Assembly-line-type annular perforating device for cigarettes

A punching device and flow-through technology, applied in measuring devices, tobacco, cigarette manufacturing, etc., can solve the problems of inaccurate pressure/voltage converter pressure, tobacco blowing out, affecting the quality of cigarettes, etc., and achieve the convenience of mass production Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

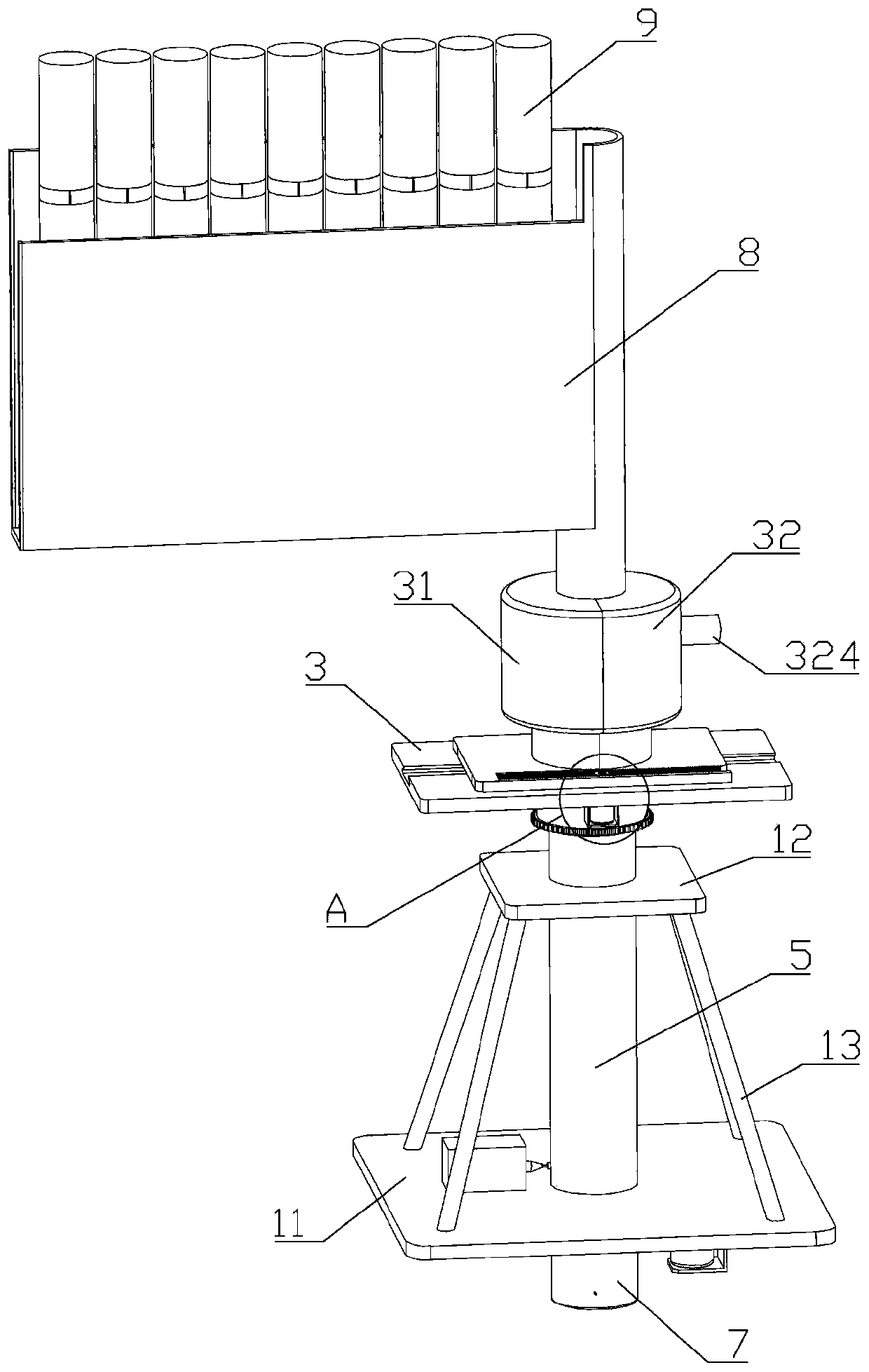

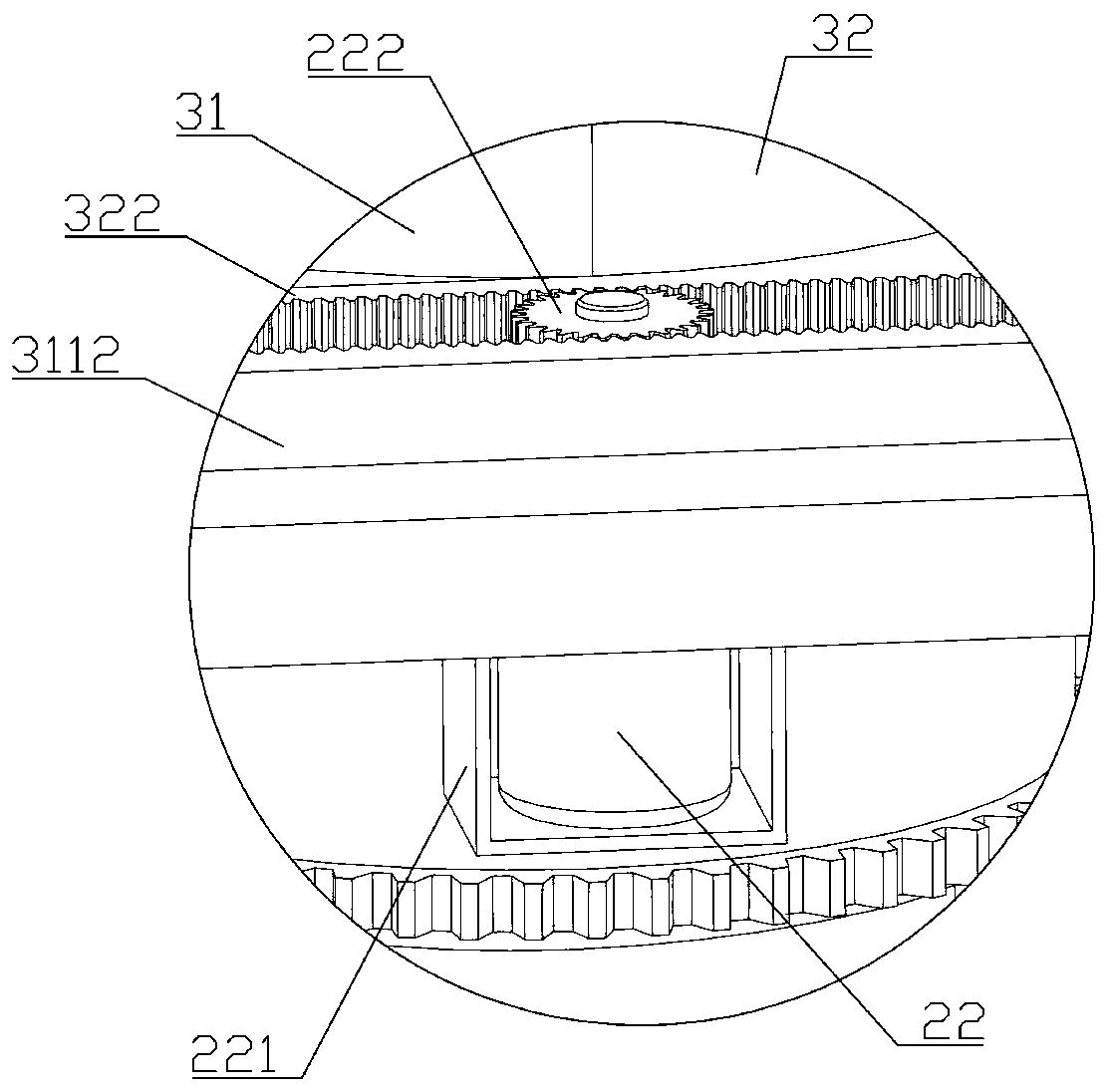

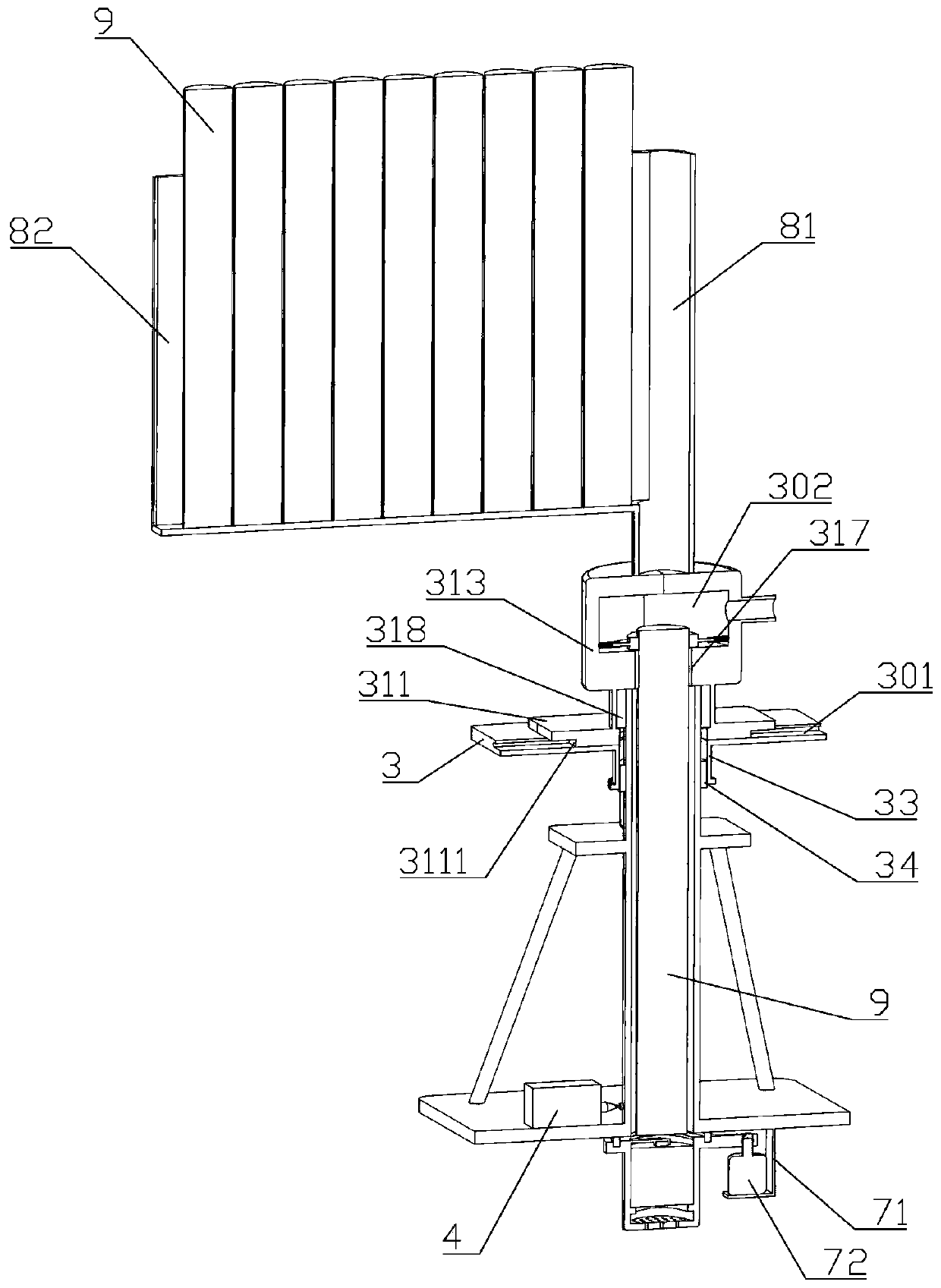

[0041] Such as Figure 1-13 As shown, it includes a mounting frame, an industrial computer, a first detection cylinder 5 and a laser punch 4. The laser head of the laser punch 4 passes through the wall of the first detection cylinder 5, and the laser output end of the laser head Located inside the first detection cylinder 5, the laser punch 4 and the first detection cylinder 5 are all installed on the mounting frame, the input end of the laser punch 4 is connected with the output end of the industrial computer, and the first detection cylinder 5 uses For placing cigarettes 9, a cigarette holding mechanism is rotated on the first detection cylinder 5, and a feeding mechanism 8 is also arranged above the cigarette holding mechanism, wherein, the feeding mechanism 8 is fixedly installed on the cigarette holding by a separate bracket. The upper part of the mechanism is not in contact with the cigarette holder mechanism, so as to avoid interfering with the normal operation of the c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com