Slender diameter piston type piezoelectric straight line motor

A linear motor and piston-type technology, applied in piezoelectric effect/electrostrictive or magnetostrictive motors, piezoelectric devices/electrostrictive devices, generators/motors, etc., can solve the problem of low electromechanical energy conversion efficiency , Difficult to reduce the diameter of the driver structure, and the increase in the cost of the driver, etc., to achieve the effect of low power consumption, low cost, and stable output speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

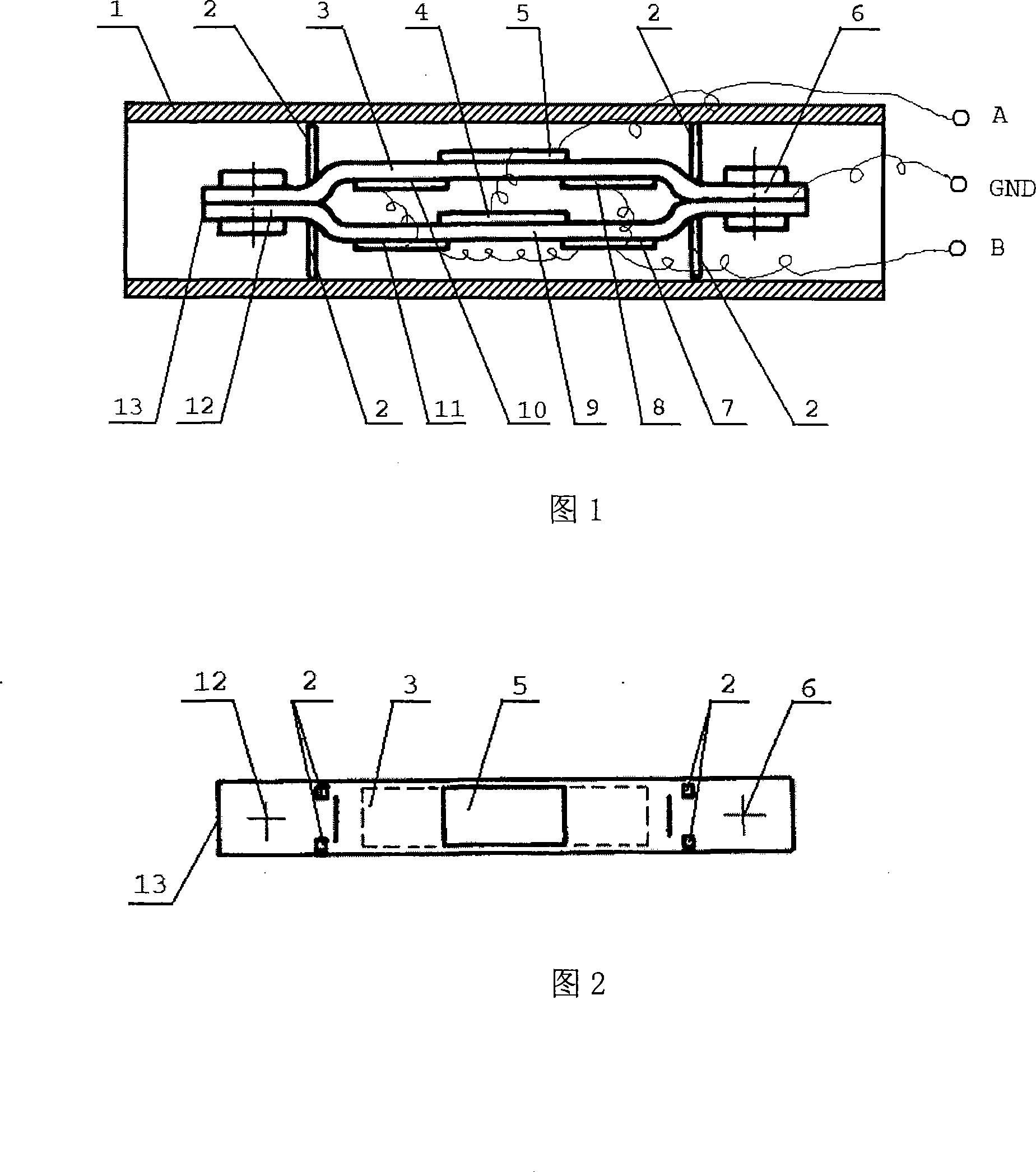

[0037] Referring to Fig. 1 and Fig. 2, the thin-diameter piston type piezoelectric linear motor includes a tubular stator 1 and a mover 13 placed in the tubular stator 1, and the mover 13 is composed of upper and lower layers of slender sheet-like vibrators 3, 9 and left and right End two coupling heads 6,12 are formed. The mover 13 is a left-right symmetrical structure. There are protrusions 2 symmetrically distributed above and below the mover 13 . The boss 2 is a thin elastic pin. The elongated sheet vibrator 3, 9 is composed of a narrow strip of elastic metal sheet and piezoelectric actuators 10, 5, 8, 11, 4, 7 pasted on its upper and lower surfaces. The piezoelectric actuator used here is a piezoelectric ceramic sheet uniformly coated with silver electrodes on the upper and lower sides and polarized along the thickness direction, so the piezoelectric actuator is referred to as a piezoelectric ceramic sheet hereinafter. When pasting, ensure that the polarization directi...

Embodiment 2

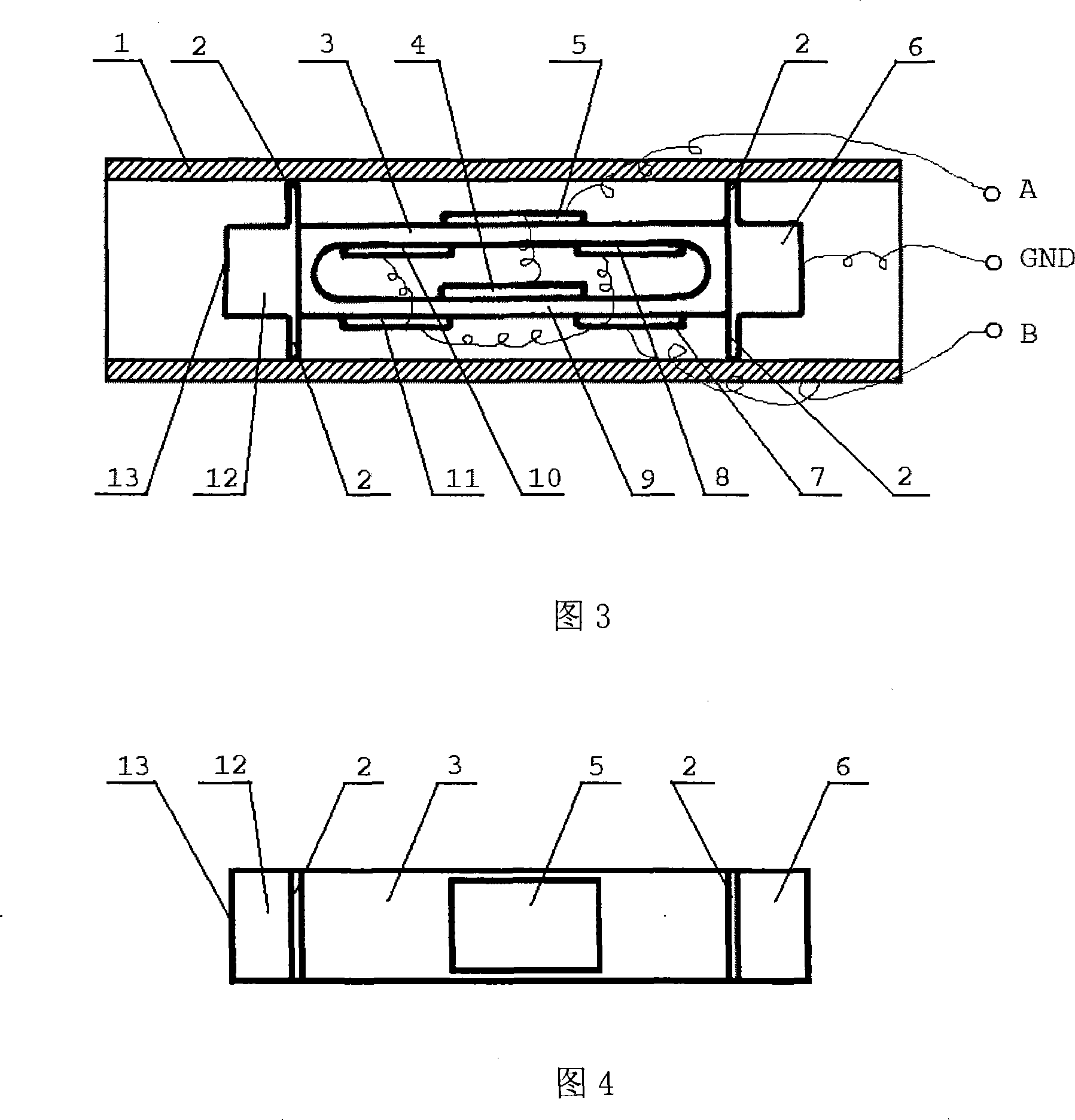

[0042] Referring to Fig. 3 and Fig. 4, the thin-diameter piston-type piezoelectric linear motor is basically the same as the above-mentioned embodiment. The difference is that the structure of the connecting head 6, 12 is: a whole block, in the middle of which two layers of elongated vibrator 3, 9 are processed, and the two ends maintain the original block three-dimensional rectangular body to form the connecting head 6, 12. The protrusions 2 at the upper and lower ends of the two elongated sheet vibrators 3 and 9 are thin elastic sheets.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com