Full-automatic separation sheet production equipment

A fully automatic, spacer technology, used in metal processing, strip winding, thin material processing, etc., can solve problems such as time-consuming, increased production costs, and reduced production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

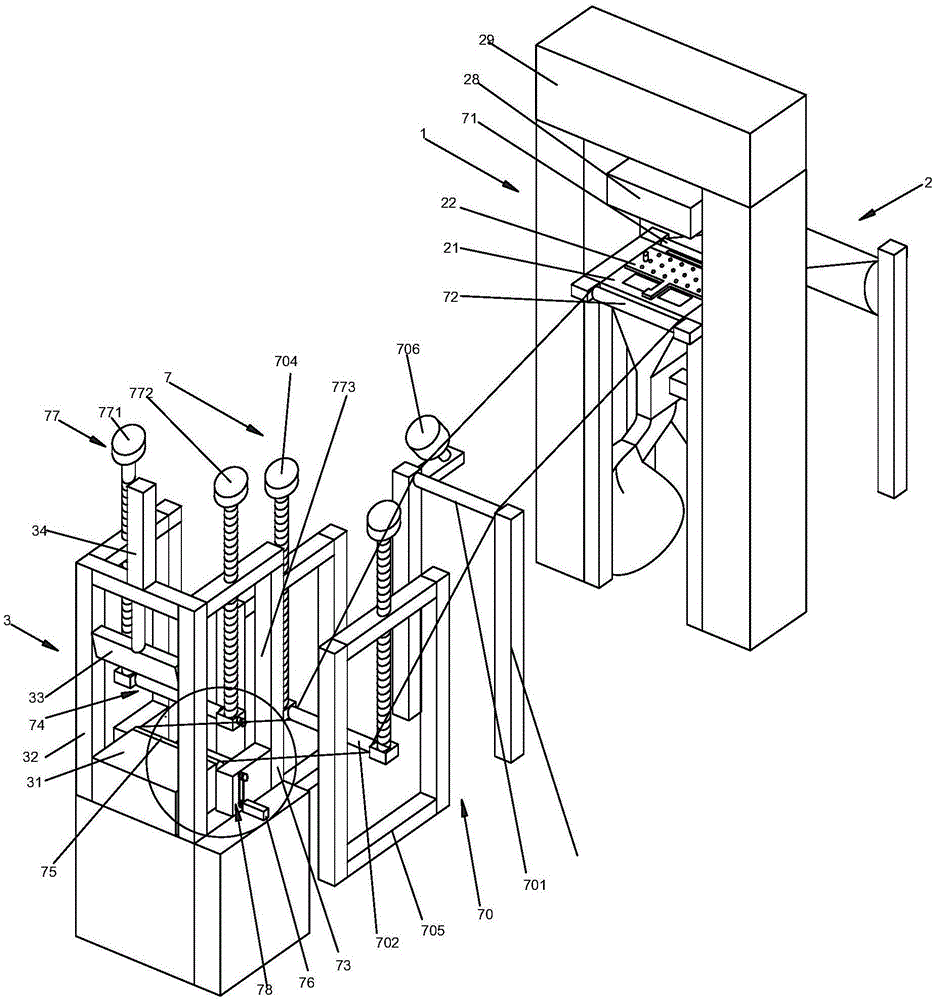

[0063] Such as figure 2 as well as image 3 As shown, the present embodiment proposes a fully automatic production spacer equipment, including:

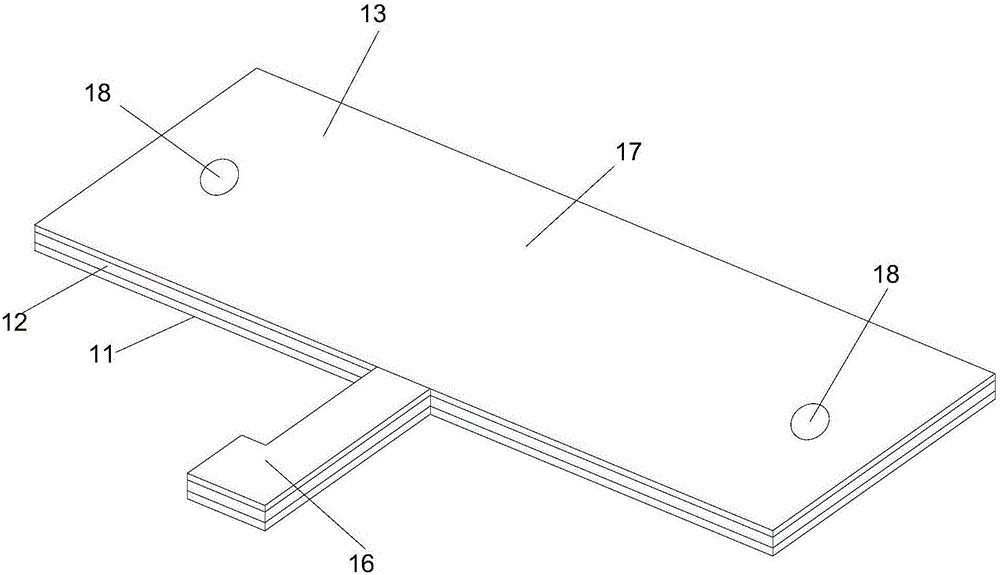

[0064] Convoluting device 1, it comprises the convoluting tube 11 that is used for convoluting adhesive film, has realized the continuous supply of adhesive film, and convoluting tube 11 is supported by cylinder support body 12;

[0065] Punching machine 2, it comprises gantry frame 29, and punching portion 28 is installed on the gantry frame 29, and the just below punching portion 28 is the punching station; The punching portion 28 just below is provided with bearing plate 21 and places mold 22, places The mold 22 is installed on the bearing plate 21, the placing mold 22 is used to place the semi-finished product, and the placing mold 22 is provided with a positioning column 24; and a support frame, which supports the bearing plate 21;

[0066] Adhesive film slicing mechanism 3, it comprises: slicing table 31, convoluting cylinde...

Embodiment 2

[0080] The difference between this embodiment and Embodiment 1 is only that: in order to avoid the punching mechanism 1 from crushing the semi-finished product due to rubber dust on the mold 22 when the semi-finished product is processed again, the present embodiment is provided with an air spray gun 5 .

[0081] Such as figure 2 , Figure 6 as well as Figure 9 As shown, the full-automatic production spacer equipment also includes the air spray gun 5, and the air spray gun 5 includes:

[0082] Mounting seat 51, it is arranged on the inner side of a gantry frame 29, is provided with drive cavity 511 in the mounting seat 51, and the first central axis 512 that is positioned at the vertical direction is erected on the bottom surface of drive cavity 511, offers on the mounting seat 51 side. A slide groove 513 communicating with the drive chamber 511;

[0083] The air nozzle 52 is provided with an air connection hole (not shown) and an air outlet for communicating with an exte...

Embodiment 3

[0103] The difference between this embodiment and Embodiment 2 is that, in order to prevent the rubber shavings from being blown to the ground and pollute the working environment, this embodiment adds a rubber shavings storage mechanism.

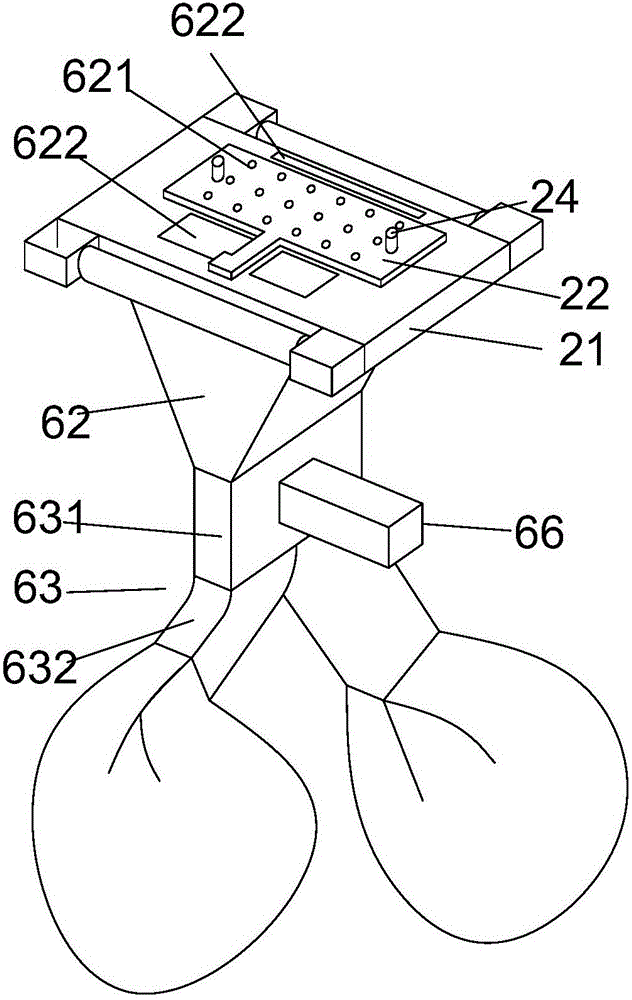

[0104] Such as figure 2 As shown, in this embodiment, the fully automatic production spacer equipment also includes a rubber scrap storage mechanism 6, such as Figure 4 as well as Figure 5 As shown, the rubber scrap storage mechanism 6 includes:

[0105] Fence 61, it is arranged on two placement molds 22 besides, with every surrounding around placement mold 22;

[0106] Two receiving funnels 62, which are all arranged on the bottom surface of the bearing plate 21, each receiving funnel 62 is set opposite to a placing mold 22, and the receiving funnel corresponding to each is provided on the supporting plate 21 next to each placing mold 22 62 connected chip drop holes 621, and each placing mold 22 is also provided with a knife setting h...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com