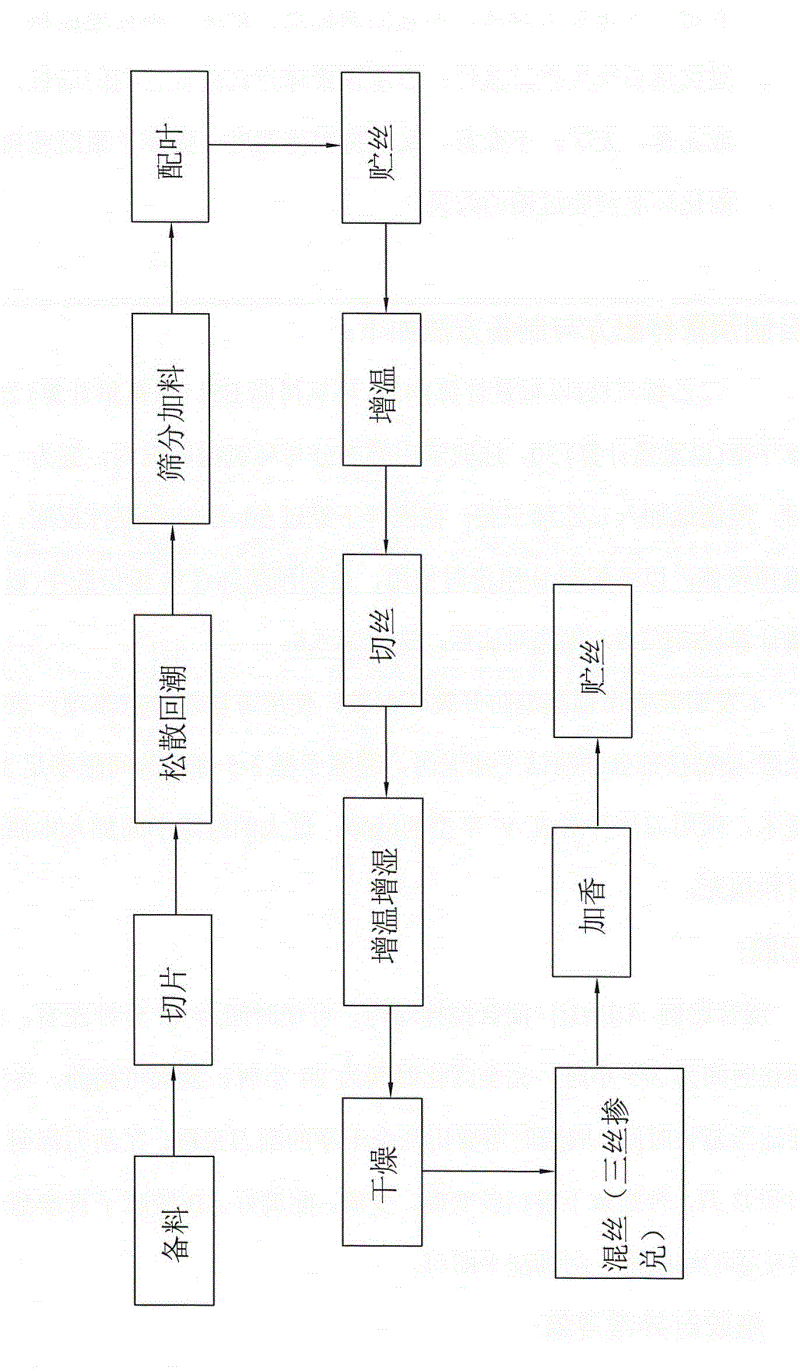

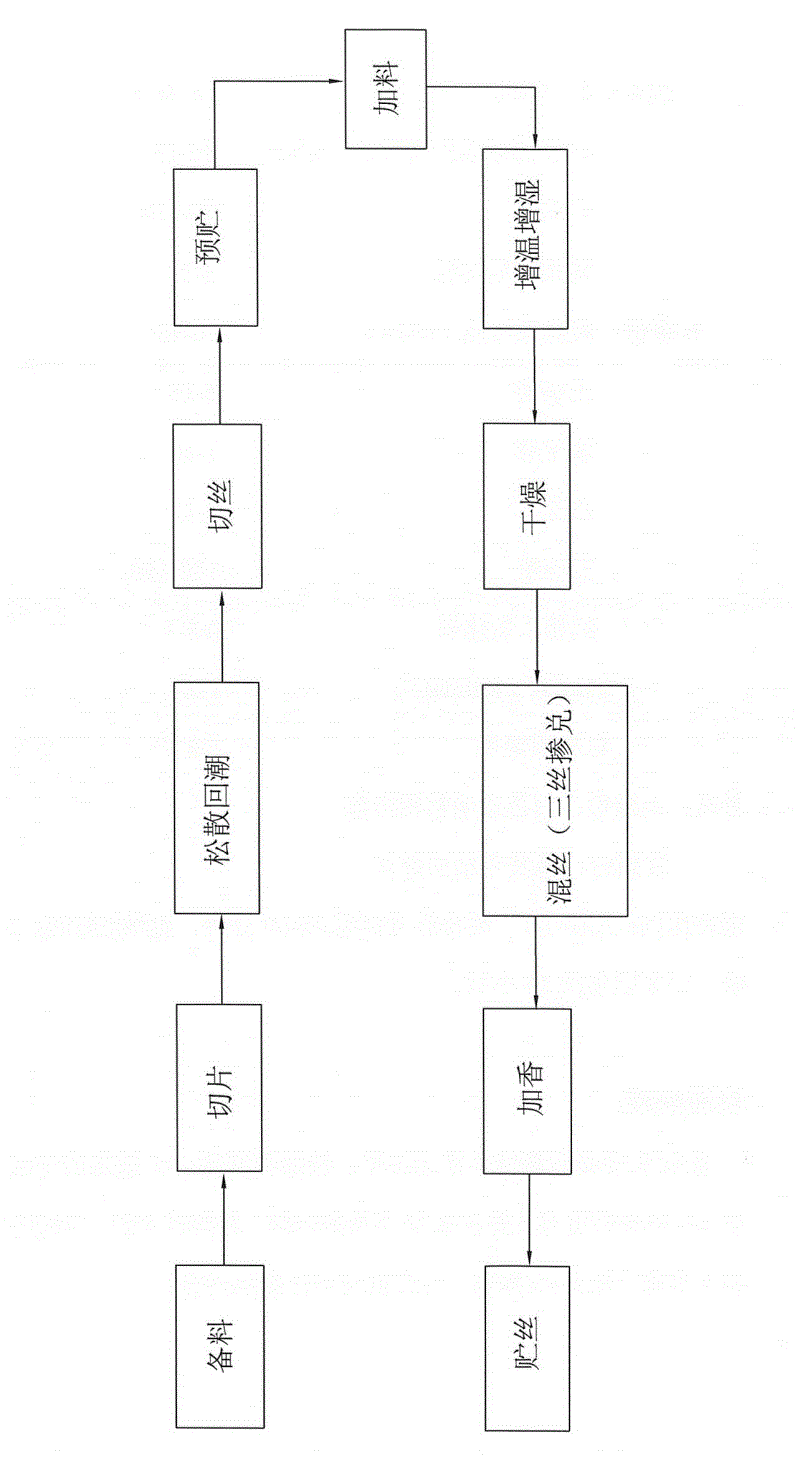

Tobacco shred processing and treating technology

A processing technology and tobacco technology, applied in the direction of tobacco, tobacco preparation, tobacco processing, etc., can solve the problems of not playing a production buffer, affecting the uniformity and precision of feeding, long process flow, etc., reducing equipment and land occupation investment, The effect of increasing absorption speed and improving physical quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0034] Flue-cured tobacco formula module 2000kg, its processing steps are:

[0035] (1) Slicing: cut the raw flue-cured tobacco block into four pieces; (2) Loosening and regaining moisture: send the cut flue-cured tobacco block to a loosening and moistening machine for increasing temperature and humidification, and controlling the moisture content of the leaves at 17%-20% , the temperature is controlled at 55°C-65°C; (3) shredded: send the loose leaves to a shredder for shredded, and the shredded width is controlled at 0.9mm; (4) pre-storage: the cut leaves The silk is sent to the storage cabinet for storage, and the storage time is greater than or equal to 1 hour, so that the moisture content of the leaf silk tends to be balanced. (5) Feeding: Send the balanced shredded leaves to a screening feeder for feeding treatment. The feeding ratio is 1-5%. The moisture content of the shredded leaves after treatment is controlled at 18%-21%, and the temperature is controlled at 45°C-55...

Embodiment 2

[0037] Flue-cured tobacco formula module 3000kg, its processing steps are:

[0038] (1) Slicing: cut the raw flue-cured tobacco block into four pieces; (2) Loosening and regaining moisture: send the cut flue-cured tobacco block to a loosening and moistening machine for increasing temperature and humidification, and controlling the moisture content of the leaves at 18%-20% , the temperature is controlled at 55°C-65°C; (3) shredded: send the loose leaves to a shredder for shredded, and the shredded width is controlled at 0.9mm; (4) pre-storage: the cut leaves The silk is sent to the storage cabinet for storage, and the storage time is greater than or equal to 1 hour, so that the moisture content of the leaf silk tends to be balanced. (5) Feeding: Send the balanced shredded leaves to the sieving feeder for feeding treatment, the feeding ratio is 1-5%, the moisture content of the shredded leaves after treatment is controlled at 19%-22%, and the temperature is controlled at 45°C-55...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com