Precise perforating equipment used for notebook computer bottom plate

A technology for punching equipment and notebooks, which is applied in the direction of drilling/drilling equipment, metal processing equipment, boring/drilling, etc., which can solve the problem of low safety and achieve the effect of easy collection and good fixation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

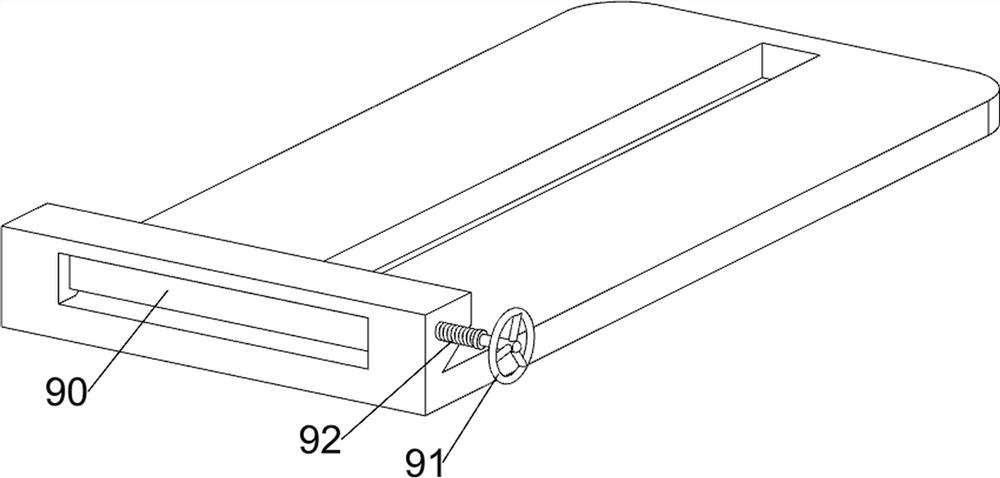

[0029] A device for precise punching of notebook bottom plates, such as figure 1 and figure 2 As shown, it includes a base 1, an operating table 2, a punching mechanism 3 and a clamping mechanism 4. The base 1 is provided with an operating table 2, the operating table 2 is provided with a punching mechanism 3, and the punching mechanism 3 is provided with a clamping mechanism. Tight mechanism4.

[0030] When people need to use this equipment, first people place the bottom plate on the right side of the console 2, then people can start the punching mechanism 3, and the punching mechanism 3 operates to punch holes on the left side of the bottom plate, while the punching mechanism 3 drives The clamping mechanism 4 operates, so that the clamping mechanism 4 clamps the bottom plate, and then after the left side of the bottom plate is punched, the punching mechanism 3 moves upward to separate from the bottom plate, and the punching mechanism 3 moves upward so that the clamping mec...

Embodiment 2

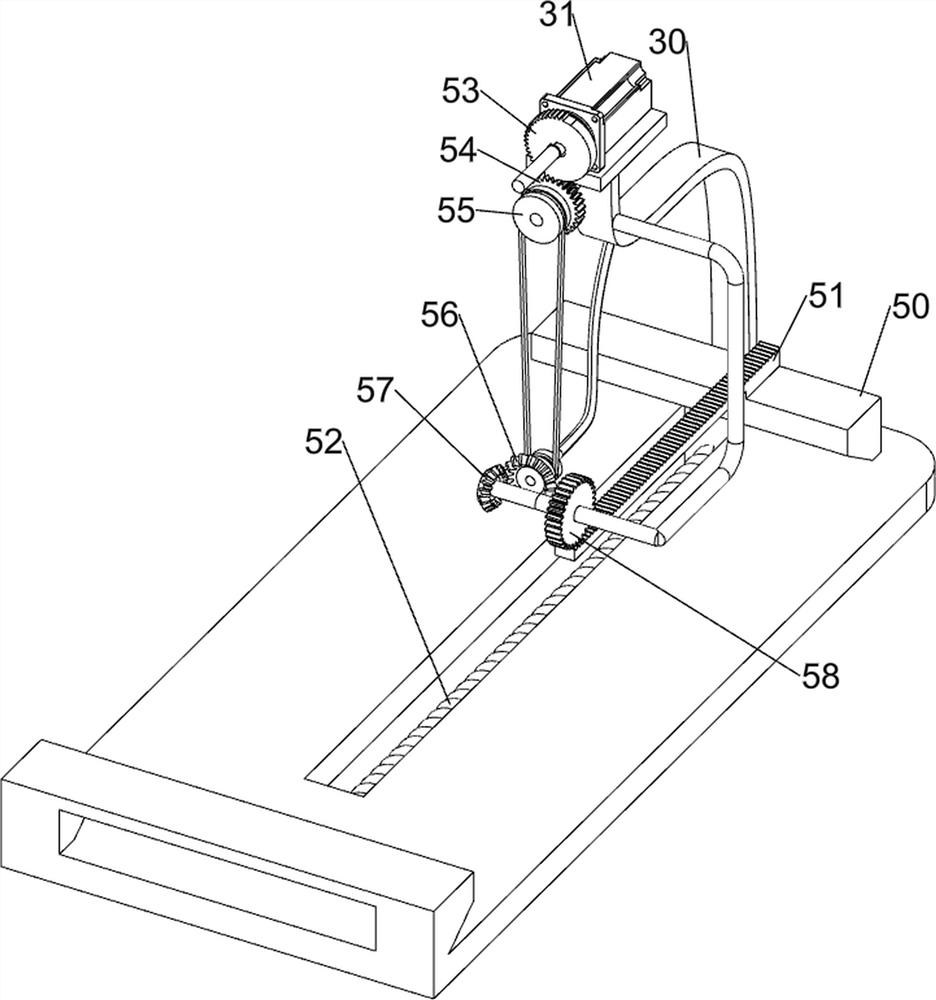

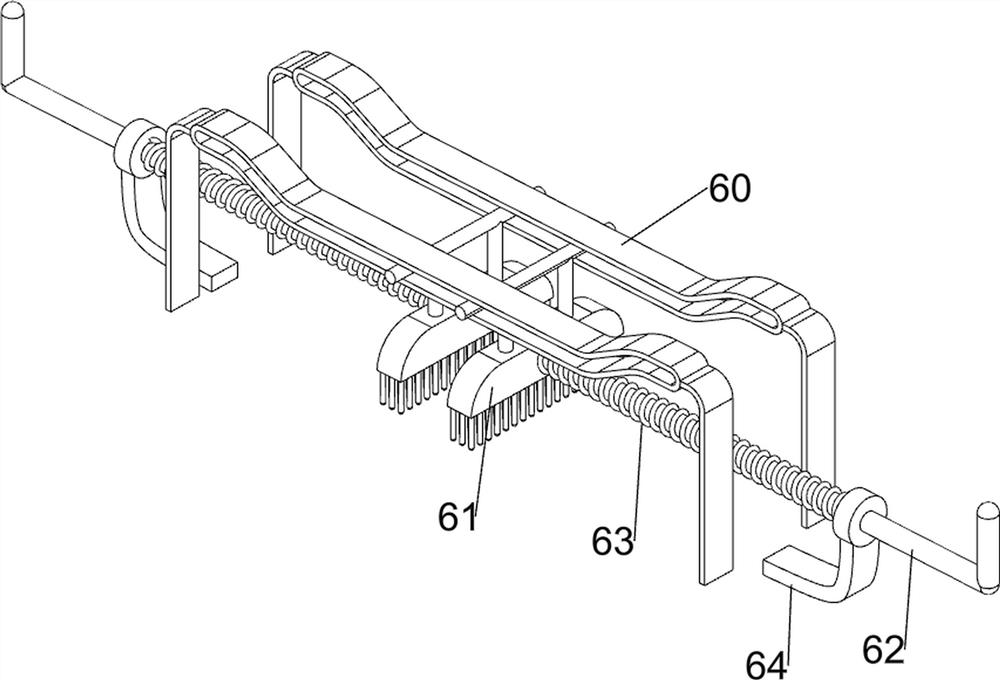

[0035] On the basis of Example 1, such as figure 1 , image 3 , Figure 4 , Figure 5 , Figure 6 and Figure 7 Shown, also comprise propulsion mechanism 5, and propulsion mechanism 5 comprises push block 50, rack 51, the 3rd spring 52, missing gear 53, first full gear 54, transmission assembly 55, first bevel gear 56, second bevel Gear 57 and the second full gear 58, sliding type is provided with push block 50 on the console 2, is provided with rack 51 on the push block 50, is provided with the 3rd spring 52 between push block 50 and console 2, servomotor 31 The output shaft is provided with a missing gear 53, and the first full gear 54 is rotatably arranged on the supporting seat 30. The first full gear 54 meshes with the missing gear 53, and the supporting seat 30 is rotatably provided with a first bevel gear 56. 30 upper rotary type is provided with the second bevel gear 57, is provided with transmission assembly 55 between the first bevel gear 56 and the first full g...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com