Automatic uniform drilling device for birdcage top frame

A drilling equipment and top frame technology, which is applied in the field of automatic uniform drilling equipment for the top frame of bird cages, can solve problems such as the inability to ensure the consistency of adjacent holes, and achieve the effect of preventing falling everywhere

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

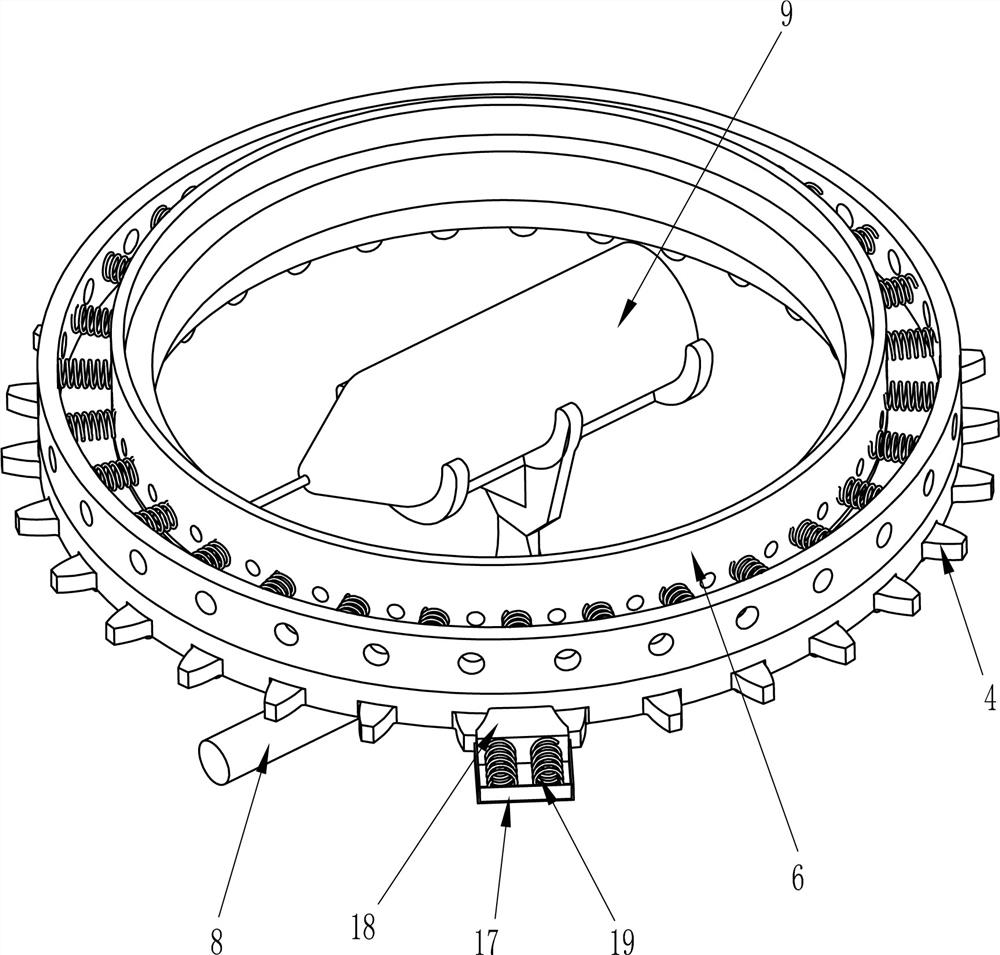

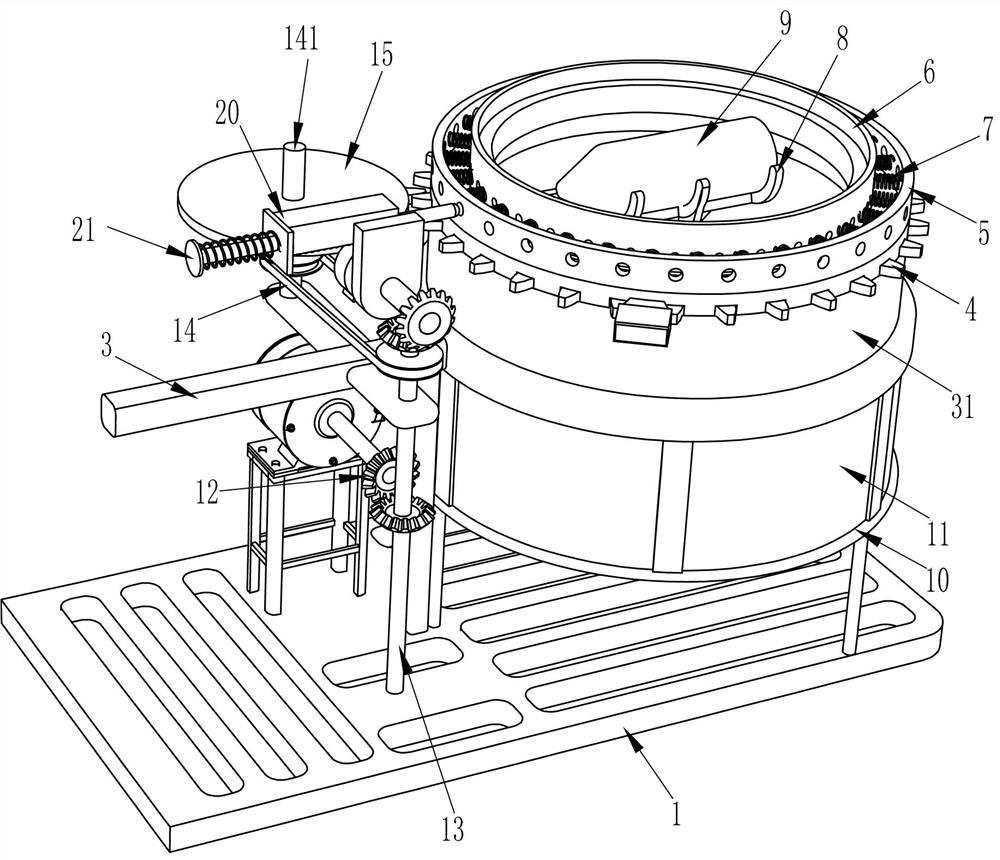

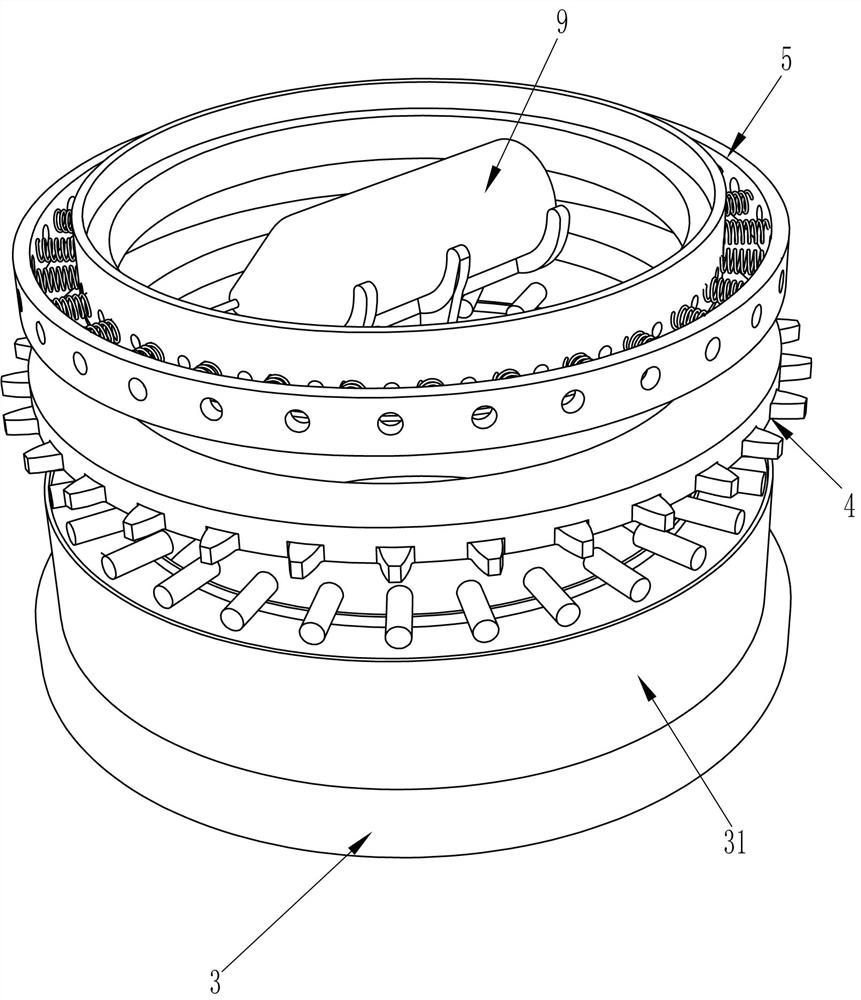

[0022] A kind of birdcage top frame automatic uniform drilling equipment, such as Figure 1-5 As shown, it includes a frame 1, a motor 2, a first support frame 3, a connecting ring 31, a ring rack 4, a second ring 6, a first ring 5, a first spring 7, a second support frame 8, Electric drill 9, third support frame 10, waste material frame 11, first straight bevel gear 12, first rotating shaft 13, transmission device 14, second rotating shaft 141, single tooth gear 15, limit rod 16, fixing mechanism and drilling Mechanism, the left side of the front part of the inner bottom wall of the frame 1 is rotationally connected with the first rotating shaft 13, and the left side of the rear part of the inner bottom wall of the frame 1 is equipped with a motor 2, and the output shaft of the motor 2 is connected with the middle part of the first rotating shaft 13 There is a first straight bevel gear 12, two first straight bevel gears 12 are meshed, a first support frame 3 is installed in t...

Embodiment 2

[0025] On the basis of Example 1, such as figure 2 , 4 with Figure 5 As shown, the fixing mechanism includes a first guide sleeve 17, a wedge block 18 and a second spring 19. The first guide sleeve 17 is connected to the lower end of the limit rod 16 on the front side, and the front and rear sides of the inner wall of the first guide sleeve 17 are connected to the second spring. Two springs 19, a wedge block 18 is connected to the rear end of the first guide sleeve 17, and the wedge block 18 is in contact with the ring rack 4.

[0026]When people drilled the top frame of the birdcage, the top frame of the birdcage was placed in the second ring 6, the motor 2 and the electric drill 9 were started, and when the single-toothed gear 15 meshed with the ring rack 4, the ring rack 4 Rotate, the tooth of ring rack 4 is positioned between the top wall and the bottom wall of wedge block 18 and contacts with it, when single-tooth gear 15 and ring rack 4 are not meshed, the top wall o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com