Manual puncher

A manual punching and punching machine technology, applied in the field of punching machines, can solve the problems of high automatic production cost, high production cost, and inability to start automatic production, and achieve the effects of convenient implementation, low cost, and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

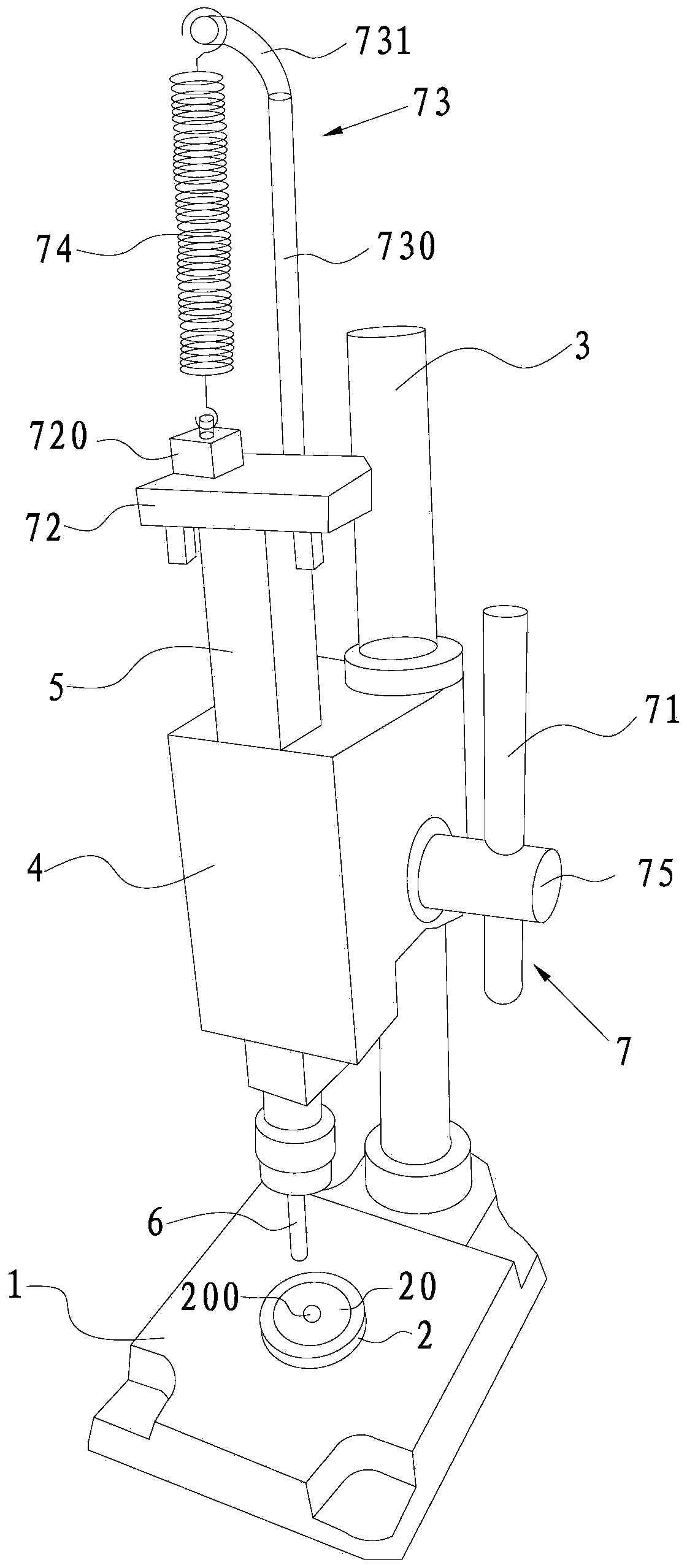

[0017] Such as figure 1 and figure 2 As shown, the manual punching machine provided in this embodiment includes a bottom mold 2 arranged on the work surface 1, a positioning column 3 vertically arranged on the work surface 1, sleeved on the positioning column 3 and positioned on the bottom mold 2 The upper positioning module 4, the mandrel 5 parallel to the positioning column 3 and arranged on the positioning module 4, the hole needle 6 arranged at the lower end of the mandrel 5, and the adjustment mandrel 5 moving up and down along its own length direction The adjustment mechanism 7.

[0018] In this example, the above-mentioned bottom mold 2 has a positioning groove 20 for placing parts to be processed, the hole needle 6 is located directly above the positioning groove 20 , and a hole 200 matching the hole needle 6 is provided at the bottom of the positioning groove 20 .

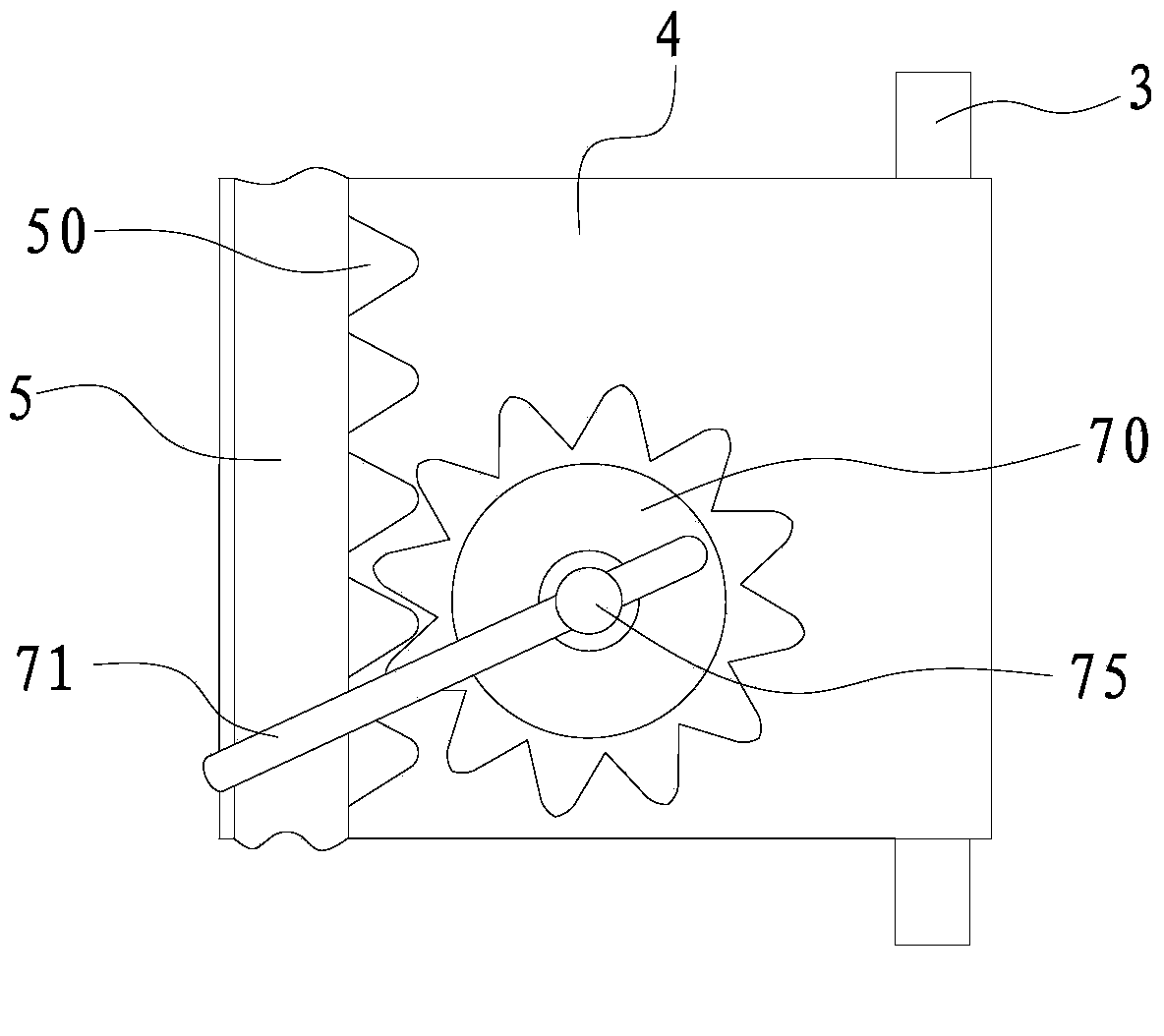

[0019] At the same time, a rack 50 is provided on the side of the mandrel 5 relative to the position...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com