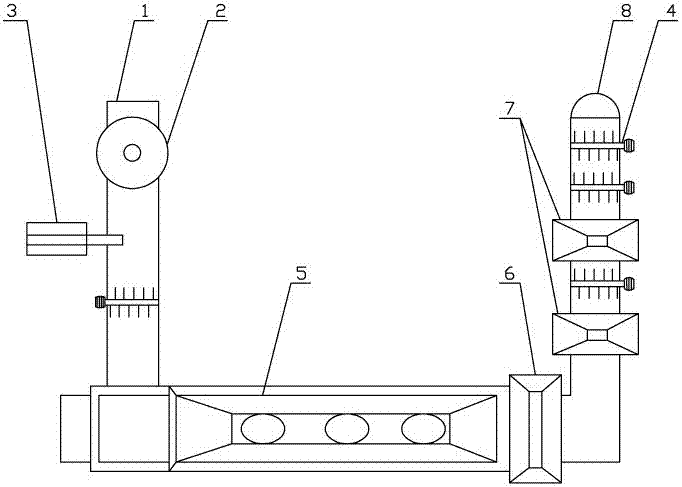

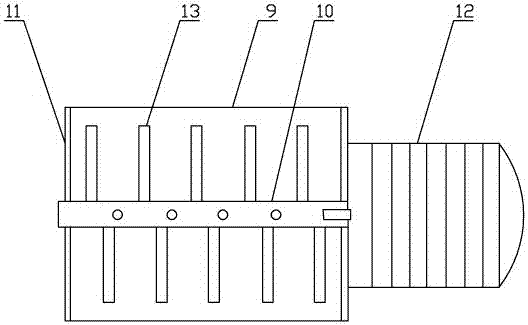

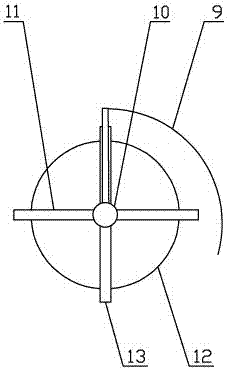

Mechanized production technique for producing Xiaoqu liquor with glutinous sorghum as raw material and device of spreading for cooling and mixing yeast thereof

A technology of small koji liquor and glutinous sorghum, applied in the field of mechanized brewing process and cooling koji device, can solve the problems of easy breeding of miscellaneous bacteria, affecting the quality of liquor, and low fusel oil content, so as to improve the temperature of raw materials entering the box, Effect of reducing grain agglomeration and viscosity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0034] A kind of mechanized brewing process of using glutinous sorghum as raw material to produce Xiaoqu Baijiu in this embodiment comprises the following steps:

[0035](1) Soaking grain: Soak glutinous sorghum in a grain soaking pot with 83°C hot water for 21 hours, the water volume is 14cm higher than the grain surface, cover the pot and rotate 4 times during the soaking process, and discharge the soaked grain after soaking grain Water, let it stand for 30 minutes, so that the water absorption rate of the grain can reach 44-47%;

[0036] (2) Cooking and gelatinization: put the soaked grain in a spherical low-pressure grain steamer, drain the water and discharge the pressure so that the pressure in the grain steamer rises to 0.06MPa, and then perform initial steaming. Water, the amount of water added is 3cm higher than the grain surface, cover and rotate the grain steaming pot for 1 turn, let it stand for 6 minutes, drain and discharge pressure to make the pressure in the gr...

Embodiment 2

[0048] A kind of mechanized brewing process of using glutinous sorghum as raw material to produce Xiaoqu Baijiu in this embodiment comprises the following steps:

[0049] (1) Soaking grain: Soak glutinous sorghum in a grain soaking pot with 80°C hot water for 23 hours, the water volume is 15cm higher than the grain surface, cover the pot and rotate 5 times during the soaking process, and discharge the soaked grain after soaking grain Water, let it stand for 20 minutes, so that the water absorption rate of the grain can reach 44-47%;

[0050] (2) Cooking and gelatinization: put the soaked grain in a spherical low-pressure grain steamer, drain the water and discharge the pressure so that the pressure in the grain steamer rises to 0.06MPa, and then perform initial steaming. The initial steaming time is 5 minutes. Open the lid and add 52°C Water, the amount of water added is 4cm higher than the grain surface, cover and rotate the grain steaming pot for 2 turns, let it stand for 4 ...

Embodiment 3

[0056] A kind of mechanized brewing process of using glutinous sorghum as raw material to produce Xiaoqu Baijiu in this embodiment comprises the following steps:

[0057] (1) Soaking grain: Soak glutinous sorghum in a grain soaking pot with 85°C hot water for 19 hours, the water volume is 12cm higher than the grain surface, cover the pot and rotate 3 times during the soaking process, and discharge the soaked grain after soaking grain Water, let it stand for 40 minutes, so that the water absorption rate of the grain can reach 44-47%;

[0058] (2) Cooking and gelatinization: put the soaked grain in a spherical low-pressure grain steamer, drain the water and discharge the pressure so that the pressure in the grain steamer rises to 0.06MPa, and then perform initial steaming. Water, the amount of water added is 2cm higher than the grain surface, cover and rotate the grain steaming pot for 2 turns, let it stand for 7 minutes, drain and discharge pressure to make the pressure in the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com