A kind of machining equipment with the function of recycling cutting waste

A waste recycling and functional technology, which is applied to the cleaning methods of tools, metal processing, cleaning methods and utensils, etc., can solve the problems of waste recycling troubles and unfavorable recycling, and achieve the effect of good recycling and good effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0037] The specific implementation manner of the present invention will be described below in conjunction with the accompanying drawings.

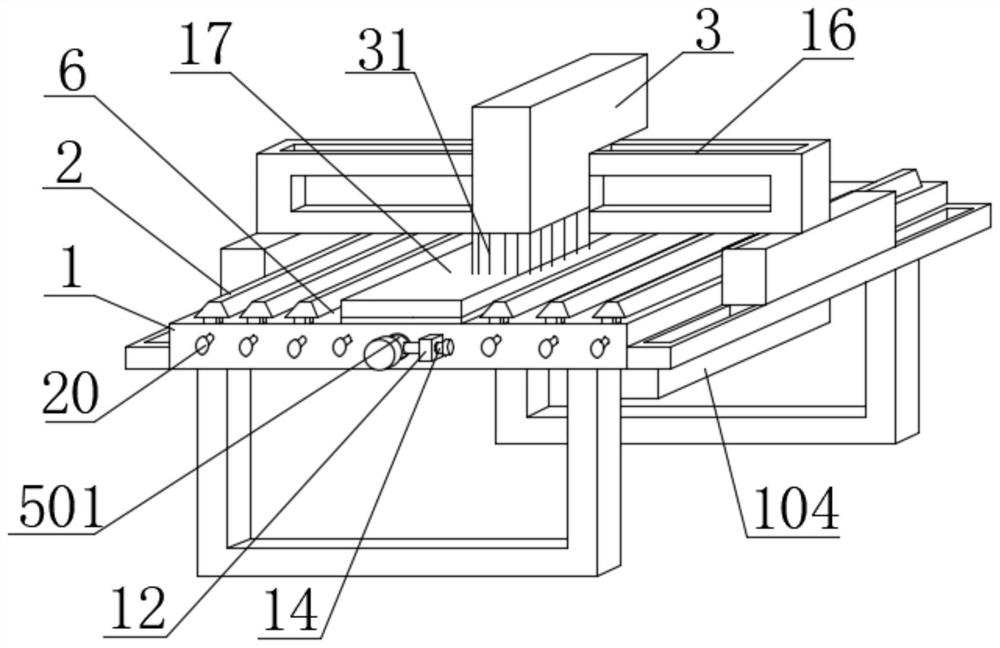

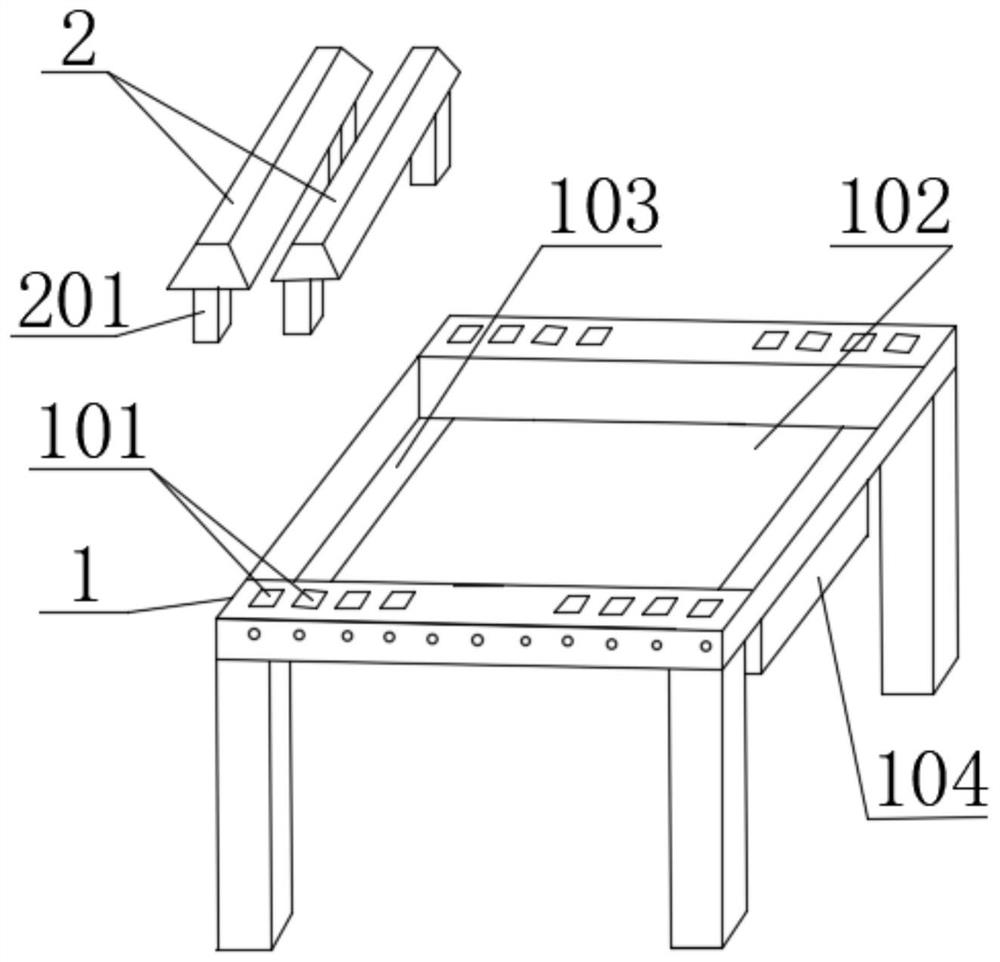

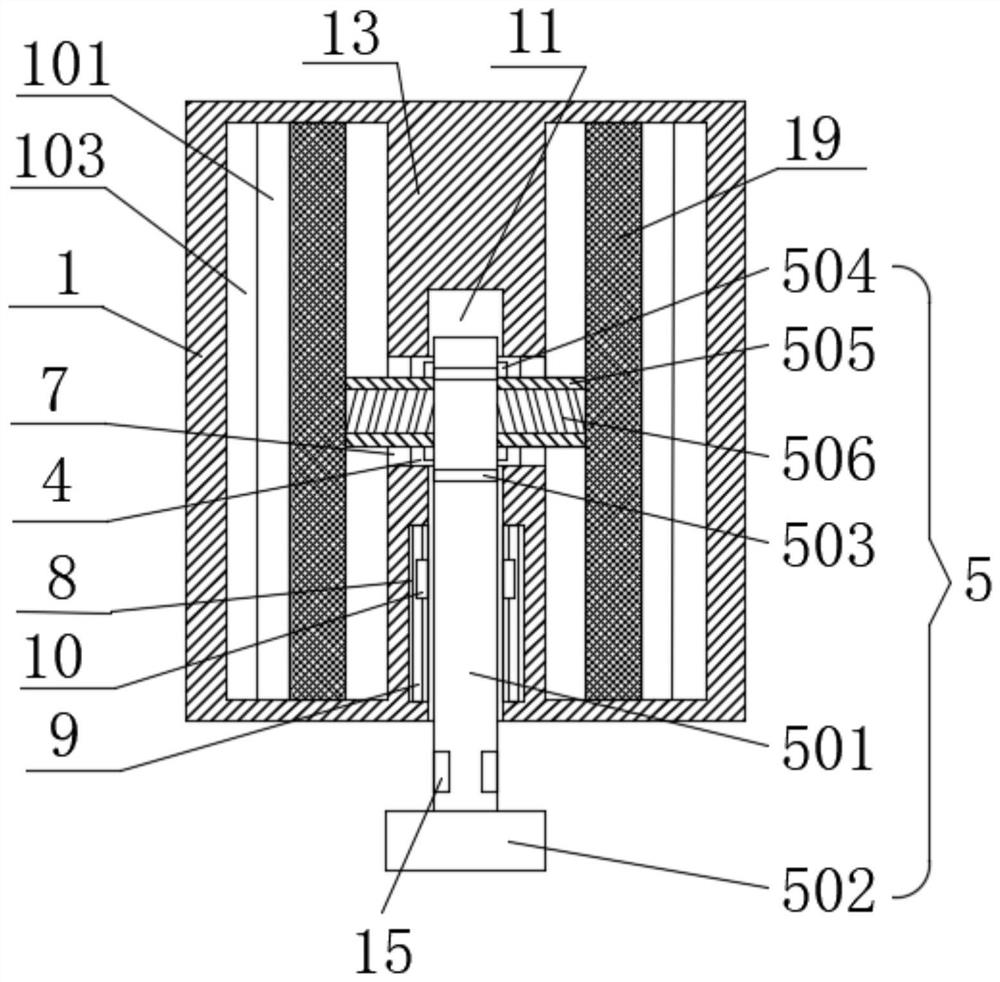

[0038] Such as figure 1 and figure 2 As shown, the machining equipment with the function of recycling cutting waste in this embodiment includes a frame 1, and guide rails are respectively provided on both sides of the frame 1, and horizontal linear modules 16 sliding along the guide rails are installed on the guide rails on both sides. , a knife rest 3 is installed on the horizontal linear module 16, a cutting knife is installed in the middle of the head of the knife rest 3, and a brush 31 is provided at the surrounding position;

[0039] The frame 1 is provided with a material receiving chute 102, and a material retaining plate 17 is installed in the middle of the notch of the material receiving trough 102, and the notches on both sides of the material retaining plate 17 are provided with a plurality of trapezoidal trapezoids vertically...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com