Special manufacturing production line for automotive web plate

A production line and web technology, which is applied in the field of stamping processing and forming, can solve the problems of inconvenient transportation, space occupation, and long length of the web, and achieve the effects of high degree of stamping automation, adjustable position, and scientific design

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The technical solutions of the present invention will be described in further detail below through specific implementation methods.

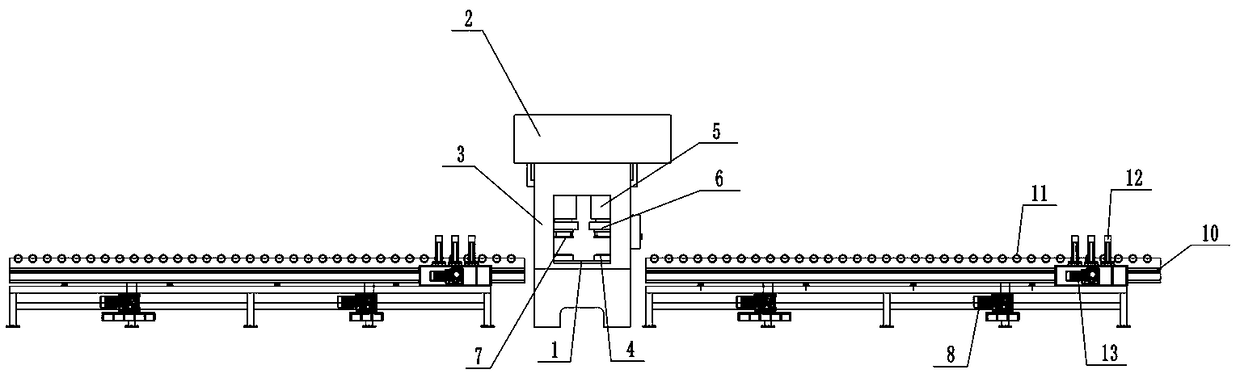

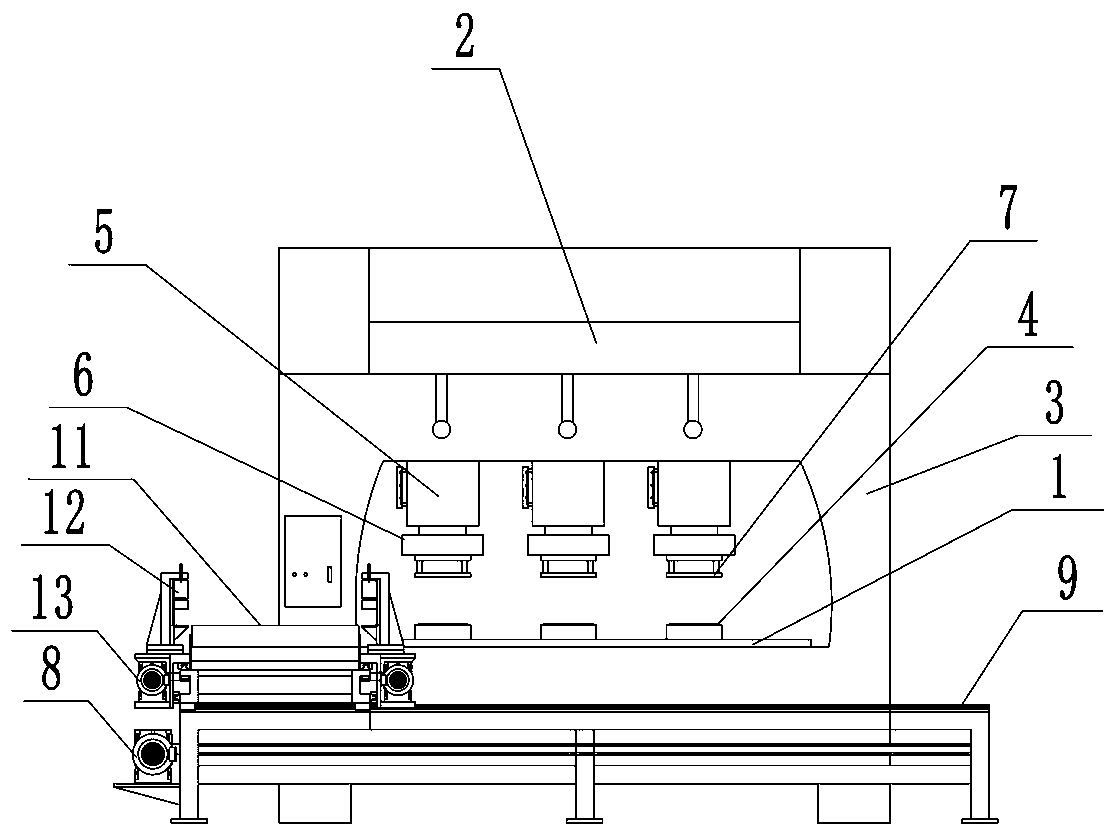

[0019] Such as figure 1 and figure 2 As shown, a special processing production line for automobile webs includes a punch main machine, a feeding mechanism, a material receiving mechanism and a control mechanism. The punch machine, the feeding mechanism and the material receiving mechanism are respectively connected to the control mechanism. The main machine of the punching machine includes a punching machine body, hydraulic punching equipment and a punching work platform 1. The punching machine body is a closed frame structure formed by a beam 2, two side frames 3 and a base. The punching work platform 1 is installed on On the base, a number of stamping lower molds 4 are installed on the stamping work platform 1, and a mold material collection device is provided directly below the stamping work platform 1 to collect the mold materials d...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com