Automatic COF coil punching device

A technology of automatic punching and punching dies, which is applied in the field of automatic punching equipment for COF coils, can solve the problems of no punching equipment, etc., achieve the effect of improving work efficiency and automation, reducing the rate of defective products in production, and improving the yield rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

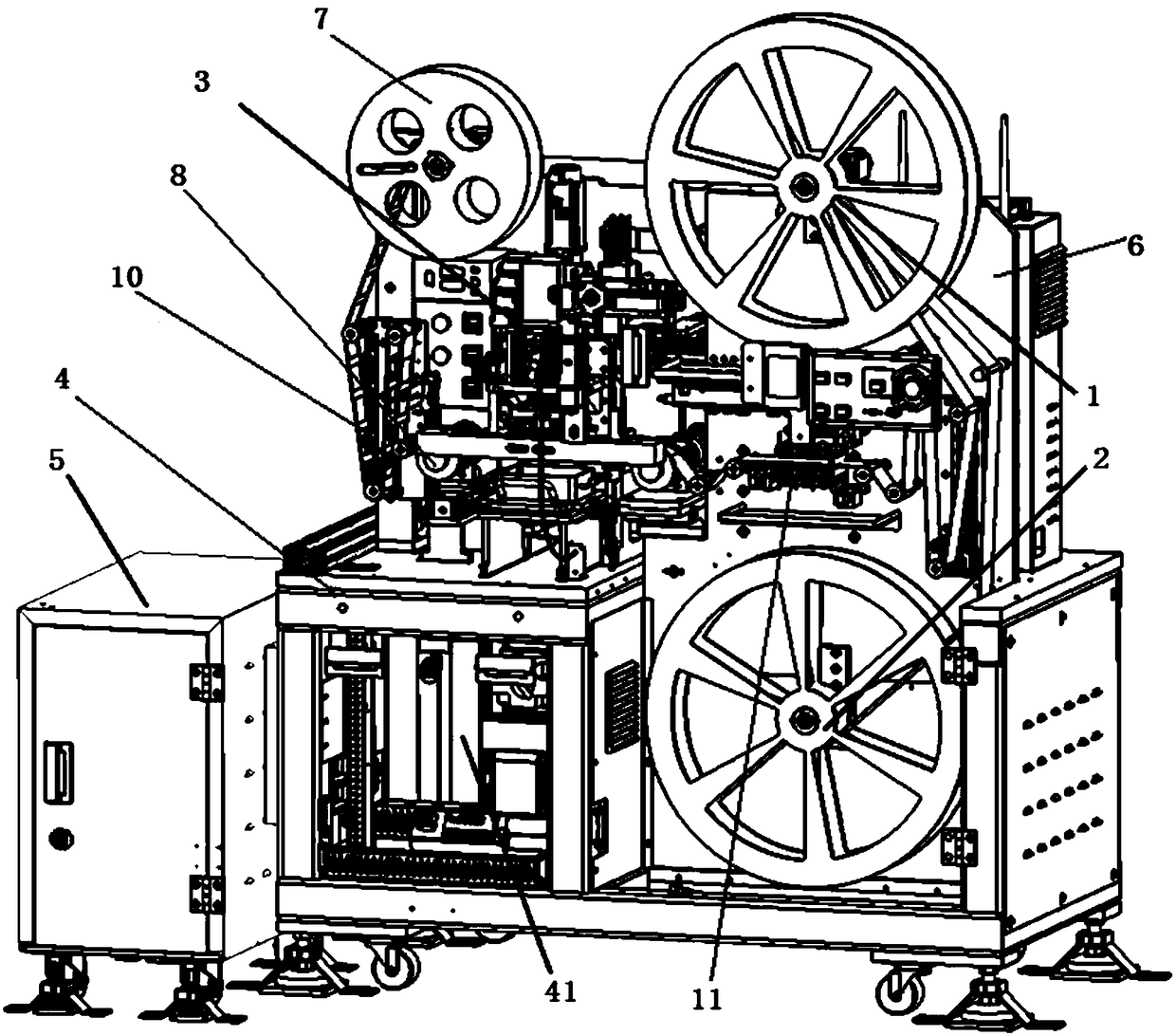

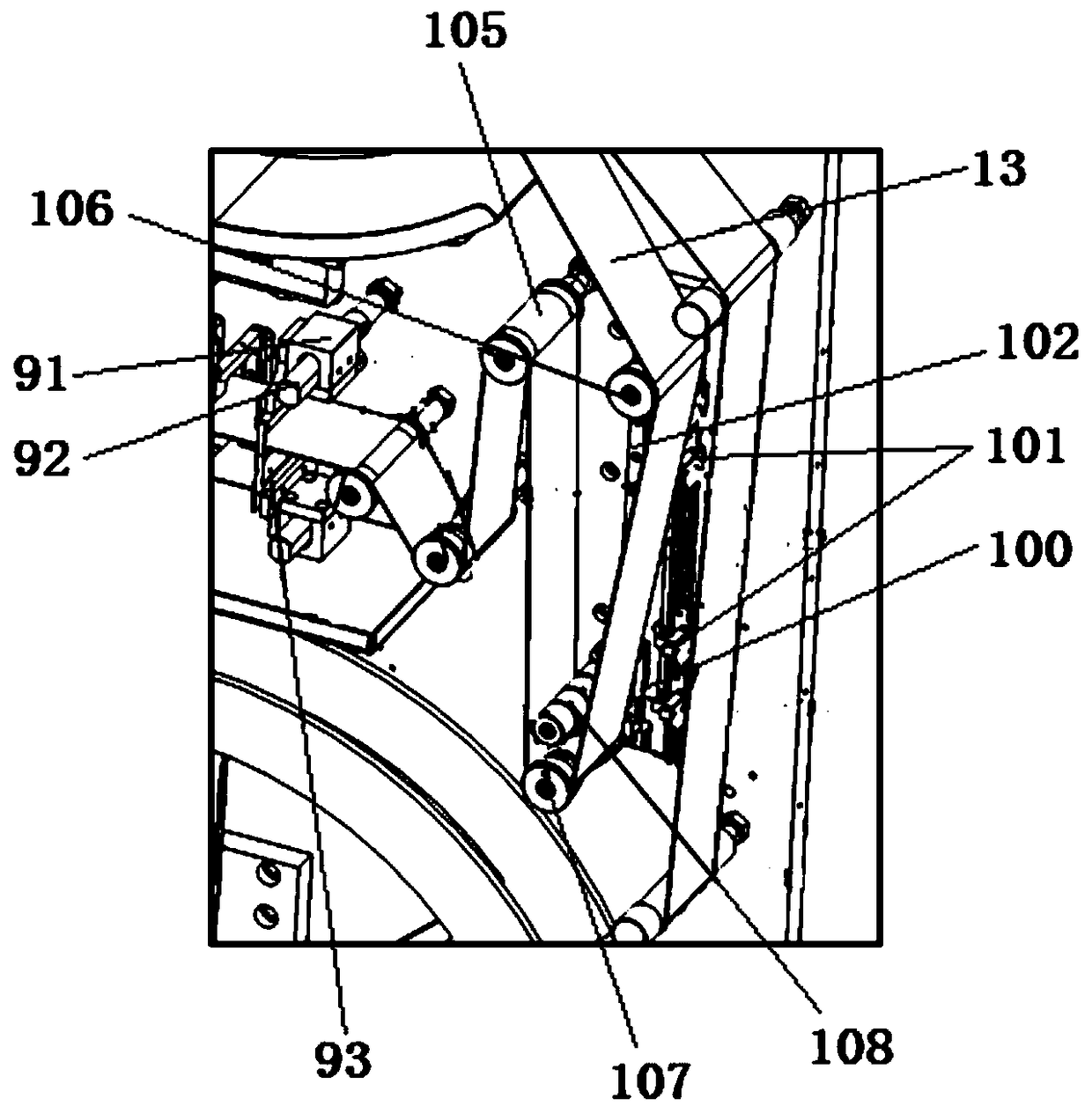

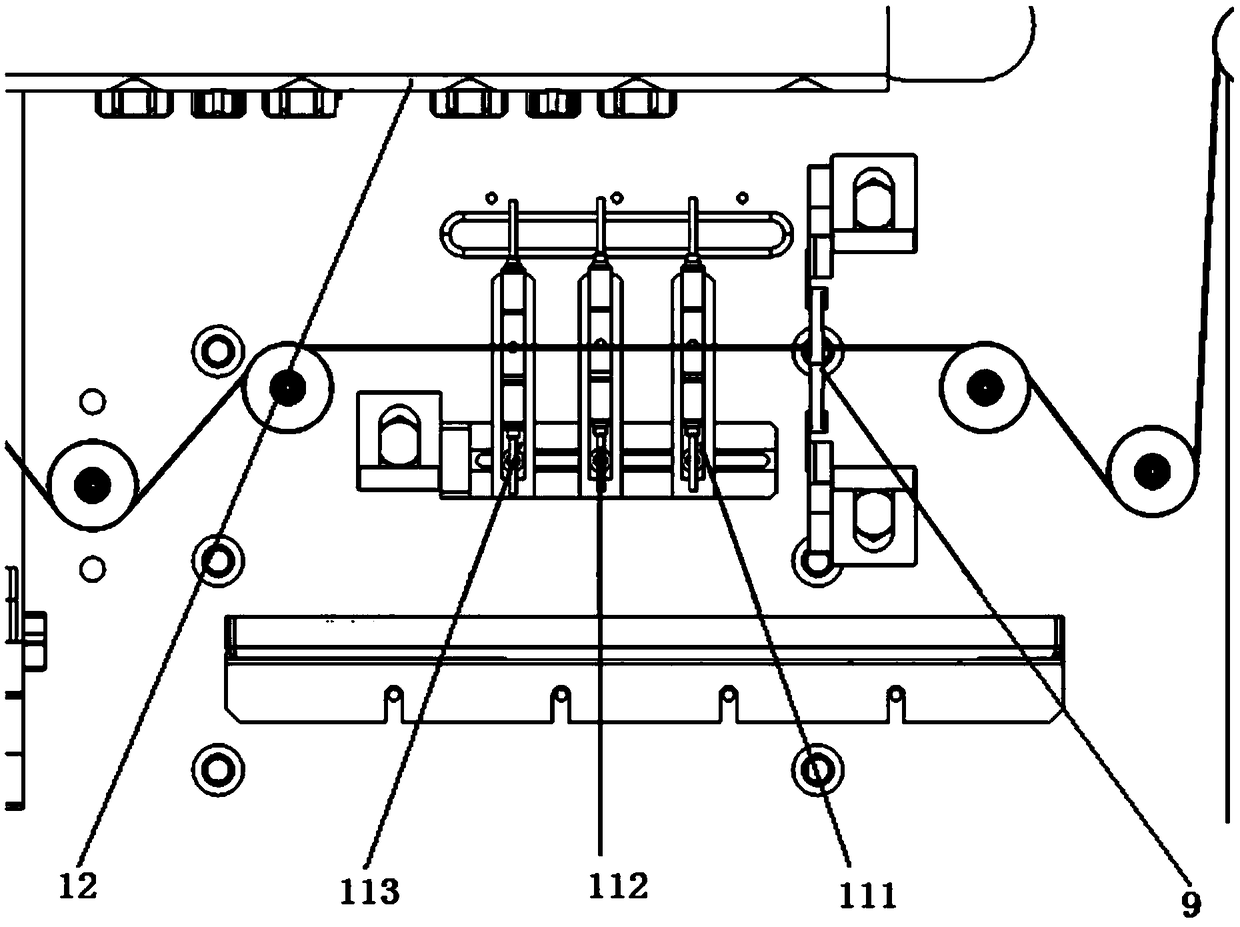

[0024] see Figure 1 to Figure 6 , the COF coil material automatic punching device in the present embodiment, comprises COF strip 13, frame 6, cabinet 4 and UPS uninterruptible power supply 5, is characterized in that: also comprises new material wheel 1, protective film recovery wheel 2, Waste recycling wheel 7, ratchet 8, punching mechanism 3 and a plurality of guide wheels; upper frame 6 and cabinet 4 are connected to form a device body, UPS uninterruptible power supply 5 forms a circuit connection with the electrical cabinet 41 inside the device body from the outside, The waste recovery wheel 7 and the new material wheel 1 are arranged on the top of the device body successively, and the protective film recovery wheel 2 is arranged on the bottom of the device body and corresponds to the new material wheel 1. The new material wheel 1, the protective film recovery wheel 2 and The rotating shaft in the middle part of the scrap recovery wheel 7 is connected with the servo motor...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com