Automatic ink loader for computer print cartridge and ink loading method

A technology of automatic ink filling and ink cartridges, applied in printing and other directions, can solve the problems of cumbersome operation, inconvenient use of ink cartridges, inconvenient computer chain management, etc., to achieve the effect of improving work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

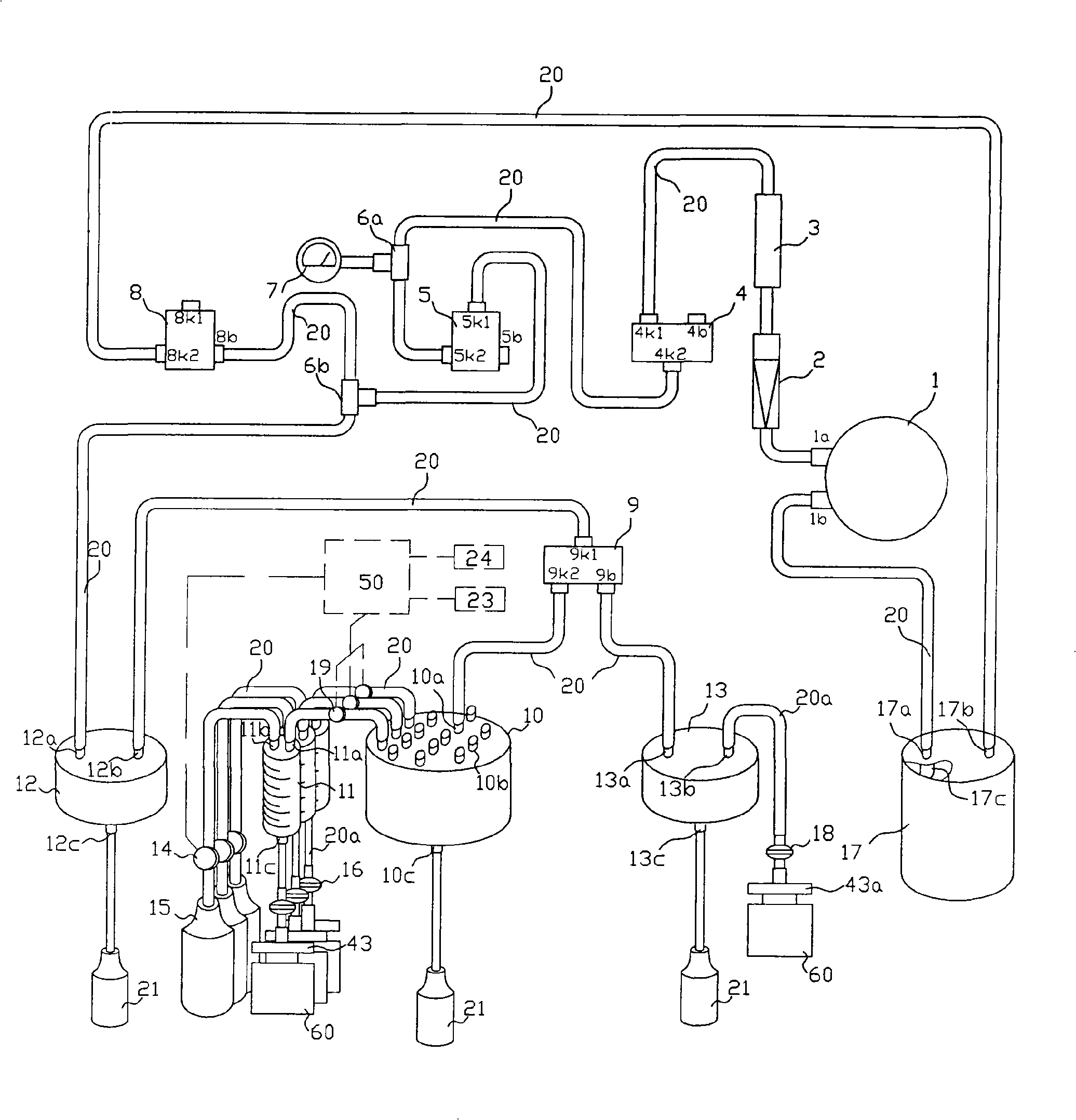

[0033] Ink of 14 kinds of types and colors is prepared in the ink adding machine of this embodiment, correspondingly has 14 ink measuring tubes and 14 ink measuring pumps. then in figure 1 The upper end of the shown vacuum distributor 10 is provided with 15 distribution gas ports, wherein a distribution gas port 10a is connected to a normally open port 9k2 of the residual ink valve 9 through a pipeline 20, and the remaining 14 distribution gas ports 10b are respectively passed through a pipeline 20 And 14 vacuum valves 19 are connected with an interface 11a of 14 ink measuring tubes 11 upper ends. Another interface 11 b at the upper end of each ink measuring tube is connected to the ink measuring pump 14 through a pipeline 20 , and the lower end of the ink measuring pump 14 is connected to the ink bottle 15 . The lower end interface 11c of each ink measuring tube 11 is connected to the ink injection head 16 through a hose 20a. Another normally open interface 9k1 of the res...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com