Double-station continuous stamping die for sheet metal parts

A stamping die, double-station technology, applied in the direction of manufacturing tools, other manufacturing equipment/tools, etc., can solve the problems of inability to realize multi-station and continuous processing, and achieve the effect of improving efficiency and reducing costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments.

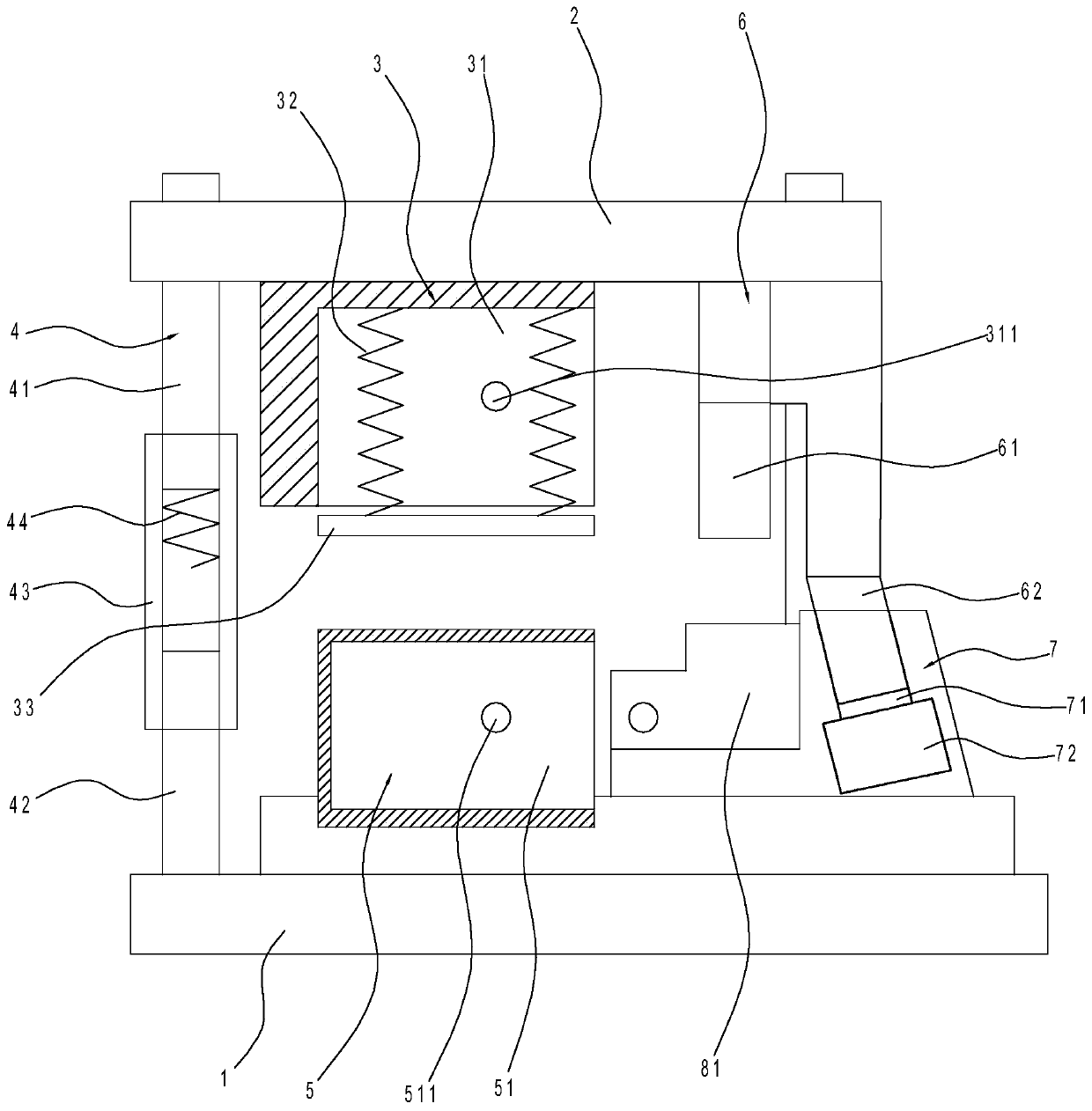

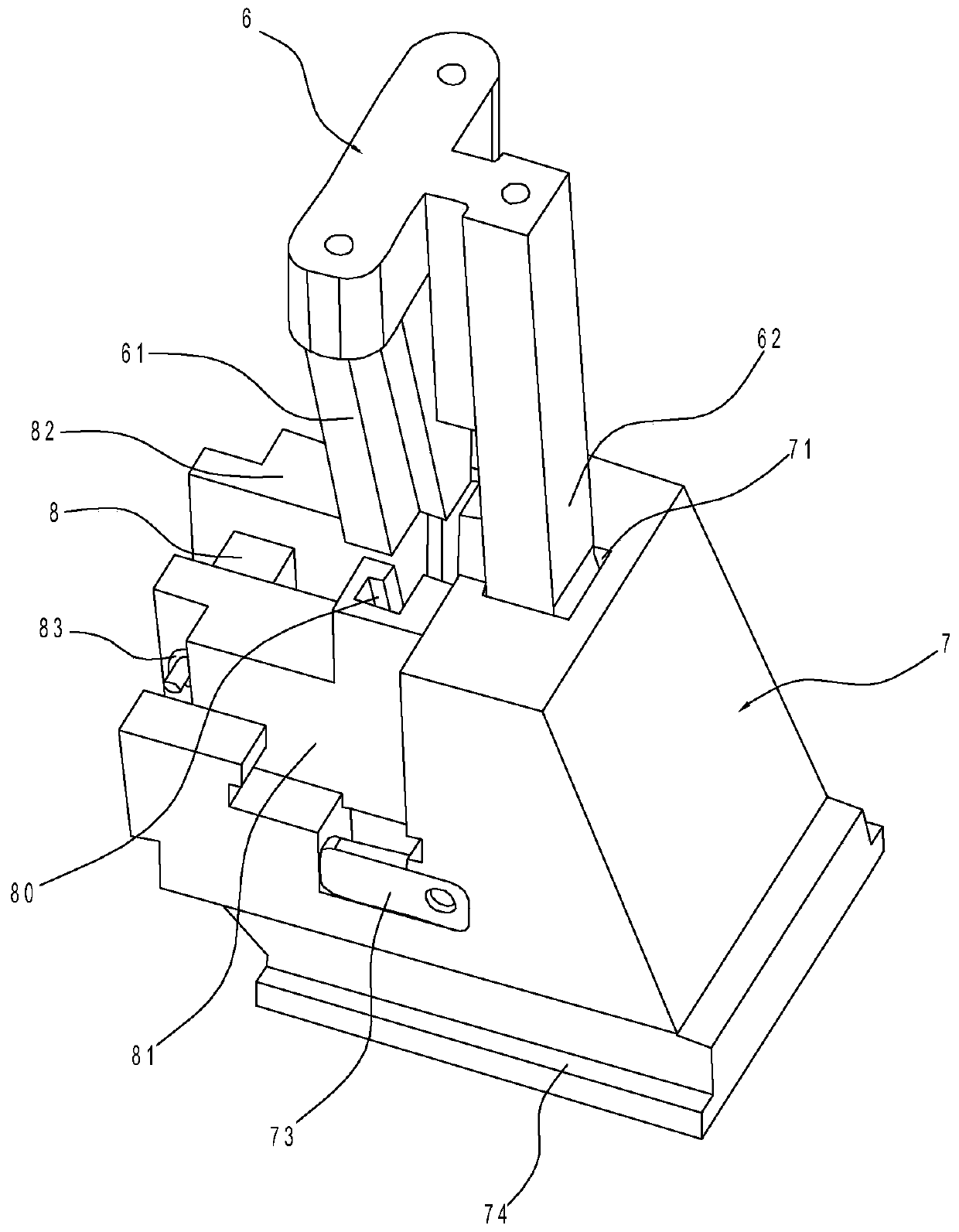

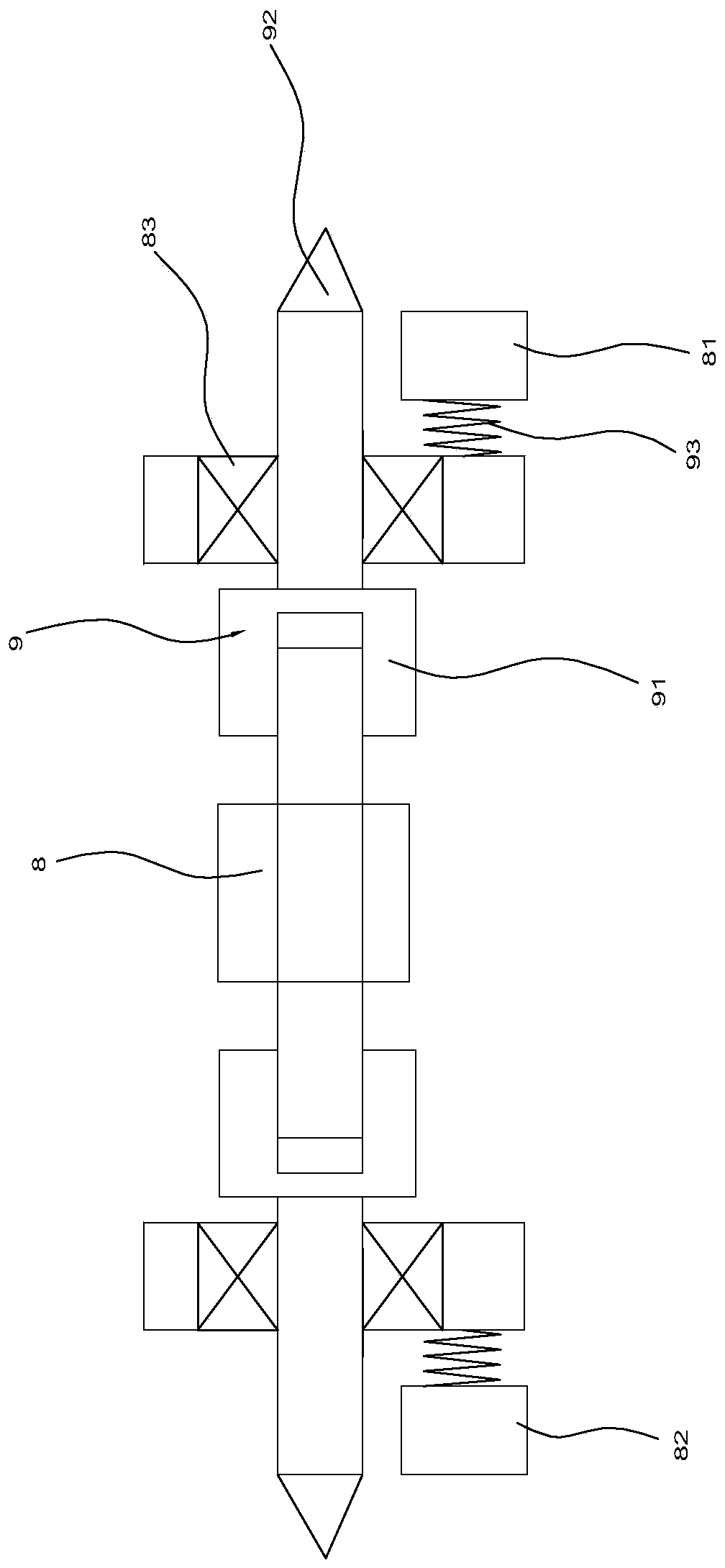

[0020] Such as Figures 1 to 6 As shown, the double-station continuous stamping die for sheet metal parts in this implementation includes a base plate 1, a guide post 4, an upper template 2, an upper mold 3, a lower mold 5, a pressure plate 33, a compression spring 32, a linkage 6, a slide Seat 7, hollow motor 8, front slide block 81, back slide block 82, back-moving spring 93, support bearing 83.

[0021] Wherein, the guide pillar 4 is arranged on the bottom plate 1, the upper mold 2 is arranged on the guide pillar 4, the upper mold 3 is arranged on the upper template 2, the lower mold 5 is arranged on the bottom plate 1, and the upper mold 3 is formed with The cavity 31 opening downwards, the right side of the cavity 31 communicates with the outside, the bottom of the cavity 31 is connected with a compression spring 32, and the lower end of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com