Unmanned storage system and warehouse output and input method

A warehousing system and shelf technology, applied in the field of unmanned warehousing system and inbound and outbound, can solve the problems of high cost, less reserved space, and high deployment cost, and achieve the effect of small load capacity, short implementation period, and efficient transportation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

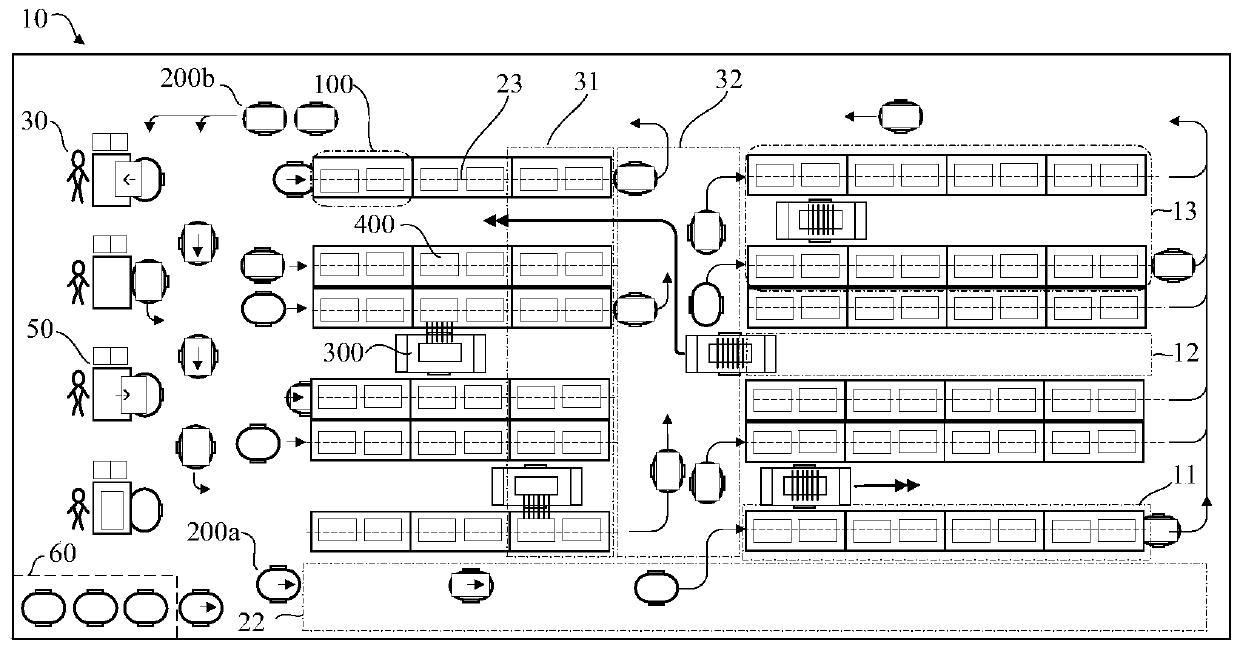

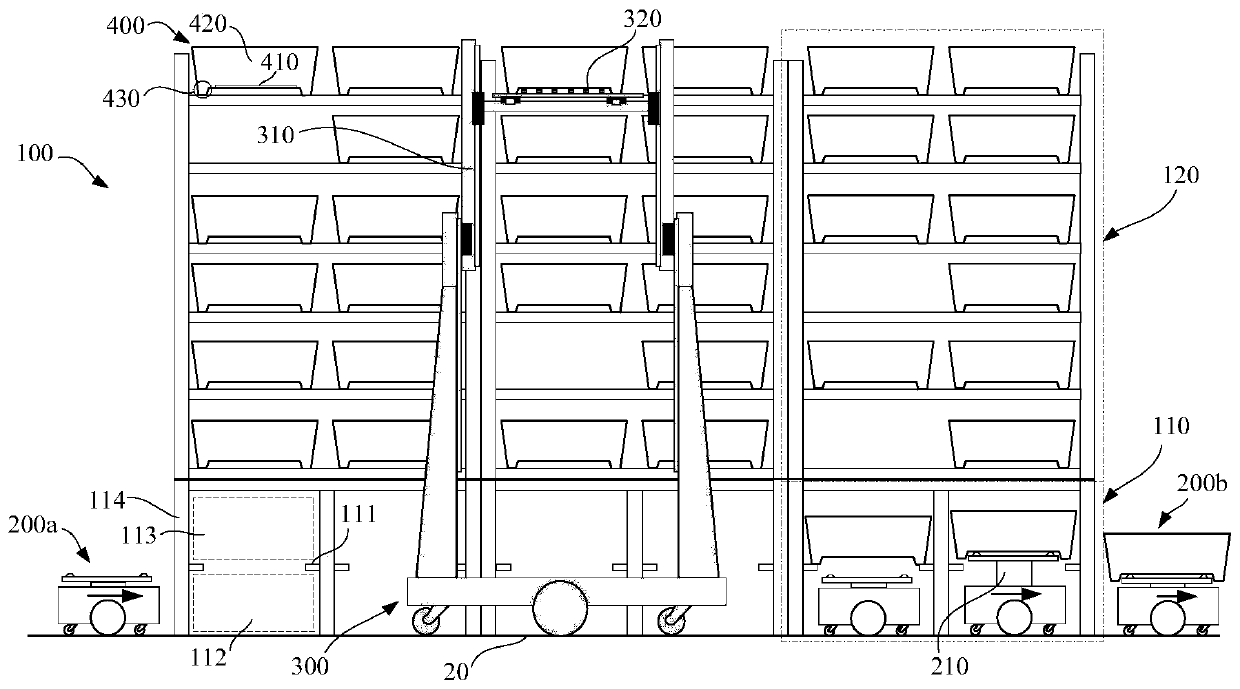

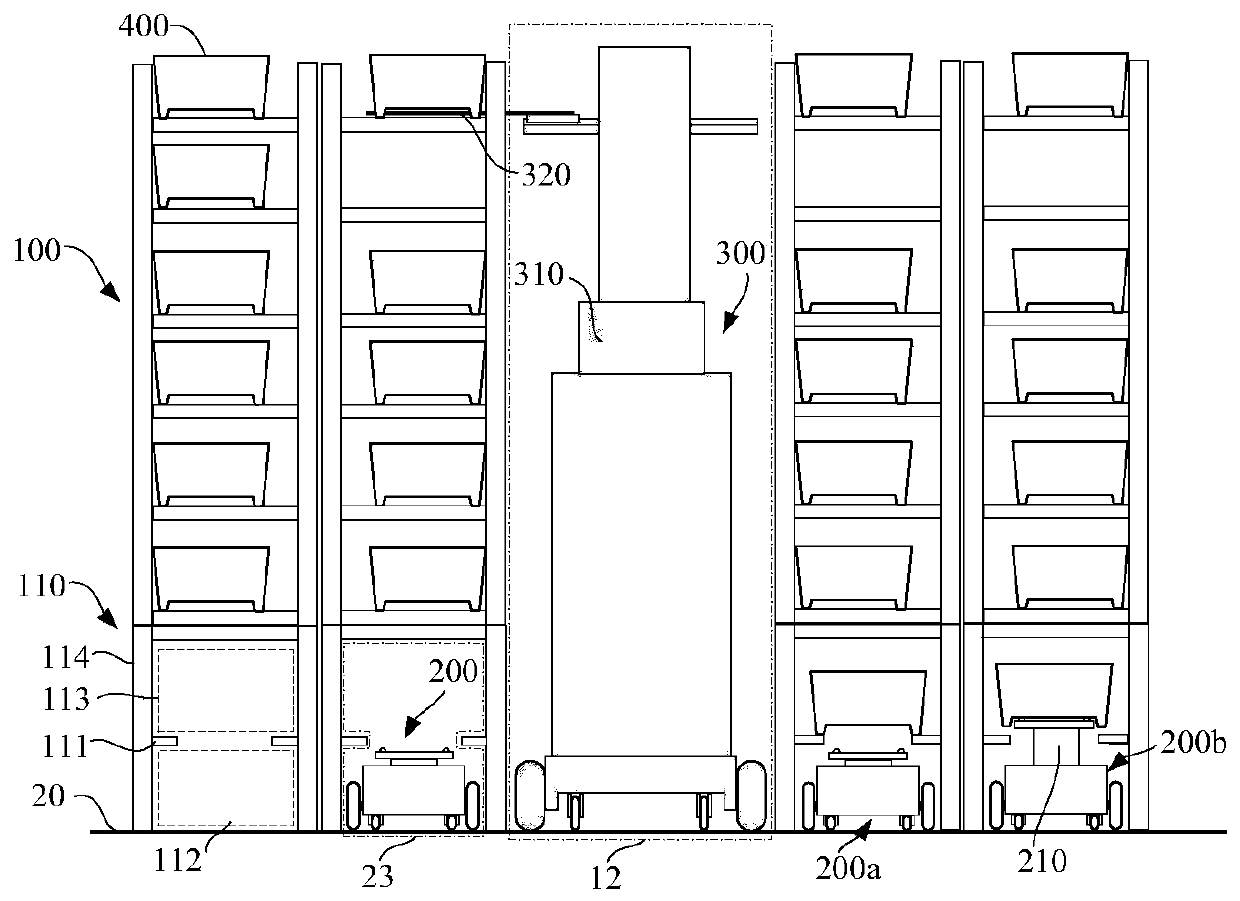

[0035] Such as figure 1 As shown, Embodiment 1 of the present invention provides an unmanned storage system based on a mobile robot and a cache space and a method for entering and exiting the warehouse, which involves a storage sorting system. The storage system 10 includes a scheduling control system, not shown in the figure, and multiple Shelves 100, multiple automatic guided vehicles 200, multiple stackers 300, and optional sorting workstations 50, etc. The AGV 200 and the stacker 300 are generally powered by built-in batteries.

[0036] Each automatic guided vehicle 200 and stacker 300 communicates with the dispatch control system through a wireless communication network. The automatic guided vehicle 200 and stacker 300 rely on their own sensors, such as laser radar, visual sensor, magnetic line reader, etc., And with the help of navigation markers arranged in the warehouse, such as reflective strips, QR codes, RFID patches, etc., automatic movement and positioning can be...

Embodiment 2

[0061] Figure 7 It is a schematic diagram of a typical fixed structural support on the channel support frame in Example 2 of the present invention. which for Figure 7 In the channel support frame shown in a, the standardized container 400 can be docked above the support and can move in the row direction and the column direction. The advantage of adopting this structure is that the path planning of the automatic guided trolley is more flexible; and for Figure 7 In the channel support frame shown in b, the standardized container 400 can be docked on the support member, but can only move along the column direction parallel to the long metal plate. The advantage of adopting this structure is that the rigidity of the channel support frame can be improved.

[0062] Figure 8 It is a schematic diagram of the overall layout of the item sorting system in Embodiment 2 of the present invention and the schematic diagram of the principle when the automatic guided trolley runs along th...

Embodiment 3

[0067] Figure 9 It is a schematic diagram of the overall layout of the item sorting system in Embodiment 3 of the present invention and the schematic diagram of the principle when the automatic guided trolley runs along the row direction in the dedicated row aisle for the trolley, and runs along the column direction under the shelves. This embodiment generally adopts the same as embodiment 2 such as Figure 7 Fixed structural supports shown.

[0068] The difference from Embodiment 2 is that in this embodiment, several lanes 21 dedicated to trolleys are added between two sets of rack lane combinations 13 . Figure 8 Taking the addition of a laneway 21 dedicated to trolleys as an example, the automatic guided trolleys 200 enter the laneway from one end in sequence, and after reaching the designated rack row, turn in situ, and then enter the corresponding laneway 33 . The counterclockwise arrows and clockwise arrows on some of the dollies in the figure indicate that the dolly ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com