Saw cutting end milling machine

An end milling and sawing technology, applied in metal processing machinery parts, clamping, supporting and other directions, can solve the problem of low efficiency of positioning operation and achieve the effect of improving construction efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

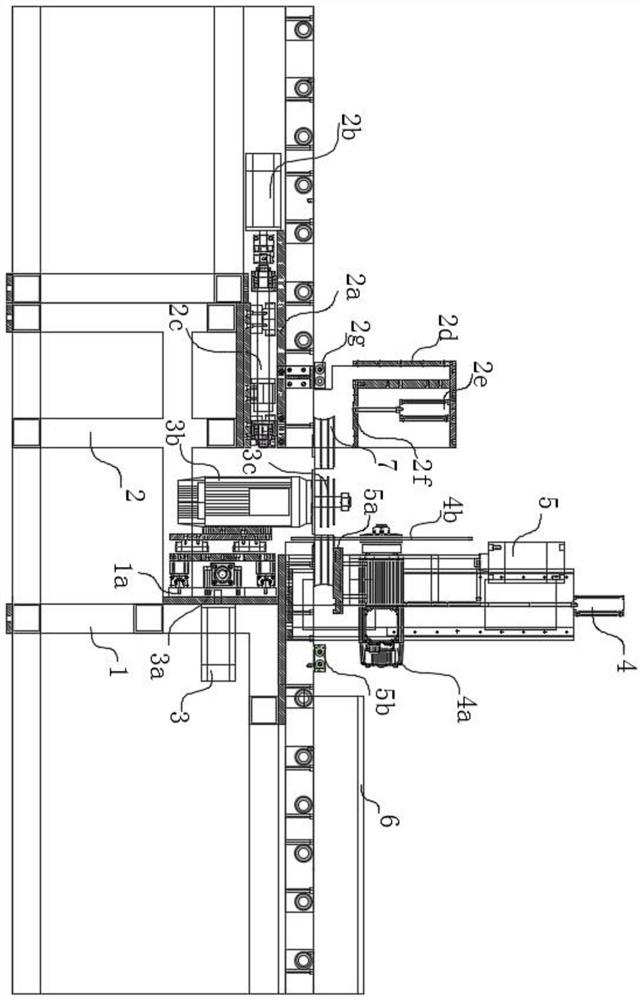

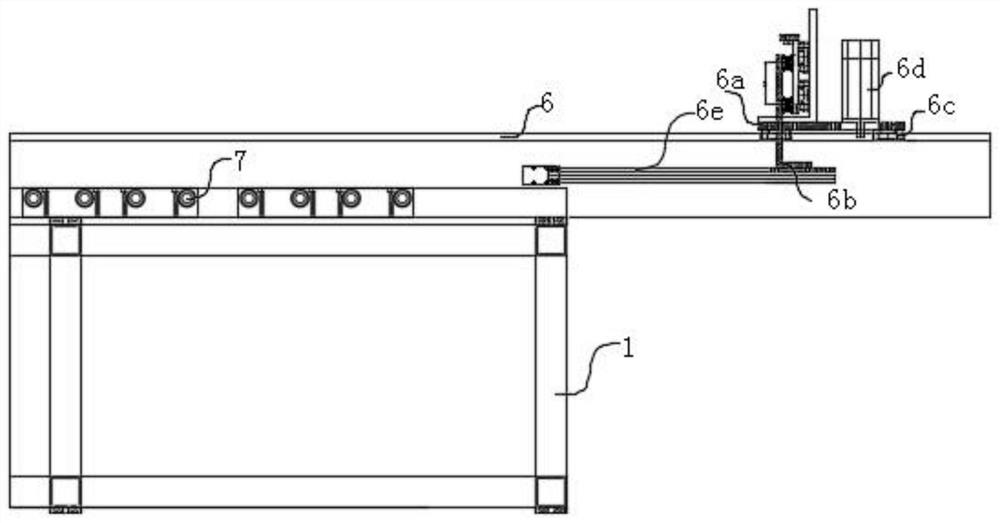

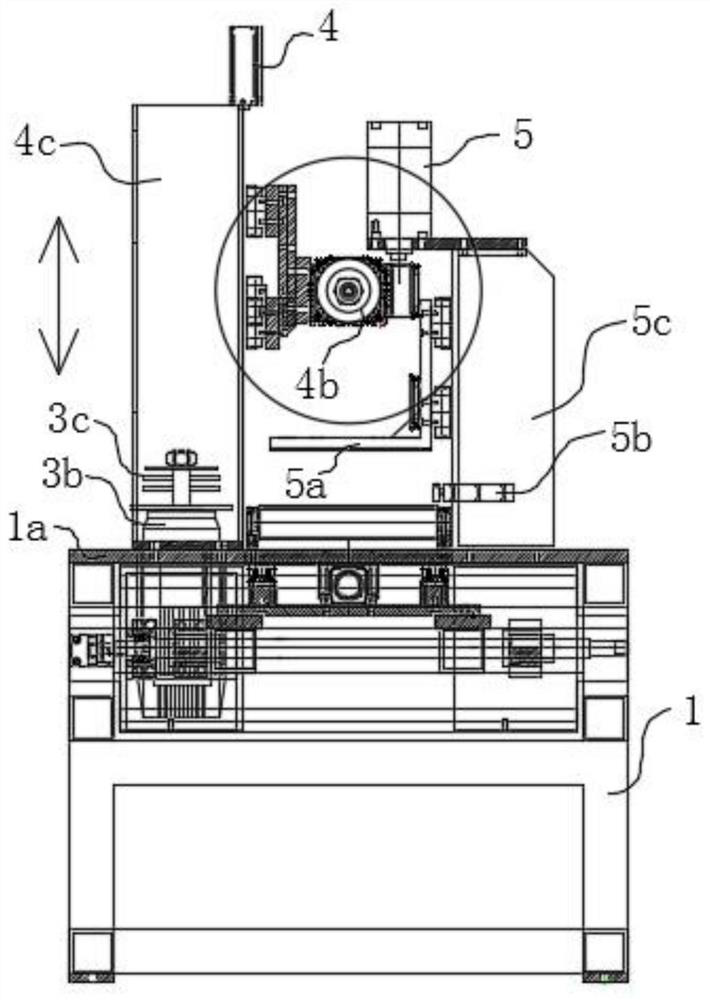

[0021] Such as Figure 1-5 As shown, a sawing end milling machine is disclosed in this embodiment, comprising a first conveying platform 1, a second conveying platform 2 installed at intervals in the same conveying direction as the first conveying platform 1, and a second conveying platform 2 installed on the first conveying platform 1 On the conveying platform 1, the 90-degree saw blade motor 4a, which cuts off the multiple profiles conveyed on the first conveying platform 1 and the second conveying platform 2, is installed on the first conveying platform 1 and in the horizontal direction The reciprocating motion carries out the milling cutter motor 3b that carries out horizontal end milling to the ends of a plurality of profiles cut off by the 90-degree saw blade motor 4a, and the feeding moving guide rail 6 installed on the first conveying platform 1 and the feeding moving guide rail 6 installed on the first conveying platform 1. The feeding manipulator 6e for conveying pro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com