Novel technology for synthesizing acetochlor intermediate chloroethyl methyl ether

A technology of chloromethyl ethyl ether and synthesis process, which is applied in the preparation of organic compounds, chemical instruments and methods, organic chemistry, etc., can solve the problems of low etherification rate, cumbersome process, low utilization rate of hydrochloric acid, etc., and achieve improvement Improve quality, simplify process steps, and reduce the effect of material turnover process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

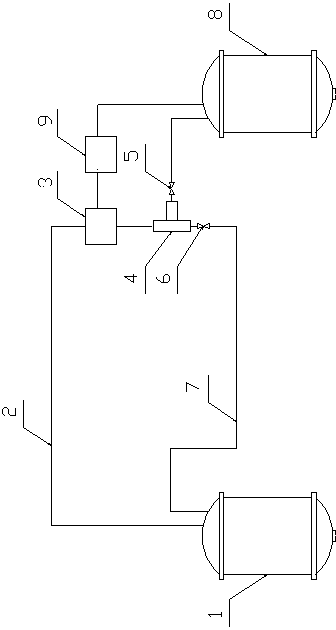

[0015] Aiming at the problems of cumbersome steps in the existing synthesis process, low utilization rate of raw materials and low etherification rate, the present invention provides a new synthesis process of acetochlor intermediate chloromethyl ethyl ether. The new synthesis process comprises the following steps:

[0016] (1) Put the ammonium chloride into the ether distillation still containing the etherified base acid, mix well, add concentrated sulfuric acid dropwise at a uniform speed and stir, and the ammonium chloride will generate hydrogen chloride gas under the action of concentrated sulfuric acid;

[0017] (2) After drying the hydrogen chloride gas obtained in step (1) through concentrated sulfuric acid, it is passed into the etherification reaction kettle containing paraformaldehyde and ethanol, and the temperature is kept at about 60°C. When there is a large amount of The reaction ends when hydrogen chloride gas that has not participated in the reaction comes out. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com