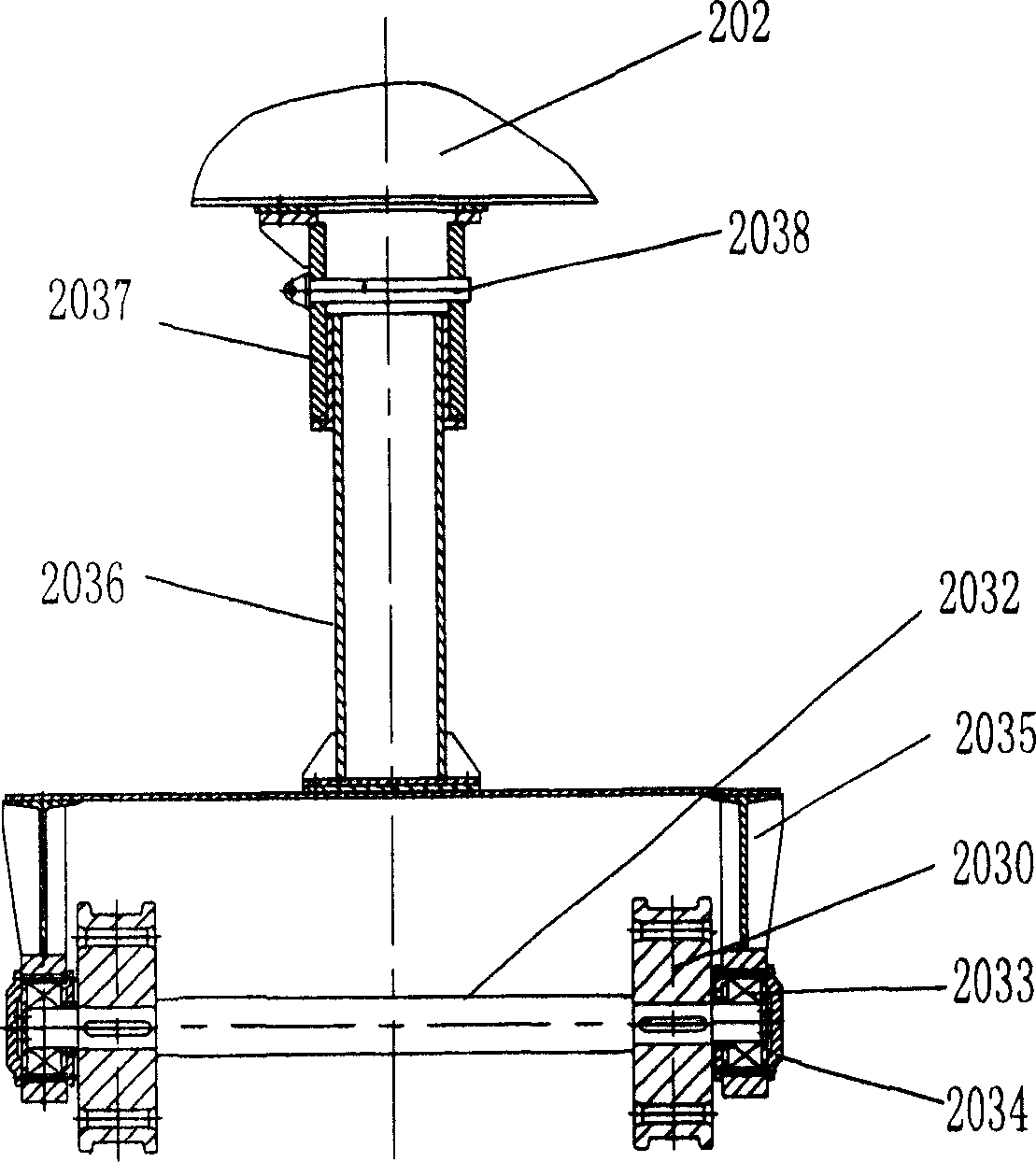

[0035] figure 1 As shown, the tunnel pipeline transport installation vehicle composed of a tractor with a motor and a cable reel and a load-carrying vehicle with two sets of lifting wheels and a set of lifting tires is composed of a tractor running on a track installed in the tunnel 1 and the piggyback car 2 are composed of two parts. The tractor comprises: chassis 101, driven wheel set 102 installed on the chassis and driving wheel set 103 and power unit 104 and speed reducer 105 for driving the driving wheel set, driver's cab 106 installed at the front of the chassis, and a driver's cab 106 installed at the rear of the chassis. The hinged seat 107 and the pin shaft 108 of the traction truck, the warning signal lamp 109 and the lighting lamp 110 arranged on the driver's cab; the power device installed on the tractor is an electric motor, and the cable reel device installed on the chassis of the tractor 111. The electric motor is connected with the reducer fixed on the chass...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com