Deep and shallow dock combination for manufacturing and shipping large prefabricated components and assembly line working method

A technology of prefabricated components and assemblies, applied in industrial buildings, water conservancy projects, underwater structures, etc., can solve problems such as difficulty in meeting requirements, aggravating construction period pressure, prefabrication and shipping cannot be carried out at the same time, to save construction time, The effect of ensuring safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

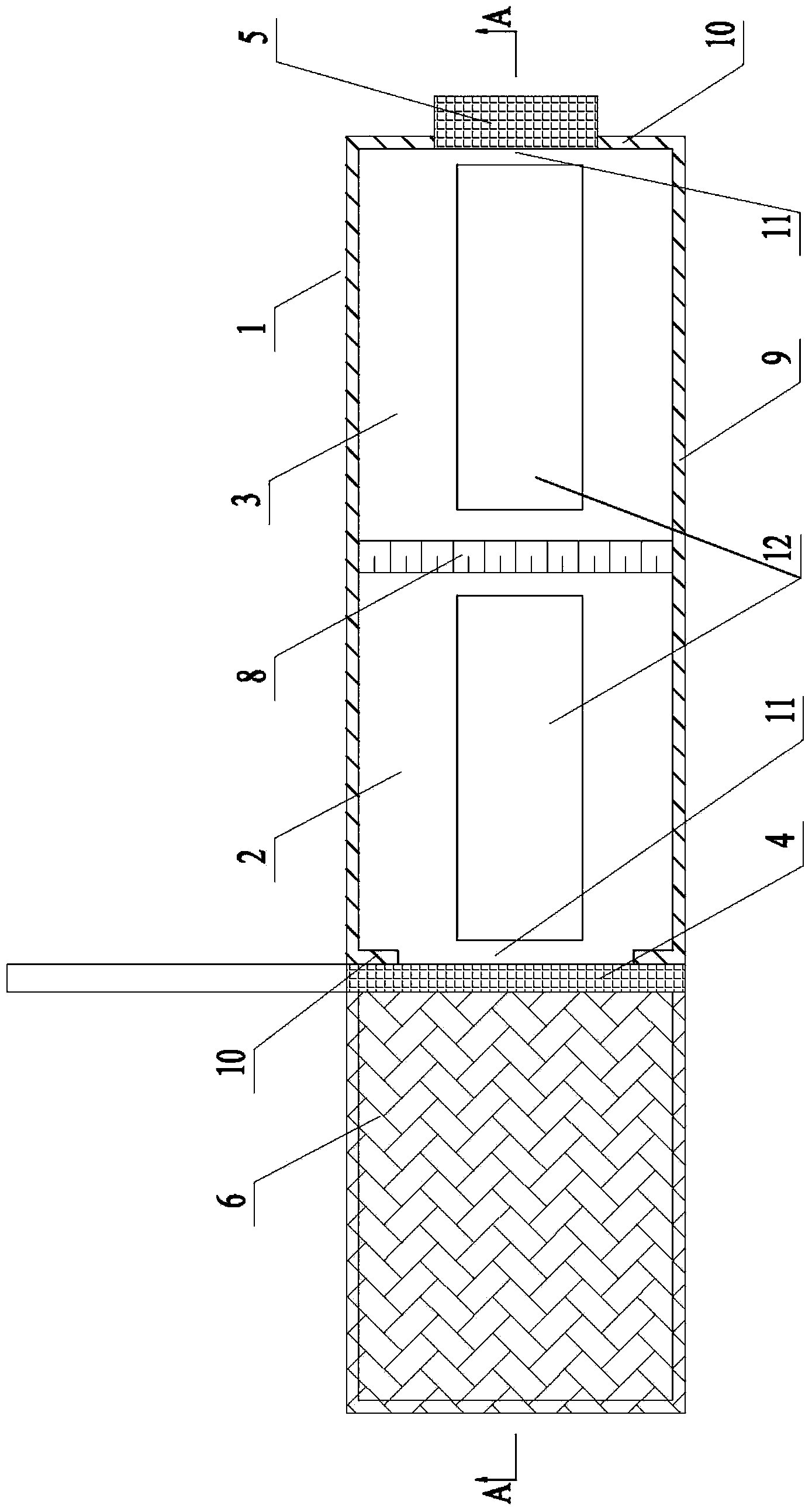

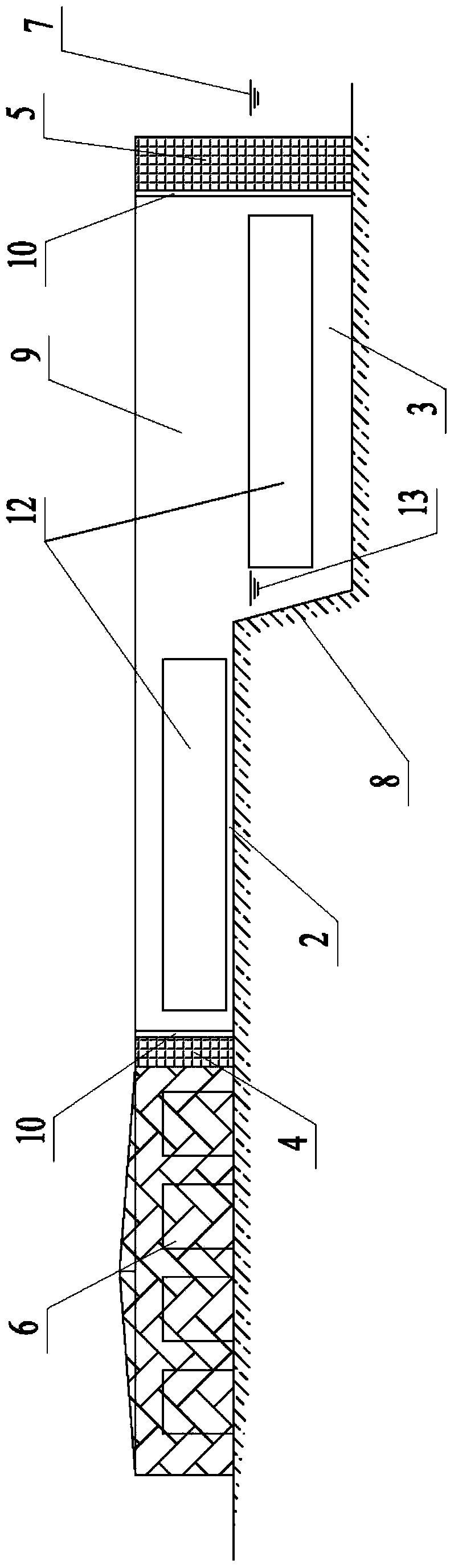

[0040] See figure 1 , figure 2 As shown, a deep-shallow dock assembly for producing and shipping large-scale prefabricated components of the present invention includes an enclosure 1 for preventing the ingress of seawater, and a first for large-scale prefabricated components 12 is provided in the enclosure. The shallow docking area 2 for secondary outfitting and floating and the deep docking area 3 for the second outfitting and shipping; one end of the enclosure is provided with a shallow docking door 4 for opening and closing the shallow docking area, the The other end of the enclosure is provided with a deep dock door 5 used to open and close the deep dock area and realize the drainage of the deep and shallow dock combination. The enclosure described in this embodiment completely encloses the shallow dock area and the deep dock area. An end of the enclosure opposite to the prefabrication workshop 6 is provided with a gate for the entry of large prefabricated components, and t...

Embodiment 2

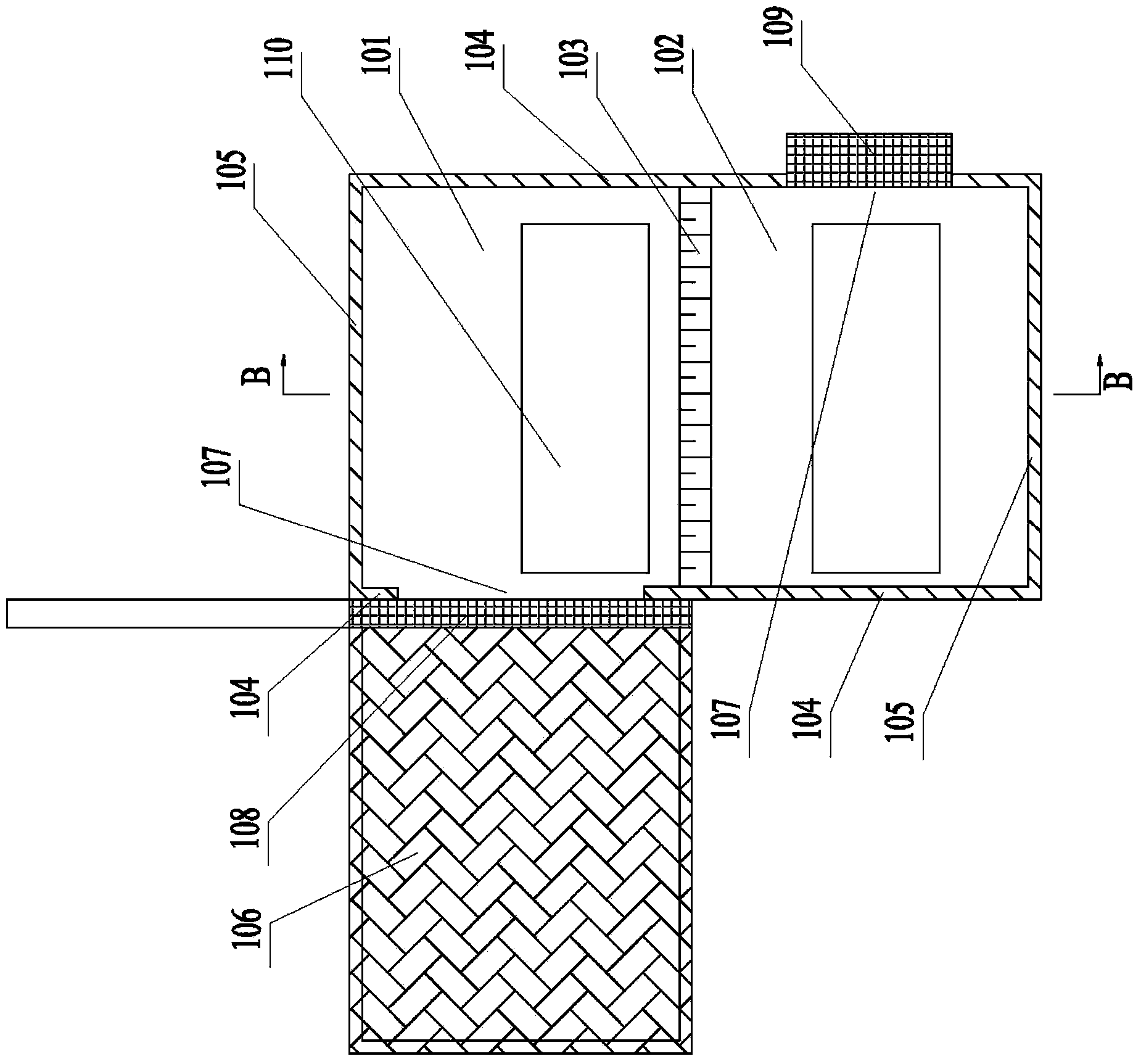

[0045] See image 3 , Figure 4 As shown, the outfitting field in this embodiment is an improvement on the basis of Embodiment 1. The technical content disclosed in Embodiment 1 will not be described repeatedly, and the content disclosed in Embodiment 1 also belongs to the content disclosed in this embodiment.

[0046] In this embodiment, the shallow docking area 101 and the deep docking area 102 are arranged side by side in sequence; the level of the bottom surface of the shallow docking area is higher than the level of the bottom surface of the deep docking area.

[0047] In this embodiment, a transition slope 103 is also provided at the connection between the shallow dock area and the deep dock area.

[0048] The enclosure in this embodiment includes two end barrier walls 104 and side barrier walls 105 arranged on the lower and lower sides of the two end barrier walls. In this embodiment, the upper end surfaces of the side retaining wall and the end retaining wall are in the same ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com