Apparatus for automatically hollowing out label paper

A technology of label paper and power device, which is applied in the field of stamping equipment, can solve the problems of difficulty in realizing automaticity, balance, and low efficiency, and achieve the effect of novel structure, stable performance, and simple driving circuit

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] Attached below Figure 1-6 The present invention is described in further detail with specific embodiment:

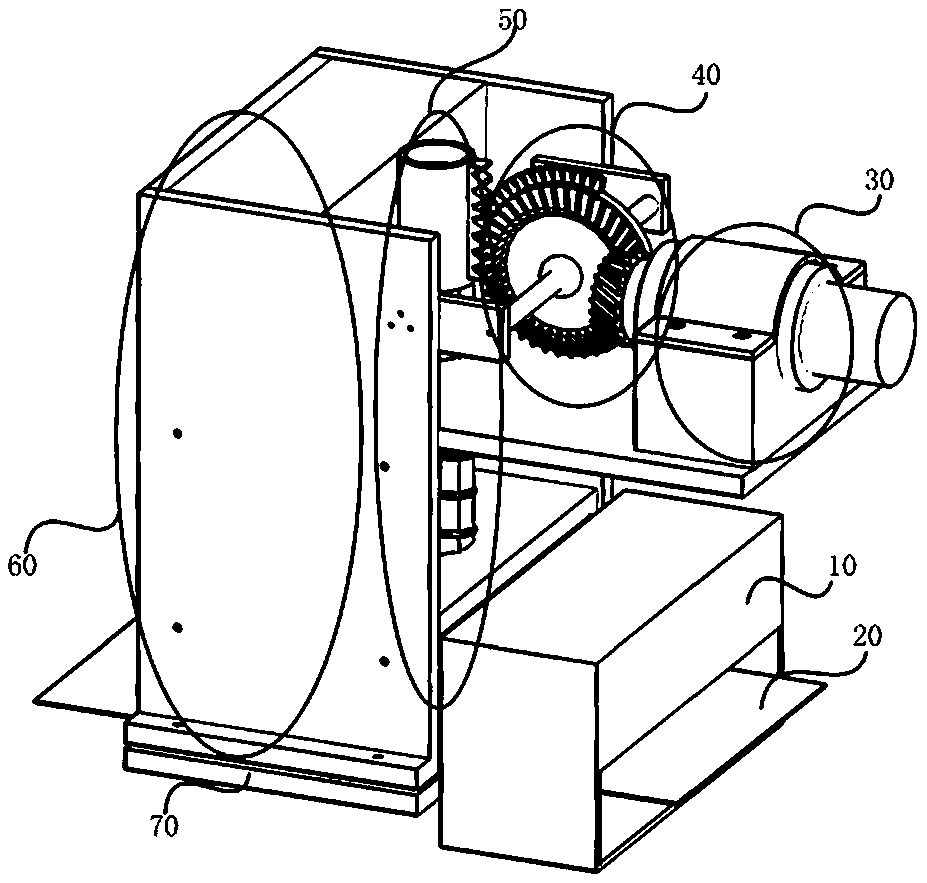

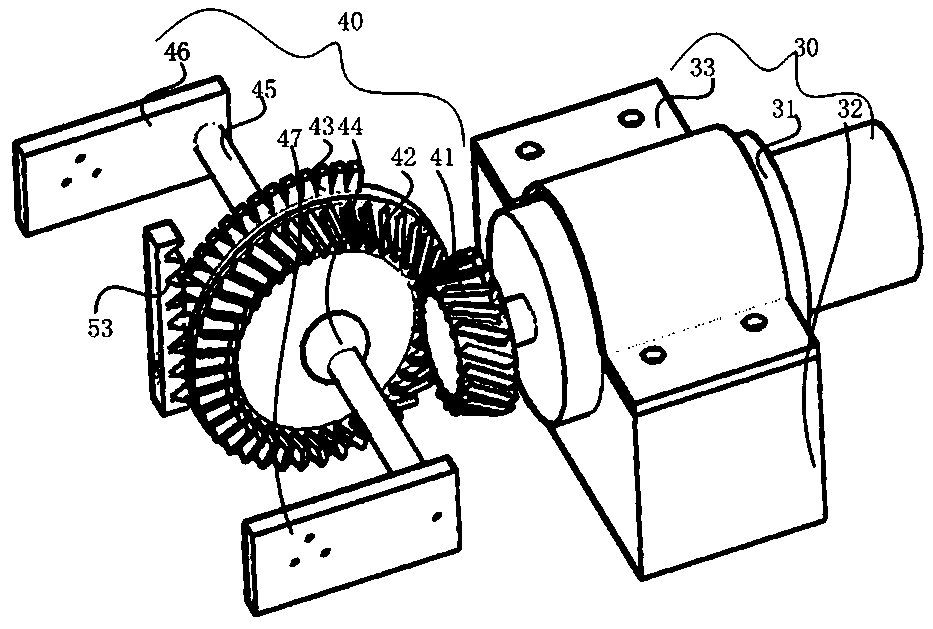

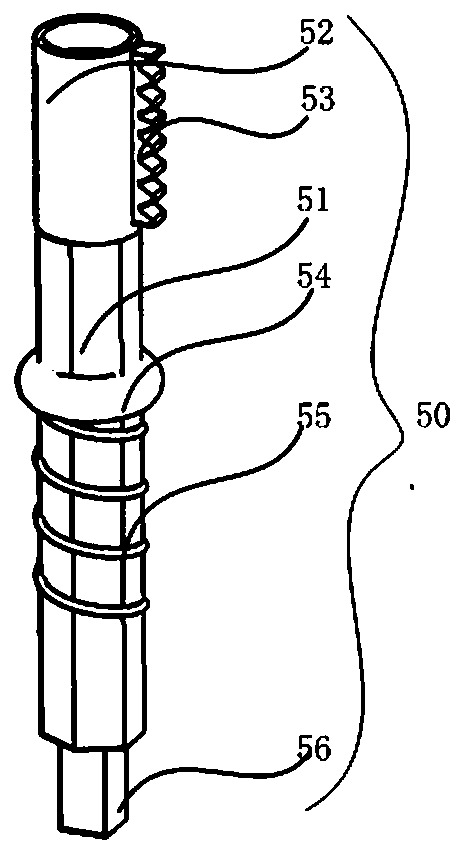

[0026] A device for automatically hollowing out label paper, including a transmission device 40, a power device 30, a mold core 50, and a frame body 60. The frame body 60 is composed of a side plate 61, a side plate 2 62, a back plate 63, and a fixing piece 64 , fixing part 2 65, lower mold base 70, limiting part 1 67, and limiting part 2 68, the side plate 2 62 and side plate 1 61 are vertically and vertically fixed on the left and right sides of the back plate 63 respectively by screws, so The first fixing part 64 is fixed on the bottom of the side plate one 61 by screws, the second fixing part 65 is fixed on the bottom of the side plate two 62 by screws, and the lower mold base 70 is fixed on the bottom of the first fixing part 67 and the second fixing part 65 by screws The rear end of the limiting part one 67 is horizontally and vertically arranged in the mid...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com