Efficient rotary puncher

A puncher and efficient technology, applied in metal processing and other directions, to avoid position mismatch and save manpower

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] It should be noted that, in the case of no conflict, the embodiments of the present invention and the features in the embodiments can be combined with each other.

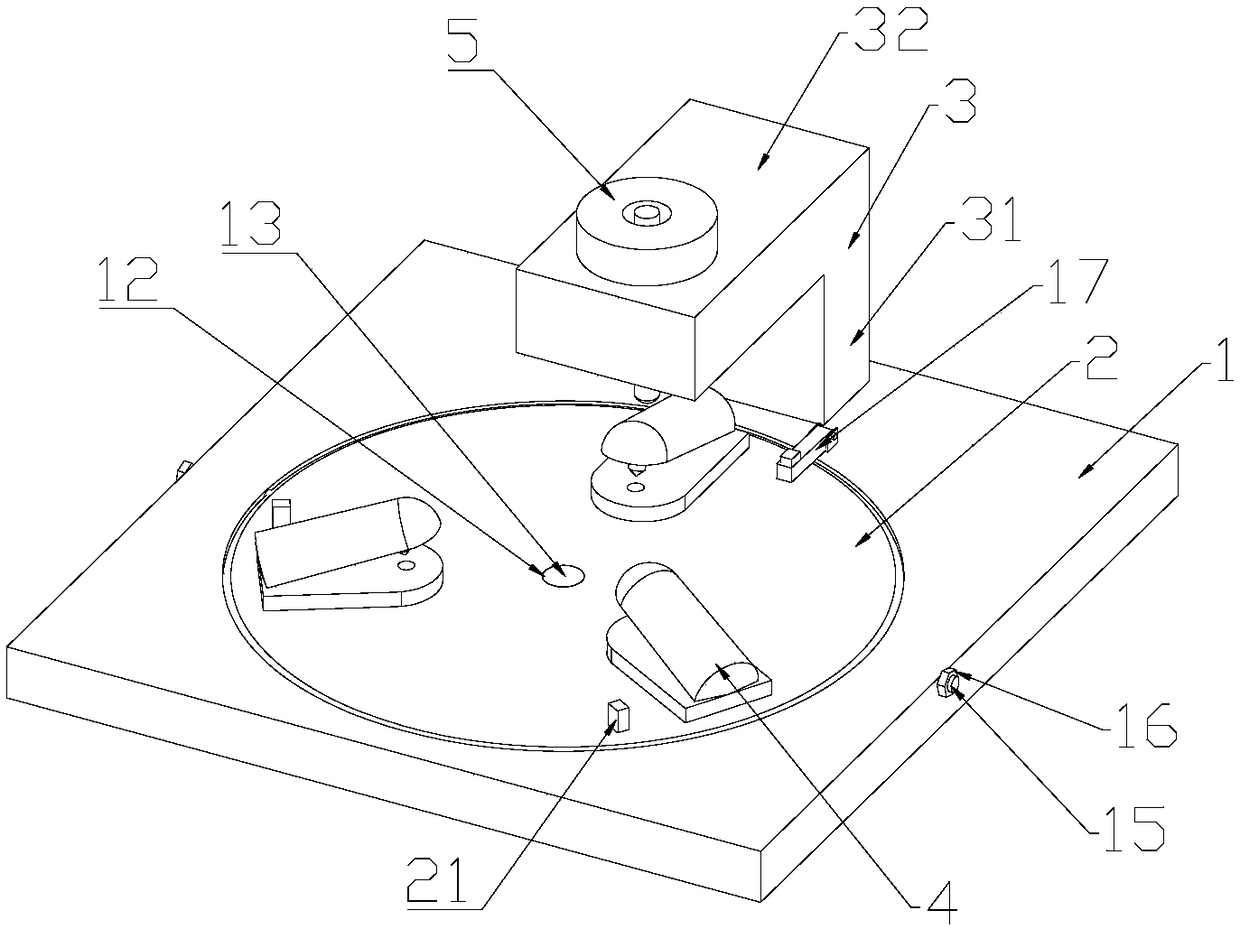

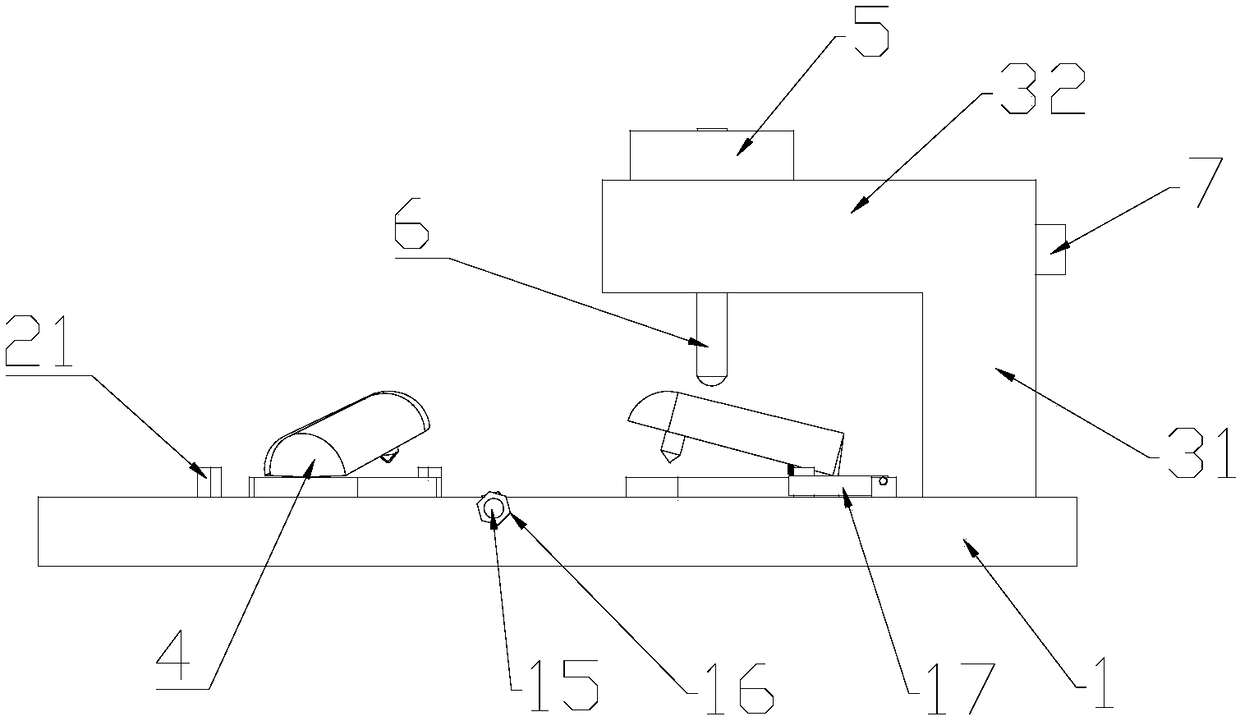

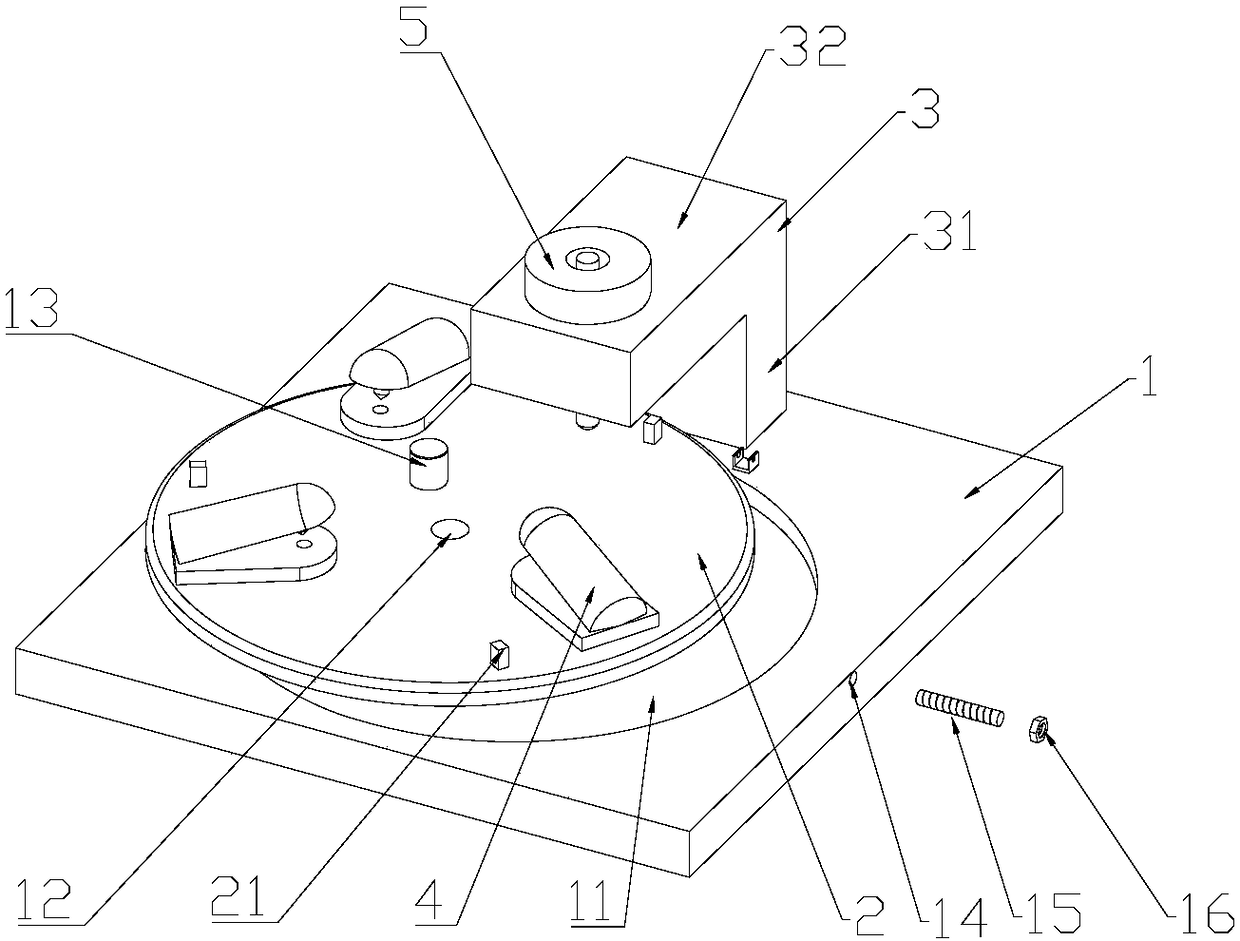

[0025] The following will refer to the attached Figure 1-5 The invention will be described in detail in conjunction with the embodiments.

[0026] Such as figure 1 , Figure 5 As shown, a kind of high-efficiency rotary puncher comprises workbench 1, and described workbench 1 comprises rotary table 2 and support 3, and described rotary table 2 is provided with puncher 4, and described puncher 4 is with The rotation table 2 is equiangularly distributed in the circumferential direction of the center of the circle. The punching machine 4 is provided with punching pins 43 of different specifications to meet the needs of punching holes of different sizes. The ends of the punching pins 43 are conical.

[0027] Such as Figure 5 As shown, the punching machine 4 includes a pressing cover 41 and a base 42, the si...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com