Turnover tool vehicle for processing motor shell

A technology of electric motors and turnover workers, applied in the field of mechanical processing tooling, can solve the problems of manual operations, affecting production efficiency, scalding trays, etc., and achieve the effects of flexible movement, improved turnover efficiency, and smooth sliding

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] Below in conjunction with accompanying drawing and specific embodiment the present invention is described in further detail:

[0027] The invention discloses a motor casing processing turnover tooling vehicle, which is used in the motor processing process. The turnover tooling vehicle can transport the motor casing to be hot-packed into an electromagnetic heater, and further transfer it after the heating is completed. to the hot loading station. The following are specific examples:

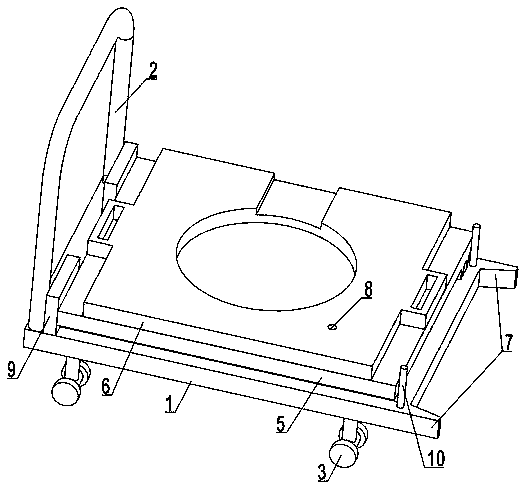

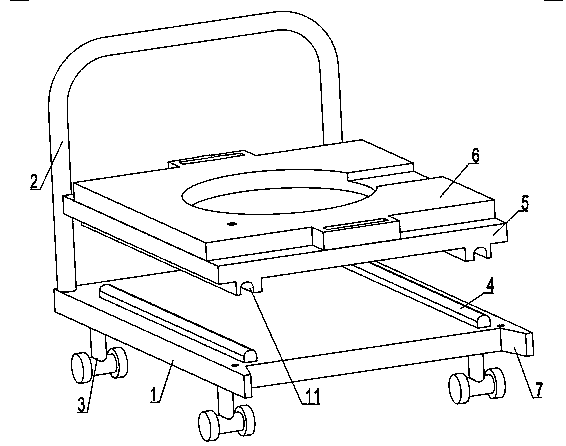

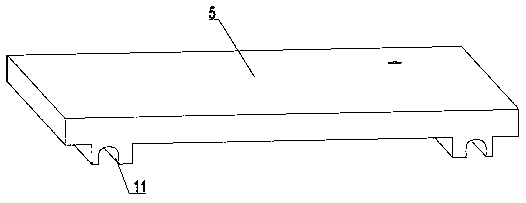

[0028] The motor casing processing turnover tooling vehicle of the present invention, such as figure 1 , figure 2 As shown, a chassis 1 is provided, a slide rail 4 is provided on the upper surface of the chassis 1 , and a roller 3 is provided on the lower surface of the chassis 1 . The upper end surface of the chassis 1 is also provided with a pallet assembly for carrying and transporting workpieces. The accompanying board assembly can slide along the slide rail 4 . The accompanying p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com