Large scale integrated (LSI) circuit swash runner die with drawer type structure

A large-scale integrated circuit and drawer-type structure technology, which is applied in the direction of forming tools, manufacturing tools, metal processing equipment, etc., can solve the problems of low safety and easy injury of operators' hands by the flushing channel mold, so as to increase safety sexual effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

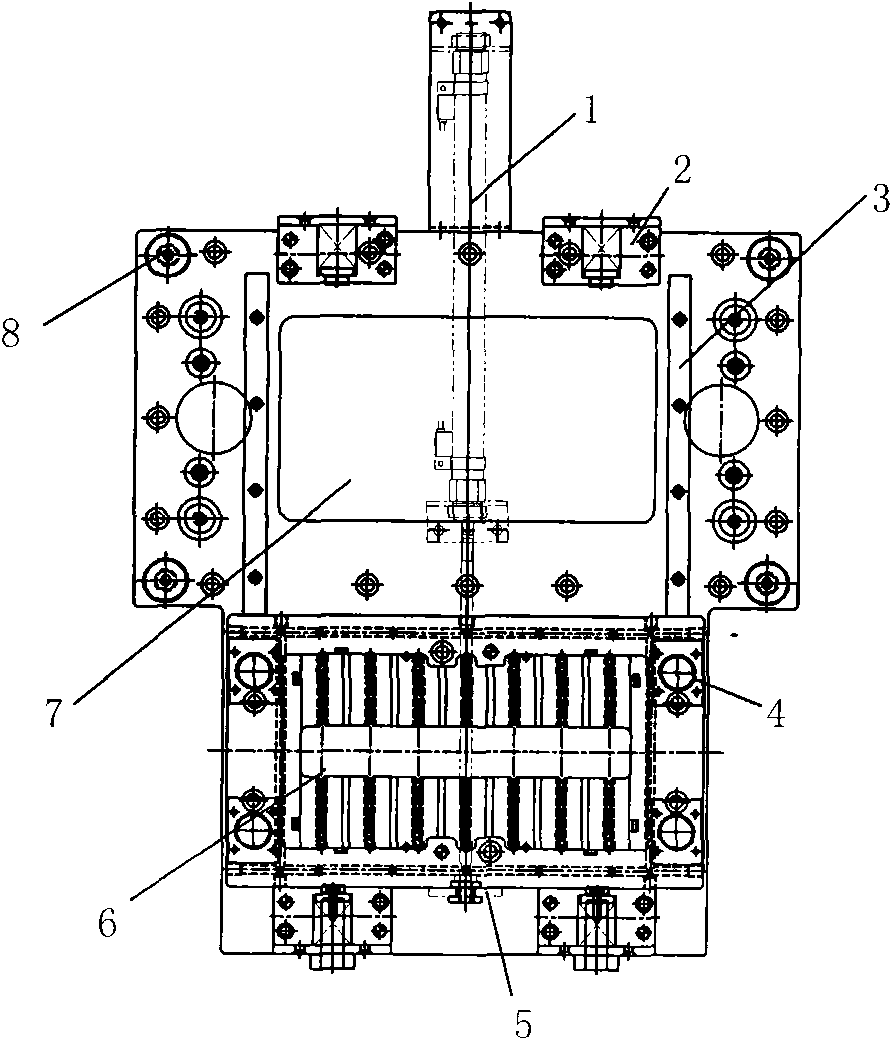

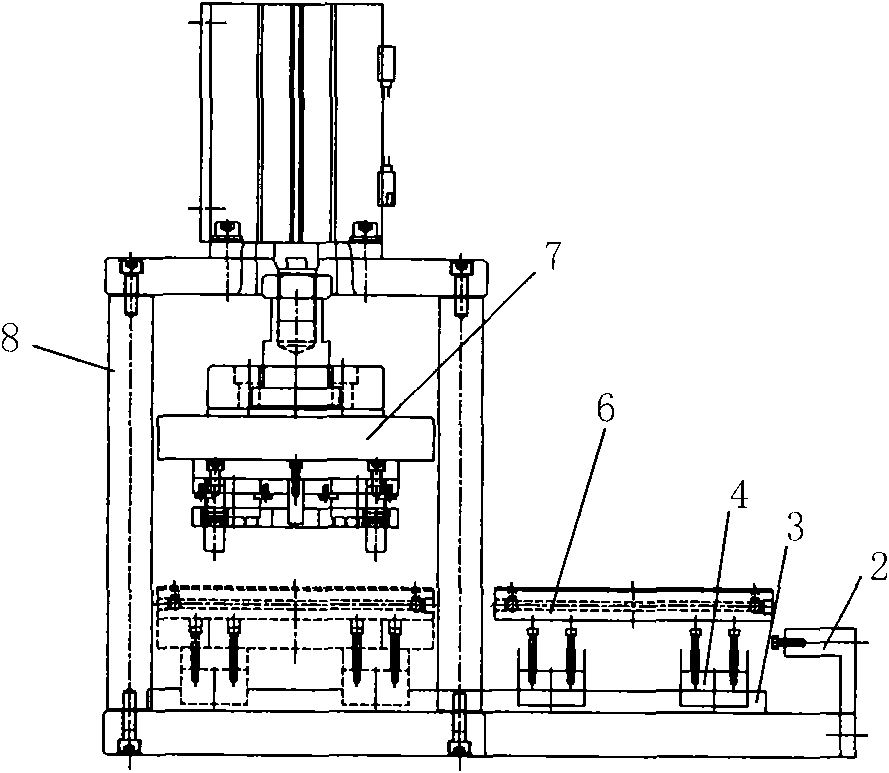

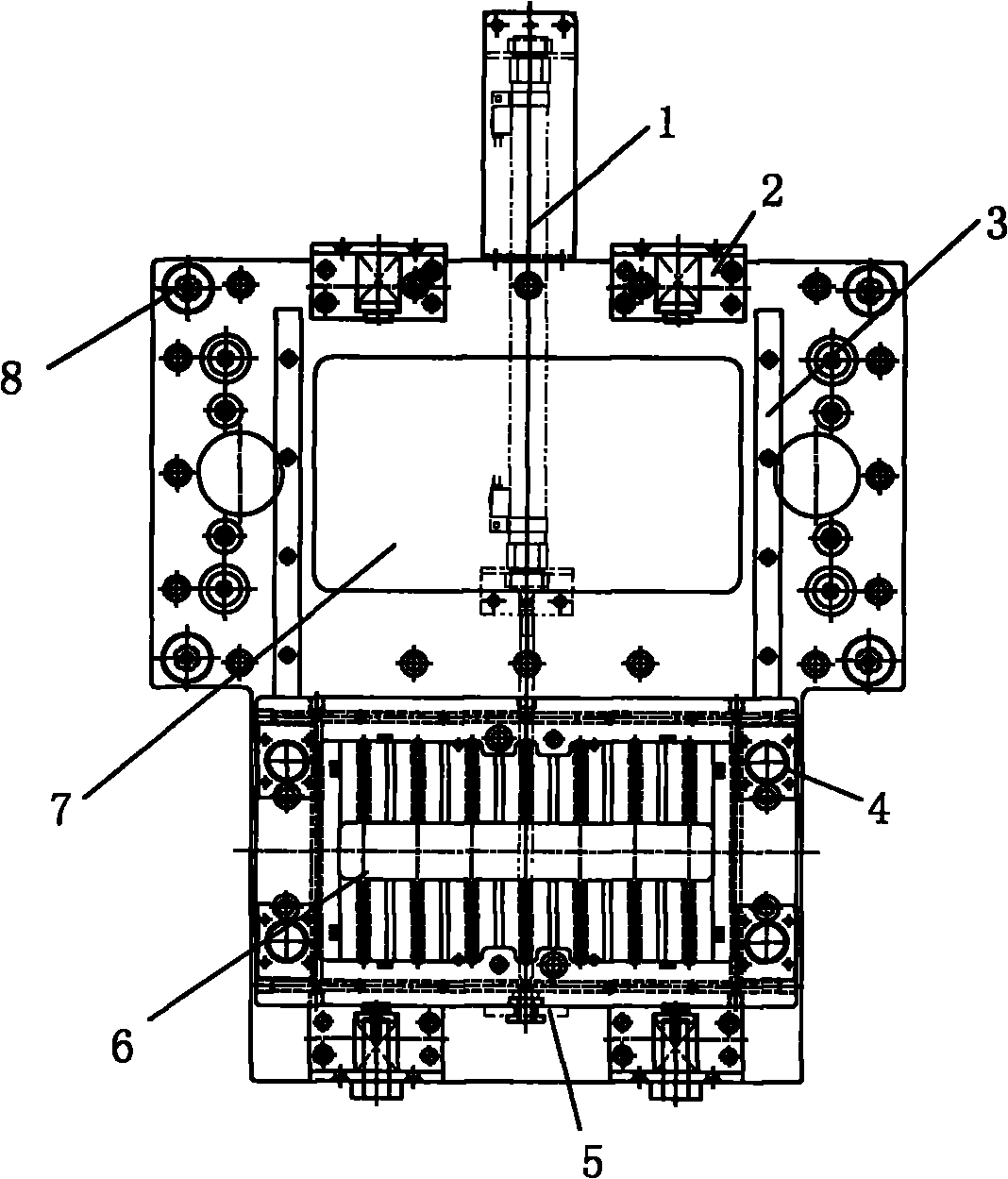

[0011] In this embodiment, the drawer-type structure large-scale integrated circuit flushing channel mold, such as figure 1 , figure 2 As shown, it includes a frame 8, a punch 7 located in the frame 8, a die 6 and a cylinder 1, and the two sides below the frame 8 are provided with linear guide rails 3 protruding from the frame 8, and the two linear guide rails 3 constitute The slideway, the two sides of the concave mold 6 are provided with sliders 4 that cooperate with the linear guide rail 3, so that the concave mold 6 can slide back and forth in the slideway through the cooperation of the linear guide rail 3 and the slider 4, and the cylinder 1 is fixed on the frame 8, and the cylinder 1. The piston rod is connected with the end of the die 6 to push the die 6 to slide in the slideway. Limiting blocks 5 are provided at both ends of the slideway to limit the position of the die 6 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com