Assembly line type ultrahigh-pressure sterilizing equipment

An ultra-high pressure sterilization and ultra-high pressure technology, which is applied in the fields of ultra-high pressure food processing, food science, food preservation, etc., can solve the problems of inability to complete aseptic operation and increase the difficulty of operation, and achieve the effect of providing ultra-high pressure processing efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

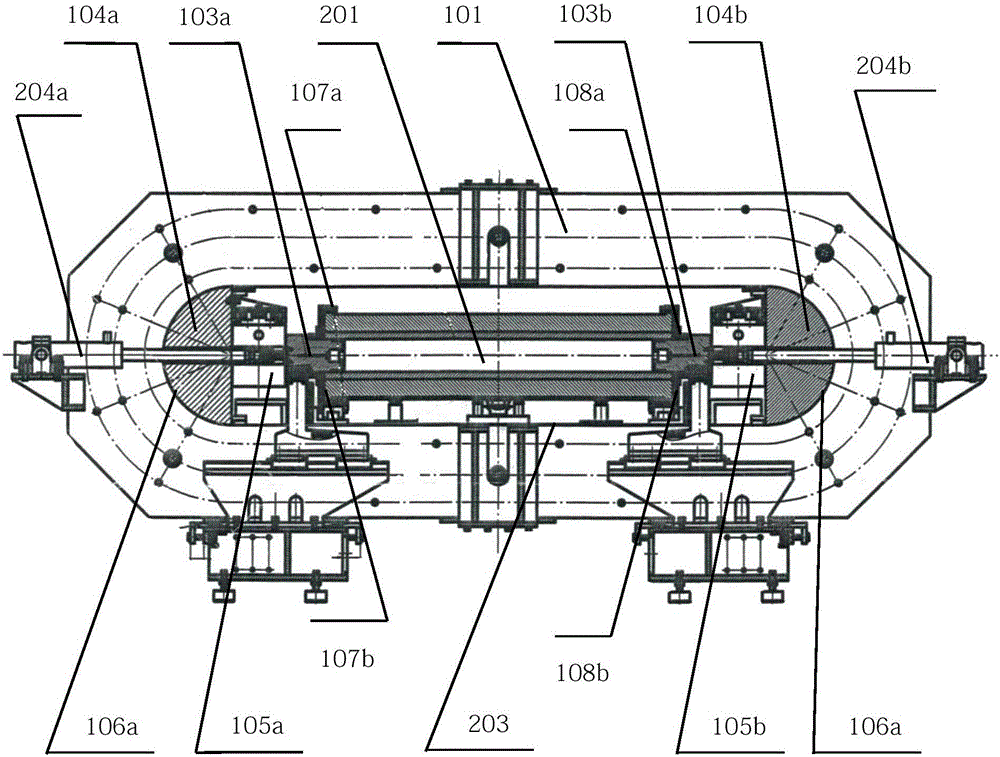

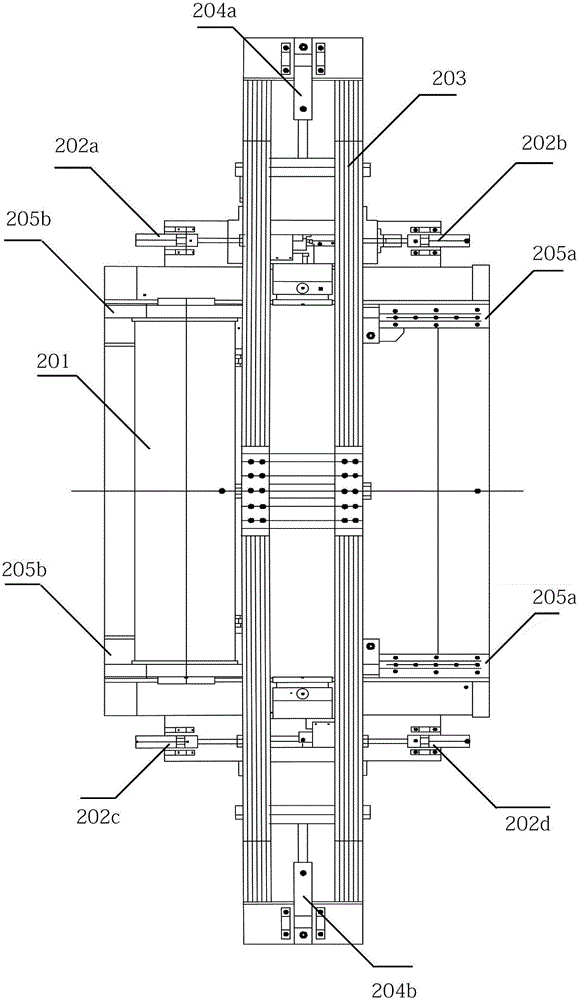

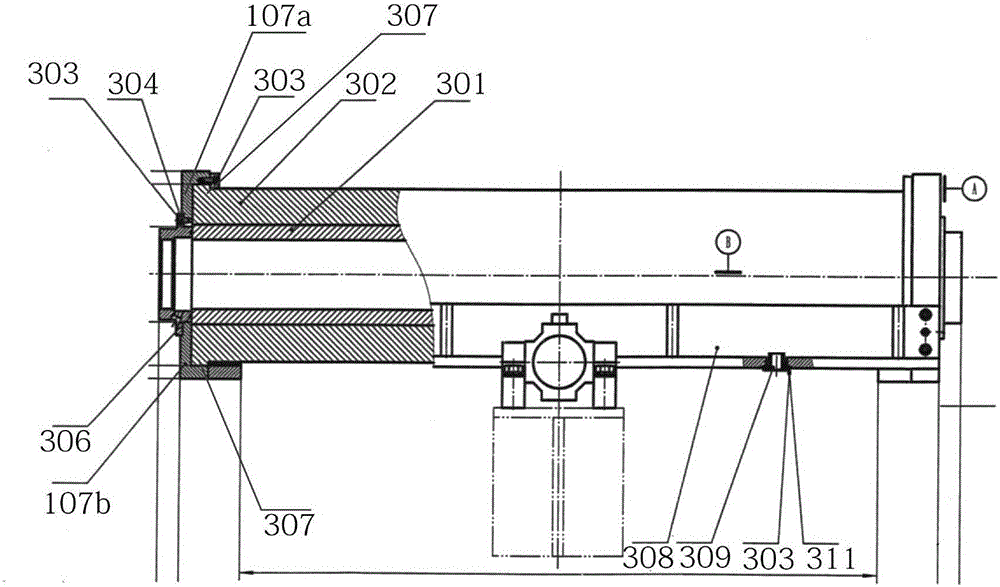

[0053] The ultra-high pressure equipment also includes a first stopper 104a and a second stopper 104b. The ultra-high pressure cylinder 201 is horizontally placed in the load-bearing frame 101 . The first block 104a and the second block 104b are used to directly or indirectly connect the bearing frame 101 and the ultra-high pressure cylinder 201 . According to a preferred embodiment, the load-bearing frame 101 is composed of two sets of steel plates, and each set of steel plates is composed of six steel plates through a water cutting process to form a hollow space enough to accommodate the ultra-high pressure cylinder 201 . The structure formed by the assembly of single steel plates can withstand greater pressure, and compared with the load-bearing frame of the overall solid structure, it saves residual materials and reduces costs. Water cutting can cut steel plate with any curve at one time, no heat and harmful substances will be generated during cutting, the material has no...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com