Steel pipe cutting and punching machine

A technology of punching machine and steel pipe, which is applied in the field of steel pipe processing, can solve the problems that automatic punching and cutting cannot be realized, and achieve the effect of convenient maintenance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

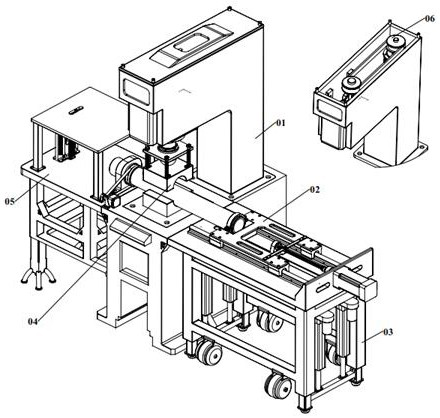

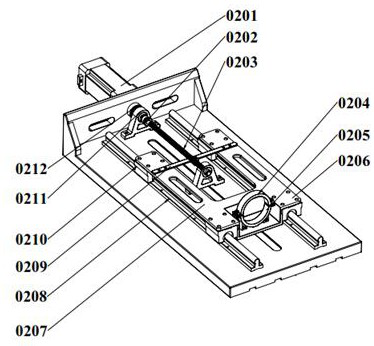

[0032] Example: such as figure 1 , figure 2 , image 3 , Figure 4 , Figure 5 , Figure 6 , Figure 7 , Figure 8 , Figure 9 , Figure 10 A steel pipe cutting and punching machine is shown. The shell system 1 is the base device, the shell system 1 is the installation platform of the mobile system 3 and the main system 5, the mobile system 3 is the installation platform of the propulsion system 2, the shell system 1 is the installation platform of the drive system 6, and the stamping system 4 is the drive system 6 installation platforms;

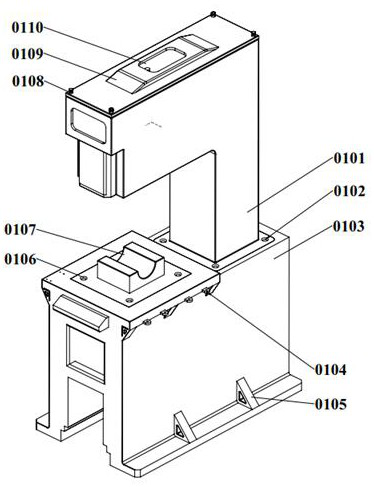

[0033] The concrete structure of shell system 1 is as follows figure 2 As shown, the lower shell 103 is placed on the ground, the rib plate 105 is fixedly installed on the lower shell 103, the lower shell 103 is provided with connecting ears 104, the connecting plate 106 is fixedly installed on the lower shell 103, and the lower clamping block 107 is fixedly installed on the connecting On the plate 106, the connecting plate 102...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com