Sleeper replacing implement

A sleeper and machine tool technology, which is applied in the field of sleeper replacement machines and tools, can solve the problems of increased labor management intensity, uneconomical sleepers, and high cost, so as to improve accuracy and work efficiency, improve operation safety, and facilitate transition Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The present invention will be further described below in conjunction with accompanying drawing.

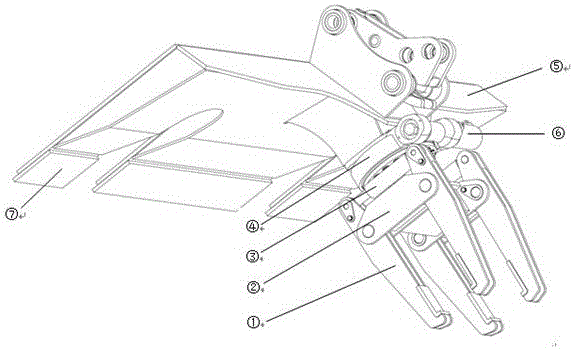

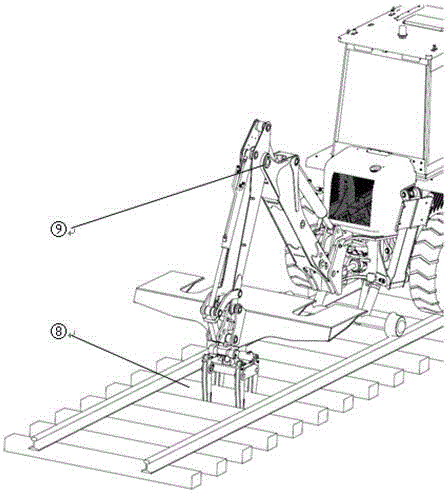

[0019] like figure 1 As shown, a sleeper replacement tool of the present invention includes a clamp 1 for clamping a sleeper, a rotary mechanism 4 and a scraper 5 for scraping gravel; The connecting part of the working mechanism, the scraper 5 is connected to the rotary mechanism 4; the rotary mechanism 4 is connected to the support frame 2, and the motor 6 is installed on the rotary mechanism 4 to drive the rotary mechanism 4 to rotate; the clamp 1 is installed on the support frame 2 superior.

[0020] On the basis of the above structure, there are two pairs of clamps 1 in the present invention, which are connected to both ends of the oil cylinder 3; the oil cylinder 3 controls the opening and closing angles of the clamps 1 . It can adapt to sleepers 8 of different materials and specifications; the bottom of the clamp 1 is shaped like a hook. Prevent the sleeper 8 from ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com