Furniture plate double-row control hole puncher

A punching machine and plate technology, applied in metal processing and other directions, can solve the problems of high labor intensity, bending of furniture plates, low safety factor, etc., and achieve the effects of good equipment stability, uniform internal and external structure, and high degree of automation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The preferred embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings, so that the advantages and features of the present invention can be more easily understood by those skilled in the art, so as to define the protection scope of the present invention more clearly.

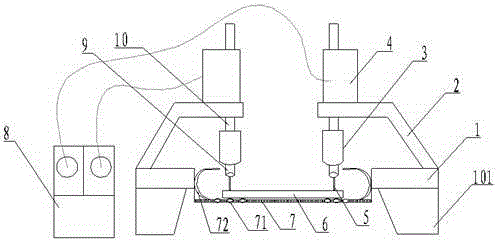

[0016] see figure 1 , the embodiment of the present invention includes:

[0017] The double-row control punching machine for furniture panels includes: a base, the base is made of cast iron material, feet are set at the lower end of the base, and two left and right oblique arm brackets are set at the upper end of the base . Above the inclined arm support is a horizontal surface, and a motor is fixed on the inclined arm support. The motor is connected with a speed regulating device, and is connected to a power pack through a power cord. The power pack adopts a voltage stabilizer, so that the power The group voltage remains stable.

[0018] At t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com