Material packing method

A material and charging device technology, which is applied in the field of material packing, can solve the problems of complex process structure of the packing machine, large equipment footprint, high equipment manufacturing cost, etc., and achieve the effect of simple packaging method, less process and cost saving

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

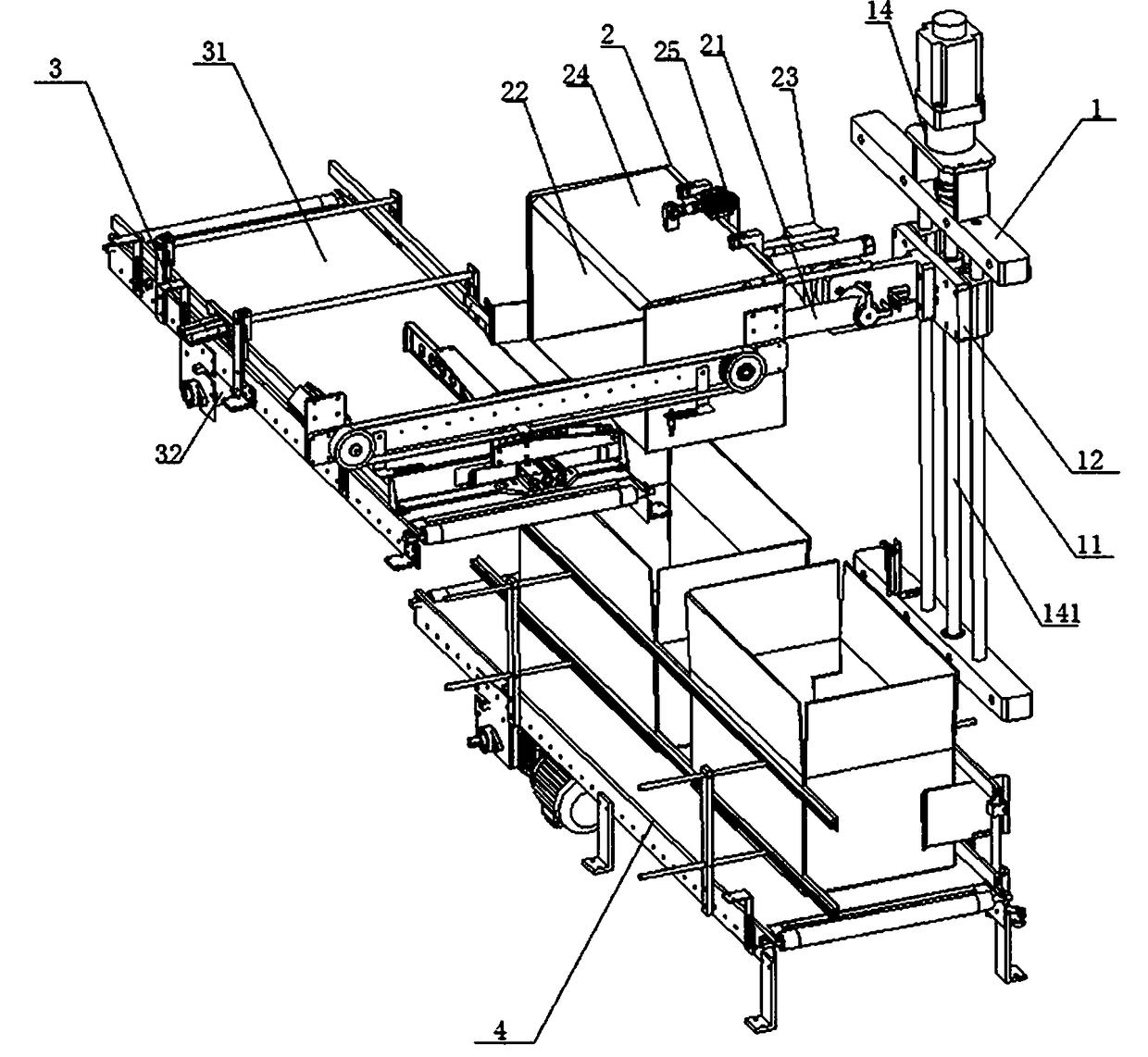

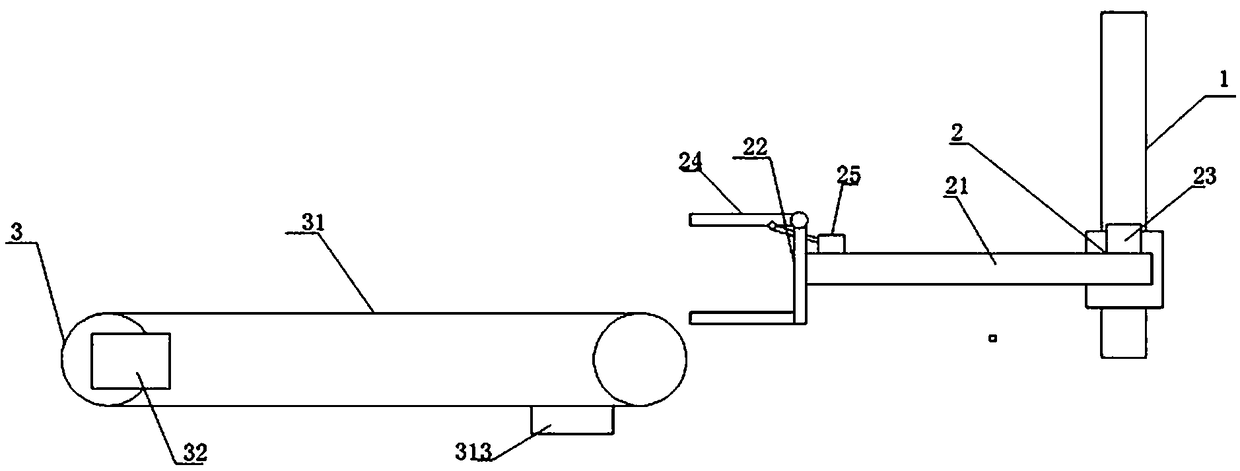

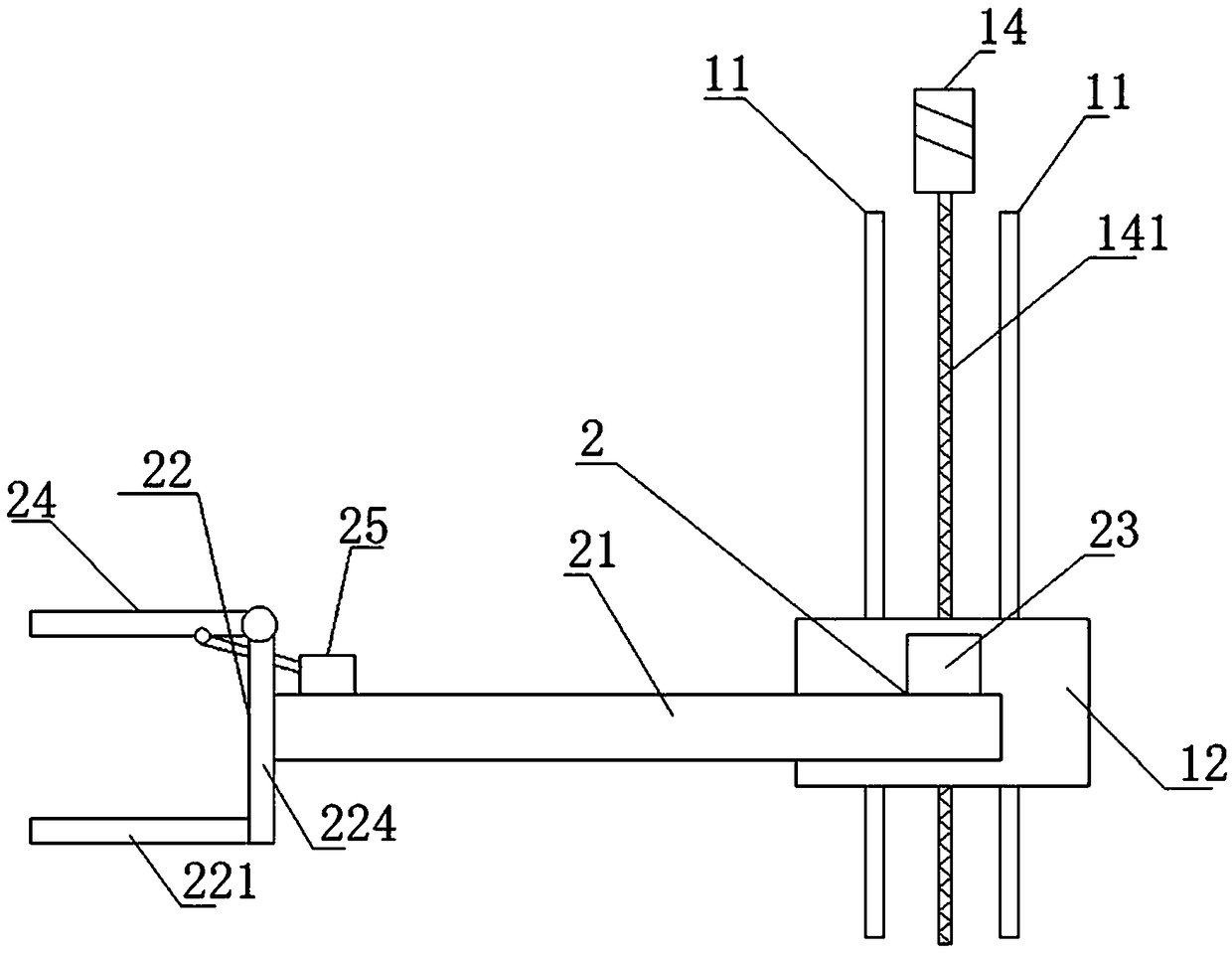

Image

Examples

Embodiment 1

[0063] As a preferred embodiment of the present invention, this embodiment discloses:

[0064] Material packing method, the material is transported to the material receiving station, after receiving a layer of material at the material receiving station, the height of the layer of material is lowered, and the next layer of material is transported to the top of the layer of material at the material receiving station, and carried out Material stacking: The set number of layers of materials are stacked on the receiving station, the materials are clamped and turned 90°, and the turned materials are put into the packing box.

Embodiment 2

[0066] As another preferred embodiment of the present invention, this embodiment discloses:

[0067] Material packing method, the material is transported to the material receiving station, after receiving a layer of material at the material receiving station, the height of the layer of material is lowered, and the next layer of material is transported to the top of the layer of material at the material receiving station, and carried out Material stacking: The set number of layers of materials are stacked on the receiving station, the materials are clamped and turned 90°, and the turned materials are put into the packing box;

[0068] In this embodiment, the receipt of a layer of material by the material receiving station specifically refers to: a package of material received by the material receiving station is a layer of material.

[0069] In this embodiment, the receipt of a layer of material by the material receiving station can also be: the material receiving station recei...

Embodiment 3

[0071] As another preferred embodiment of the present invention, this embodiment discloses:

[0072] Material packing method, the material is transported to the material receiving station, after receiving a layer of material at the material receiving station, the height of the layer of material is lowered, and the next layer of material is transported to the top of the layer of material at the material receiving station, and carried out Material stacking: The set number of layers of materials are stacked on the receiving station, the materials are clamped and turned 90°, and the turned materials are put into the packing box;

[0073] In this embodiment, the receipt of a layer of material at the receiving station specifically refers to: receiving a pack of materials at the receiving station is a layer of material;

[0074] In this embodiment, the receipt of a layer of material by the material receiving station can also be: the material receiving station receives multiple packag...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com