Rail wheel

A wheel and track technology, applied in the field of rail wheels, can solve the problems of cost and difficulty, achieve the effect of simple and effective disassembly, and reduce friction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

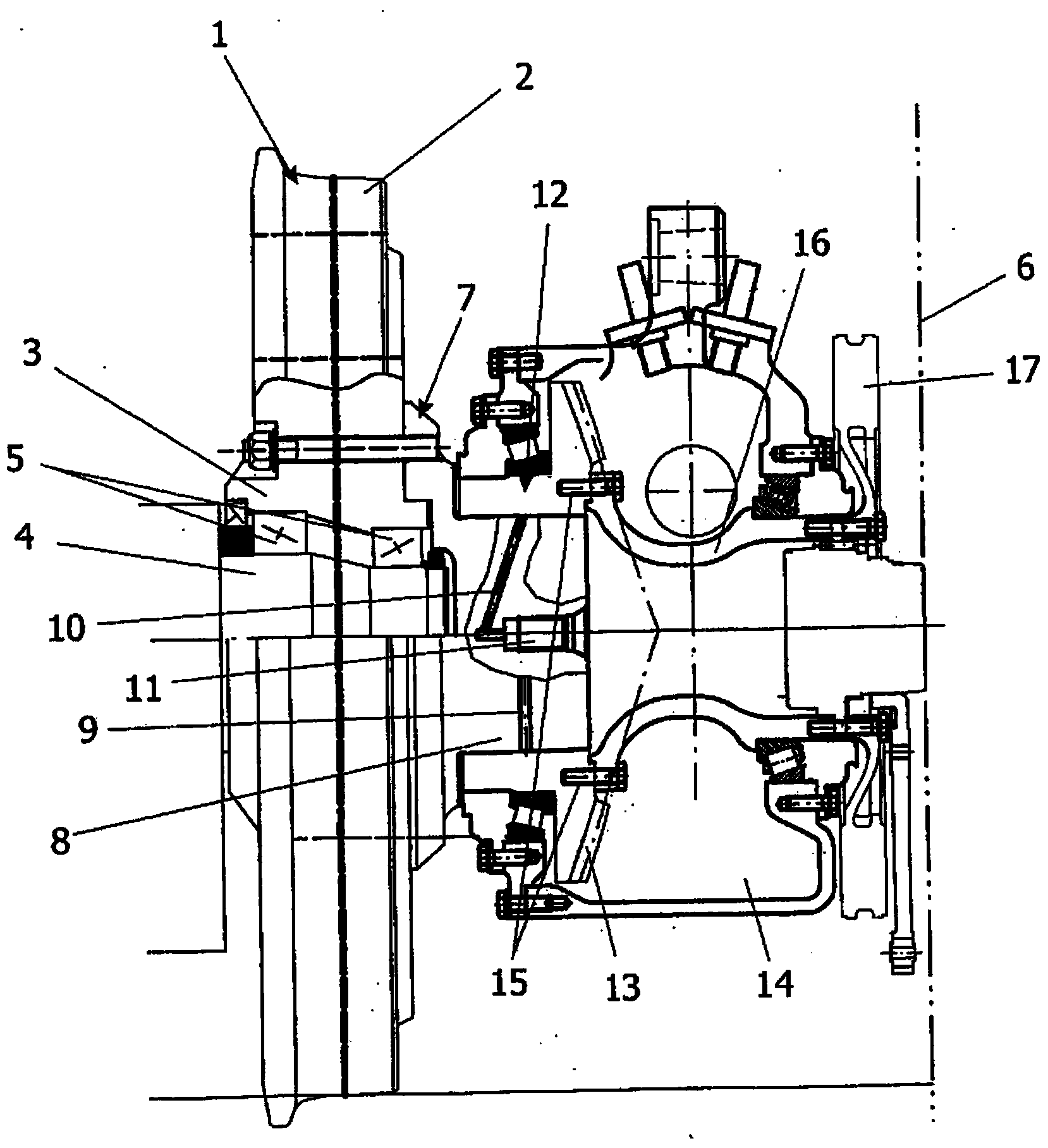

[0017] A rail wheel 1 can be identified in the drawings. The rail wheel 1 has a rim 2 and a hub 3 . The rim and hub are connected to one another via webs which cannot be clearly identified in the view shown here. The rail wheel 1 can be constructed in one piece or in multiple pieces. The hub 3 of the rail wheel 1 runs around a fixed axle 4 . The individual bearings 5 for the hub 3 are schematically shown. The rail wheel 1 is mounted on the axle 4 from the right in the view in the drawing and should also remain accessible from this right for future installation and maintenance work. The right side here is the side that is accessible from the side of the rail vehicle that is not shown. The two-dot dash line provided with the reference numeral 6 indicates the lateral delimitation of the rail vehicle.

[0018] Now, in the construction of the rail wheel 1 shown here, the intermediate element 7 is connected to the rail wheel 1 in a rotationally fixed manner. For this purpose...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com