Main shaft skip weight-measuring device for coal supply machine

A technology of coal feeder and weighing device, applied in conveyor control device, measuring device, conveyor and other directions, can solve the problems of limited space, overloaded elevator, large volume of fixed weight device, etc., and achieves convenient installation and stable operation. , the effect of low noise

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

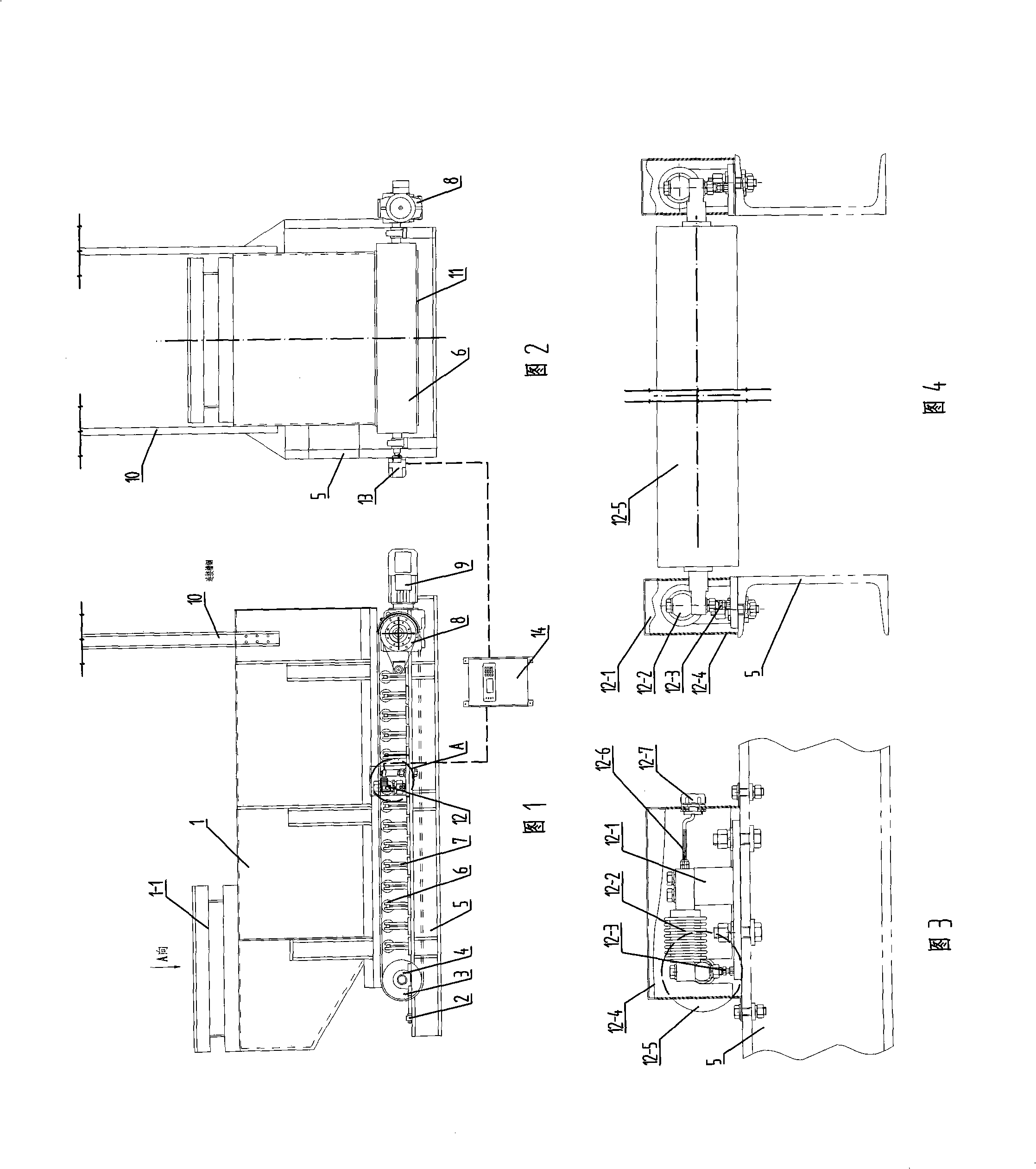

[0017] As shown in Figure 1 and Figure 2: a coal feeder-type main well skip weighing device, including a coal feeder and a weighing device installed on the coal feeder; the coal feeder includes: a belt conveyor, Guide groove 1, feeding port 1-1; described belt conveyor comprises: frame 5, driving roller 8 installed on the upper end of frame 5 through bearing seat 4, driven roller 3, speed regulating motor 9, conveyor belt 11 and tape tensioning device 2, a plurality of rollers 6 installed on the upper end of frame 5 through bracket 7; the guide groove 1 is arranged on the upper part of the conveyor belt 11, and the lower part of the guide groove 1 is connected with the frame 5, and the upper part It is connected with the derrick through the connecting beam 10; the upper part of the guide groove 1 is provided with a feed port 1-1; it is characterized in that: the weighing device includes: an instantaneous weighing device 12 connected with the conveyor belt 11, and a driven rolle...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com