Turnout remote central control device for mine inclined drift track transportation and detection control method thereof

A rail transportation, centralized control technology, applied in program control, transportation and packaging, electrical program control, etc., can solve problems such as many uncertain factors, backward technology, and no technical detection methods, and achieve the effect of ensuring the accuracy of control.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

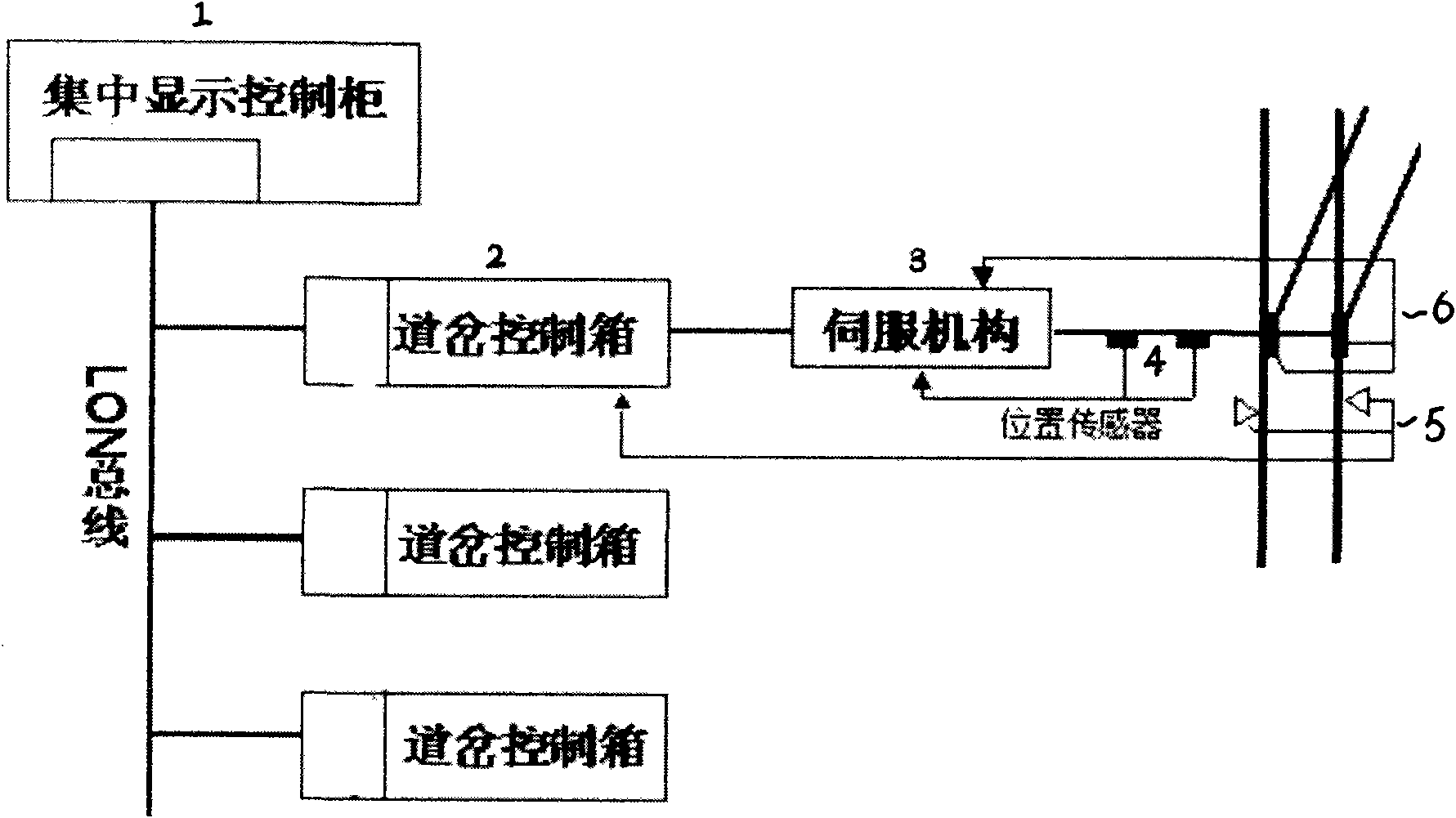

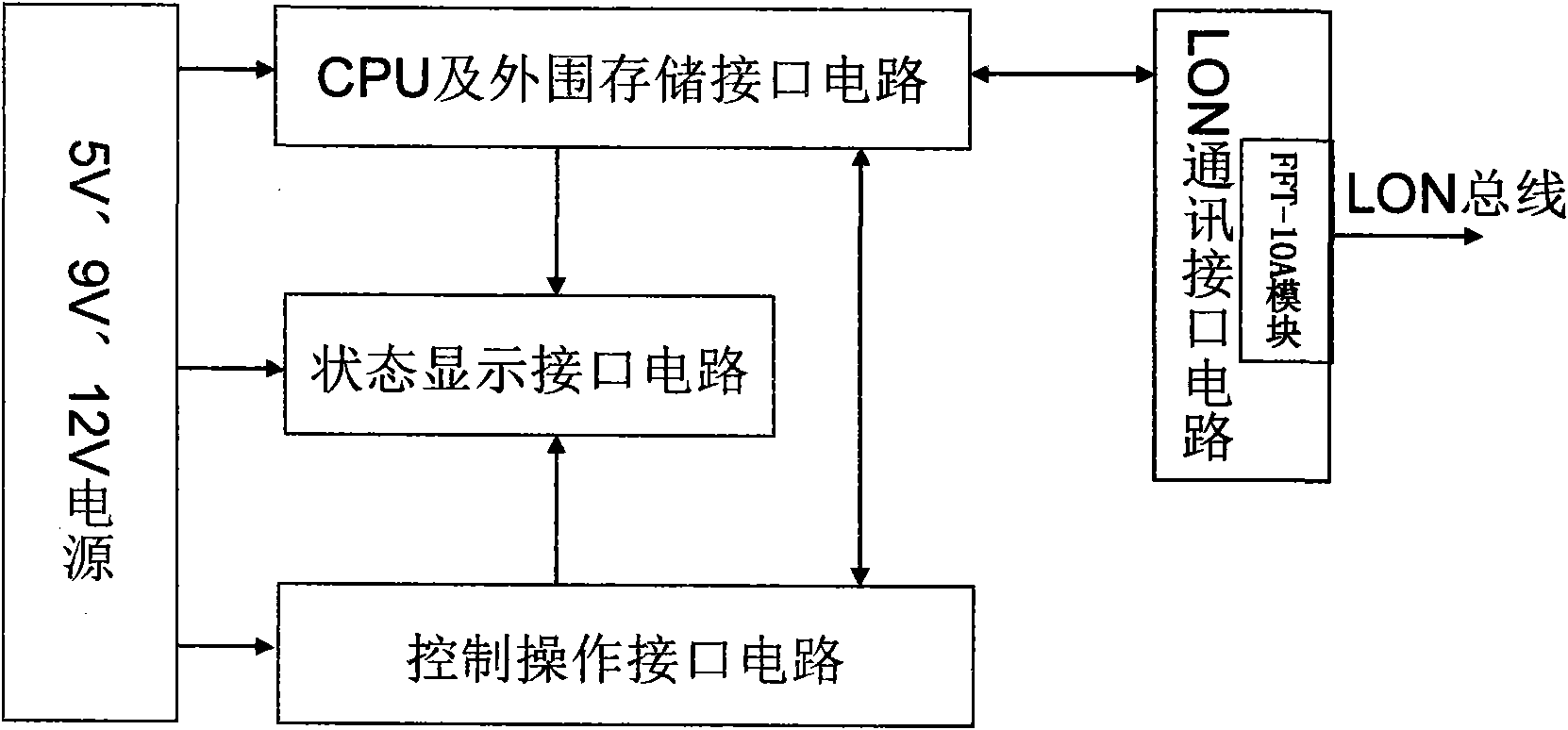

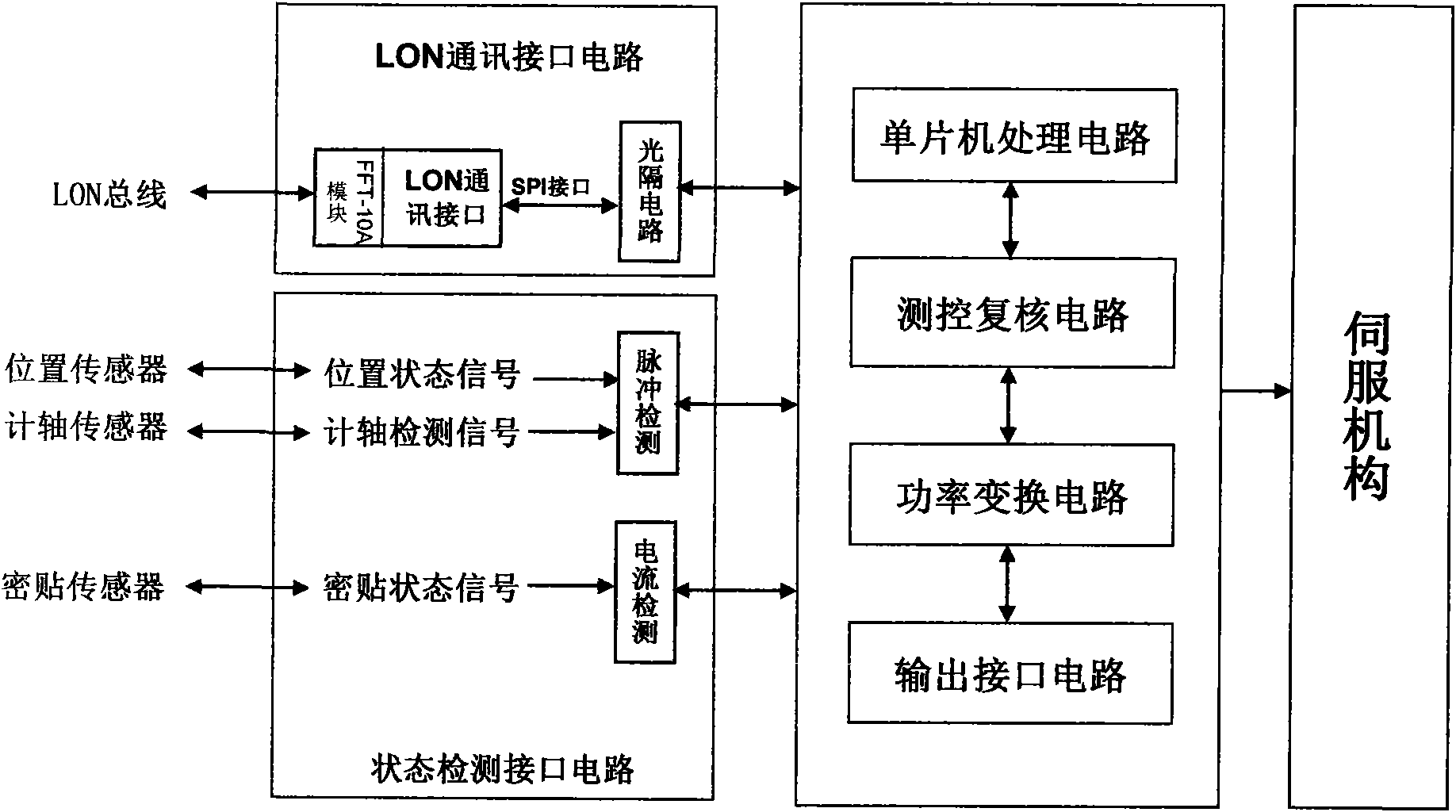

[0021] Such as figure 1 The shown remote control technology for turnouts in mine inclined lane rail transportation includes a centralized display control cabinet (1) installed in the underground monitoring room of the mine, a servo mechanism (3) connected to the turnout tip and its supporting position sensor (4), A close-fitting sensor (6), an axle counting sensor (5) installed on the track, and a turnout control box (2) installed in the avoidance chamber near the servomechanism (3). Centralized display control cabinet (1) and turnout control box (2) use LON bus communication, all node transceivers use FTT-10A, between turnout control box (2) and servo mechanism (3), position sensor (4) A closed-loop control circuit is formed. The switch control box (2), the track axle counter (5), and the close sensor (6) are all two-wire current-type detection interfaces, and each device is connected in sequence according to the diagram. It includes a centralized display control cabinet (1)...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com