Automatic punching and placing machine

An automatic punching and placing technology, applied in metal processing and other directions, can solve the problems of increasing R&D and manufacturing costs, increasing product defect rate, increasing turnover cycle, etc., achieving the effect of ingenious design, lowering production costs, and reducing turnover process.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

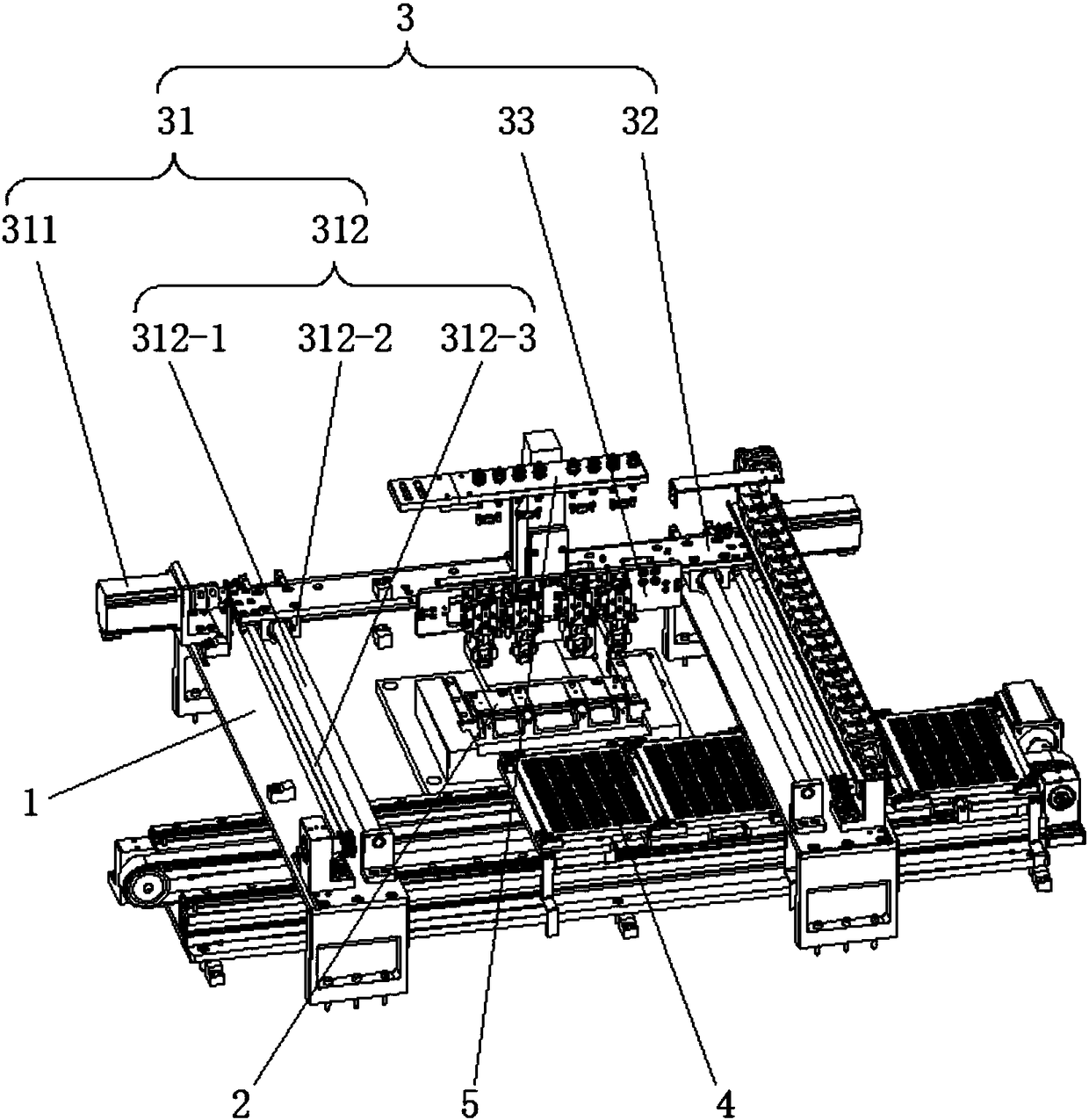

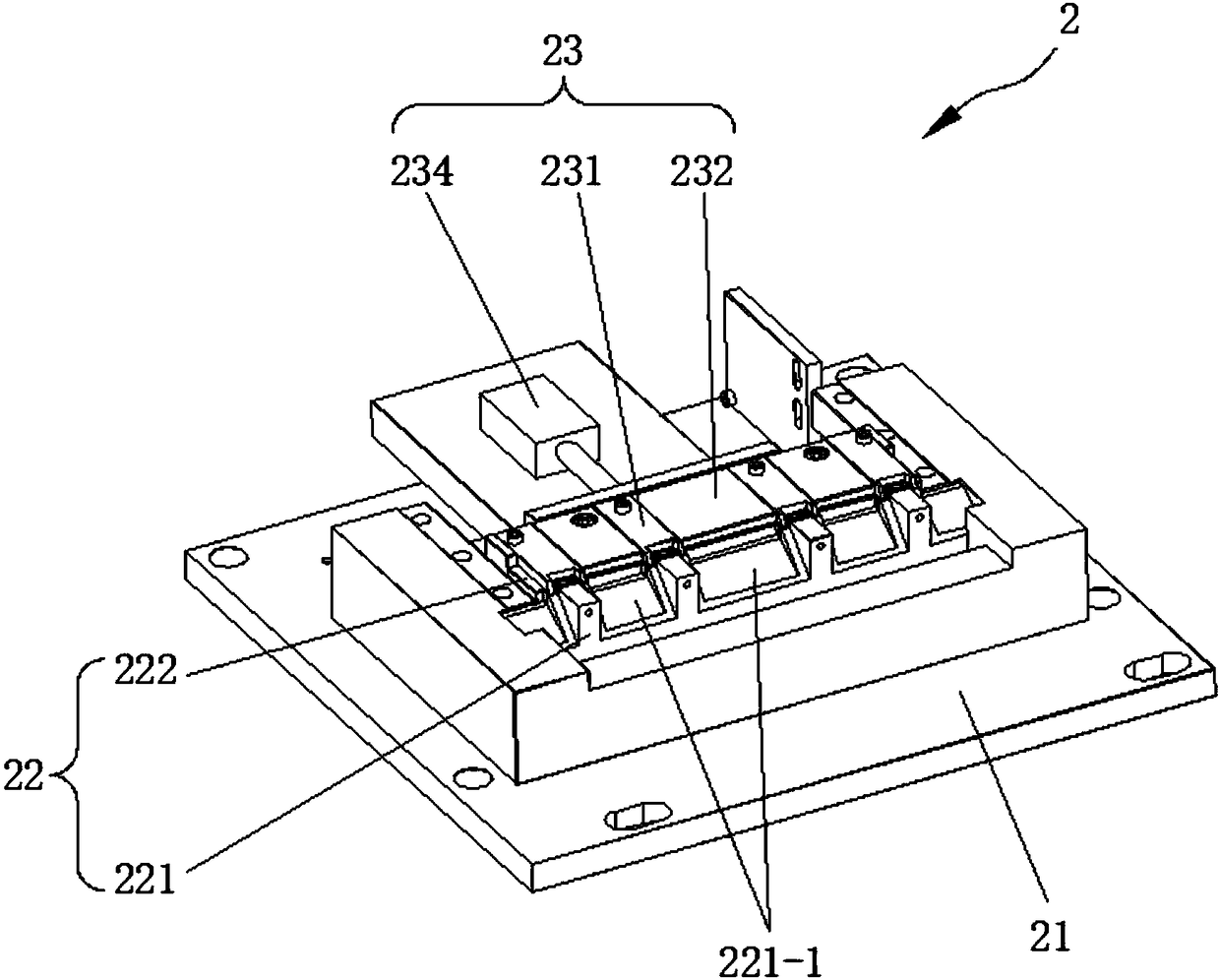

[0027] See Figure 1 to Figure 5 , the present invention has a frame 1; the frame 1 is provided with a punching mechanism 2, a transfer mechanism 3 and a pendulum mechanism 4; the punching mechanism 2 includes a substrate 21, and the substrate 21 is fixedly connected to the frame 1; The substrate 21 is provided with a clamping assembly 22 that can clamp the workpiece, and a punching assembly 23 that can punch the workpiece; the clamping assembly 22 is provided with a plurality of clamping positions; the punching The component 23 is provided with a punching head 231 corresponding to the clamping position one by one;

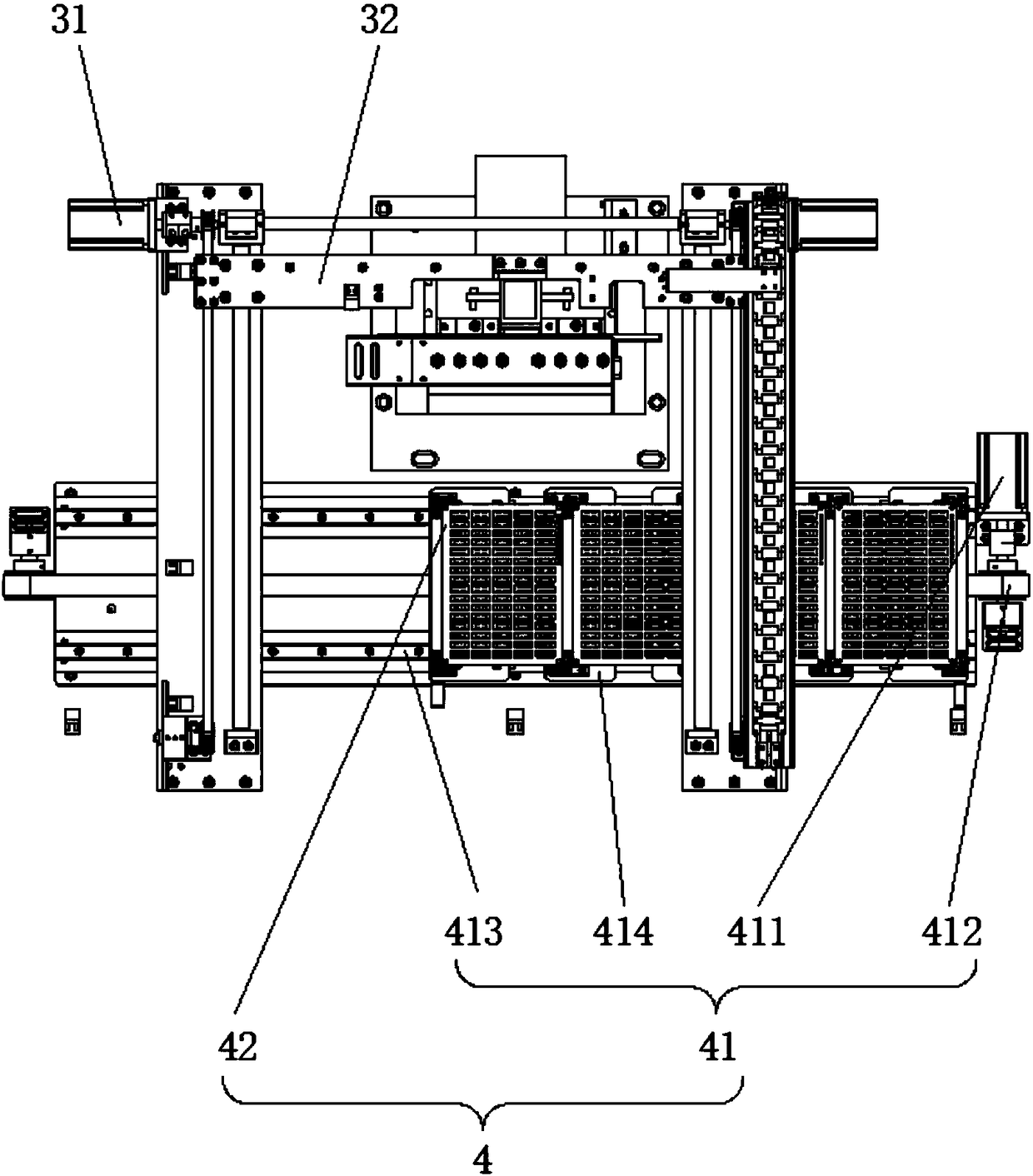

[0028] The transfer mechanism 3 includes a support frame 32 fixedly connected to the sliding device 31; the support frame 32 is provided with a plurality of clamping assemblies 33 corresponding to the clamping positions one by one and used for clamping the workpiece;

[0029] The pendulum mechanism 4 includes a plurality of pendulum plates 42 arranged on the tran...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com