Automatic punching mechanism for automobile die machining

An automobile mold and automatic technology, applied in the direction of metal processing equipment, perforating tools, manufacturing tools, etc., can solve problems such as personal accidents, low production efficiency, and unqualified product quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

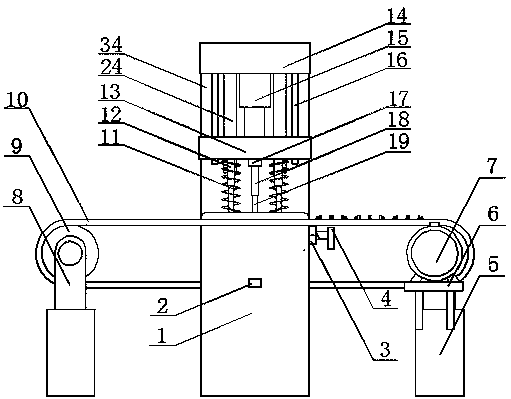

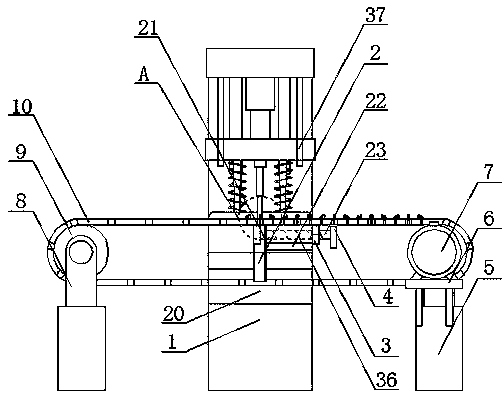

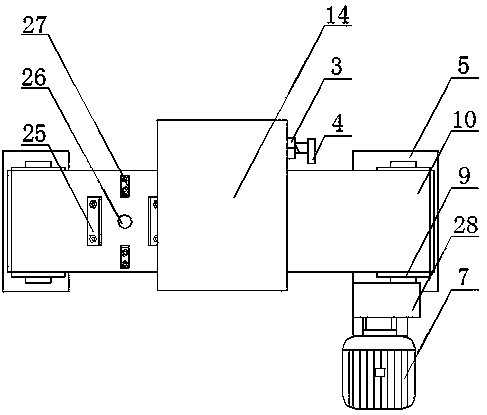

[0019] The following will clearly and completely describe the technical solutions in the embodiments of the present invention with reference to the accompanying drawings in the embodiments of the present invention. Obviously, the described embodiments are only some, not all, embodiments of the present invention.

[0020] refer to Figure 1-5, an automatic punching mechanism for automobile mold processing, including an operation table 1, and a discharge box 2 is provided through the side wall of one end of the operation table 1, and the waste materials punched can be slid into the waste material box. The first opening 20 is provided on the opposite side wall, and two bases 5 are fixed on both sides of the console 1, and the transmission belt 10 is stabilized. Rollers 9 are rotatably connected between the plates 8, and a transmission belt 10 is wound between the two rollers 9, and the transmission belt 10 passes through the first opening 20, and the lower end of the transmission...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com