Processing method of communication equipment aluminum plate

A processing method and technology of communication equipment, applied in the direction of metal processing, metal processing equipment, metal processing machinery parts, etc., can solve the problems of poor heat dissipation effect of aluminum plate, communication signal influence, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0044] A processing method of an aluminum plate for communication equipment, comprising the following steps:

[0045] S1. Select the appropriate size of aluminum plate raw material for cutting, grind the aluminum plate raw material after cutting, and remove the burrs and stubble on the surface of the incision;

[0046] S2. Place the aluminum plate to be processed on the automatic processing machine, bend and open the aluminum plate, and use the demoulding device to assist the mold release of the processed aluminum plate;

[0047] S3. Collect the processed aluminum plates uniformly, detect the hole diameter and bending angle of the processed aluminum plates, and place the composite standard aluminum plates in a centralized manner.

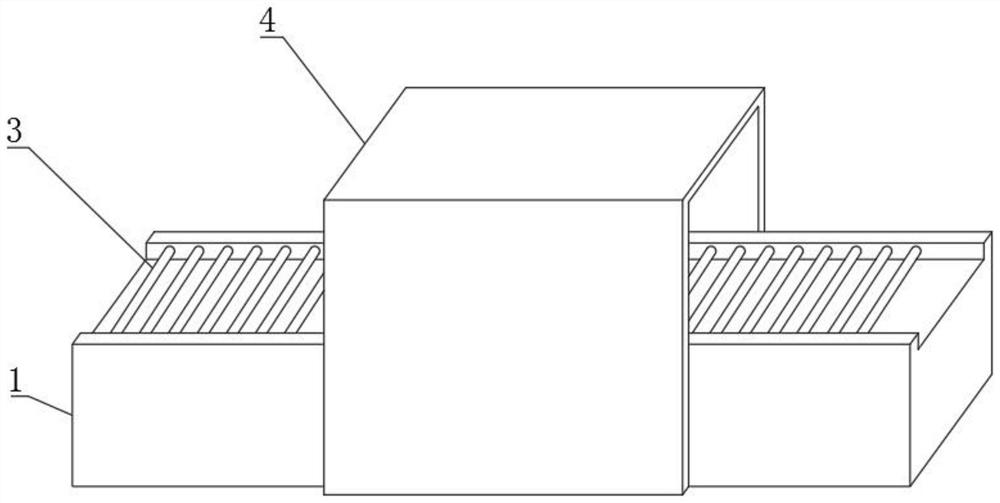

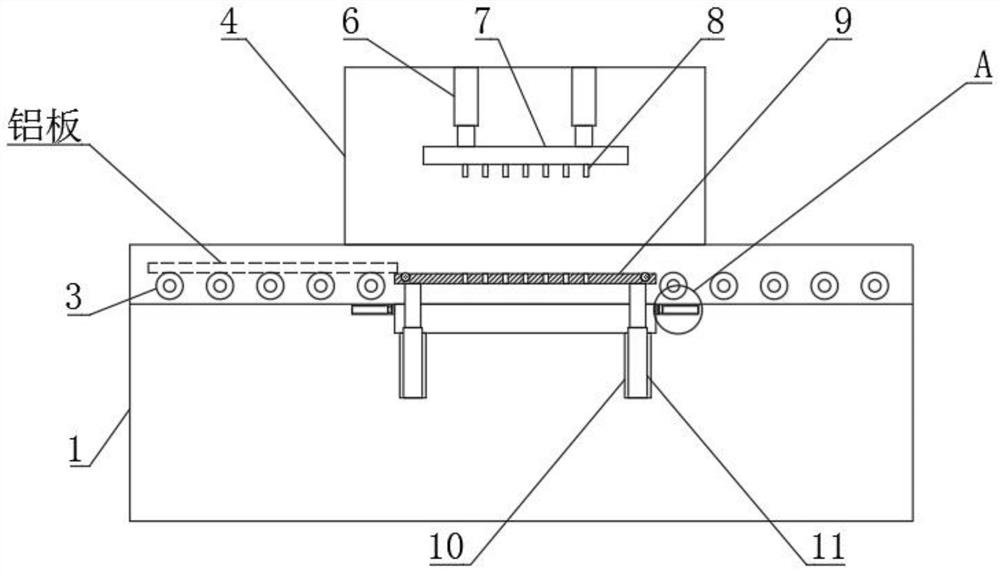

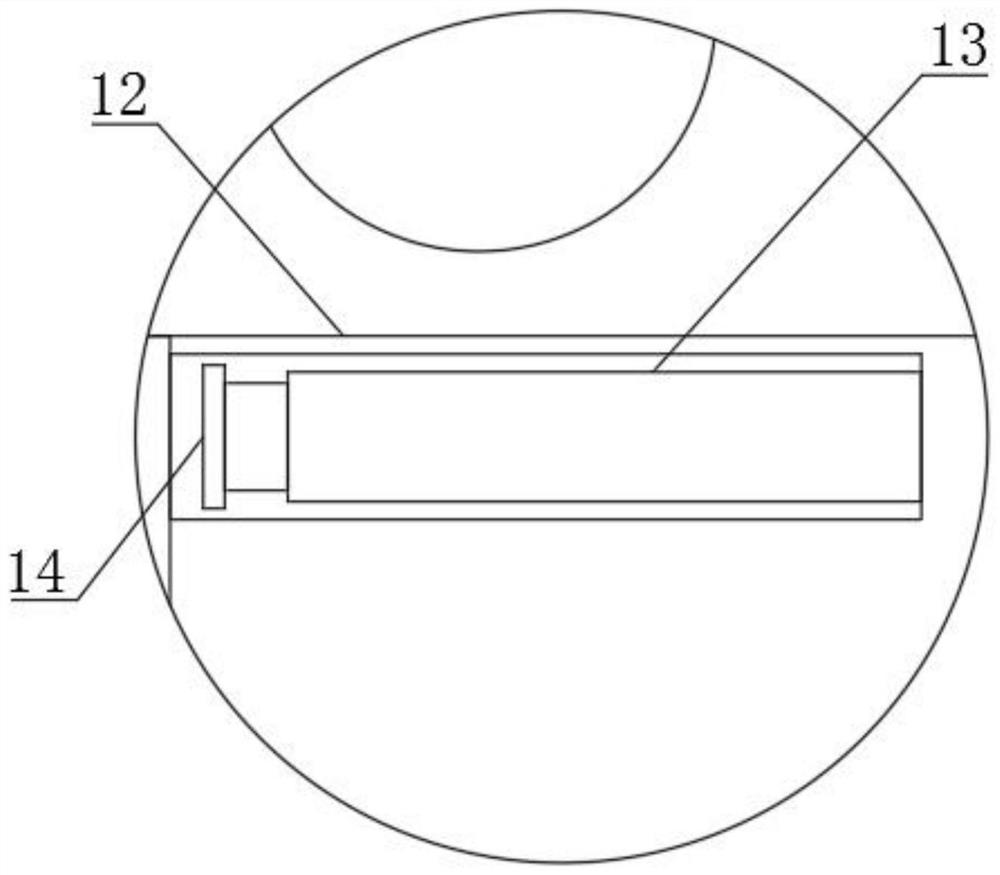

[0048] see Figure 1-5 , the automatic processing machine includes a conveyor 1, the inner walls of the conveyor 1 are rollingly connected with a plurality of evenly distributed transmission shafts 3, the upper end of the conveyor 1 is fixedly conn...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com