Novel full-automatic powder producing system

A fully automatic and backup system technology, applied in the direction of dissolving, mixing machines, chemical instruments and methods, etc., can solve the problems of surrounding environmental pollution, unfavorable environmental protection, powder leakage, etc., and achieve the effect of avoiding environmental pollution and ensuring accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

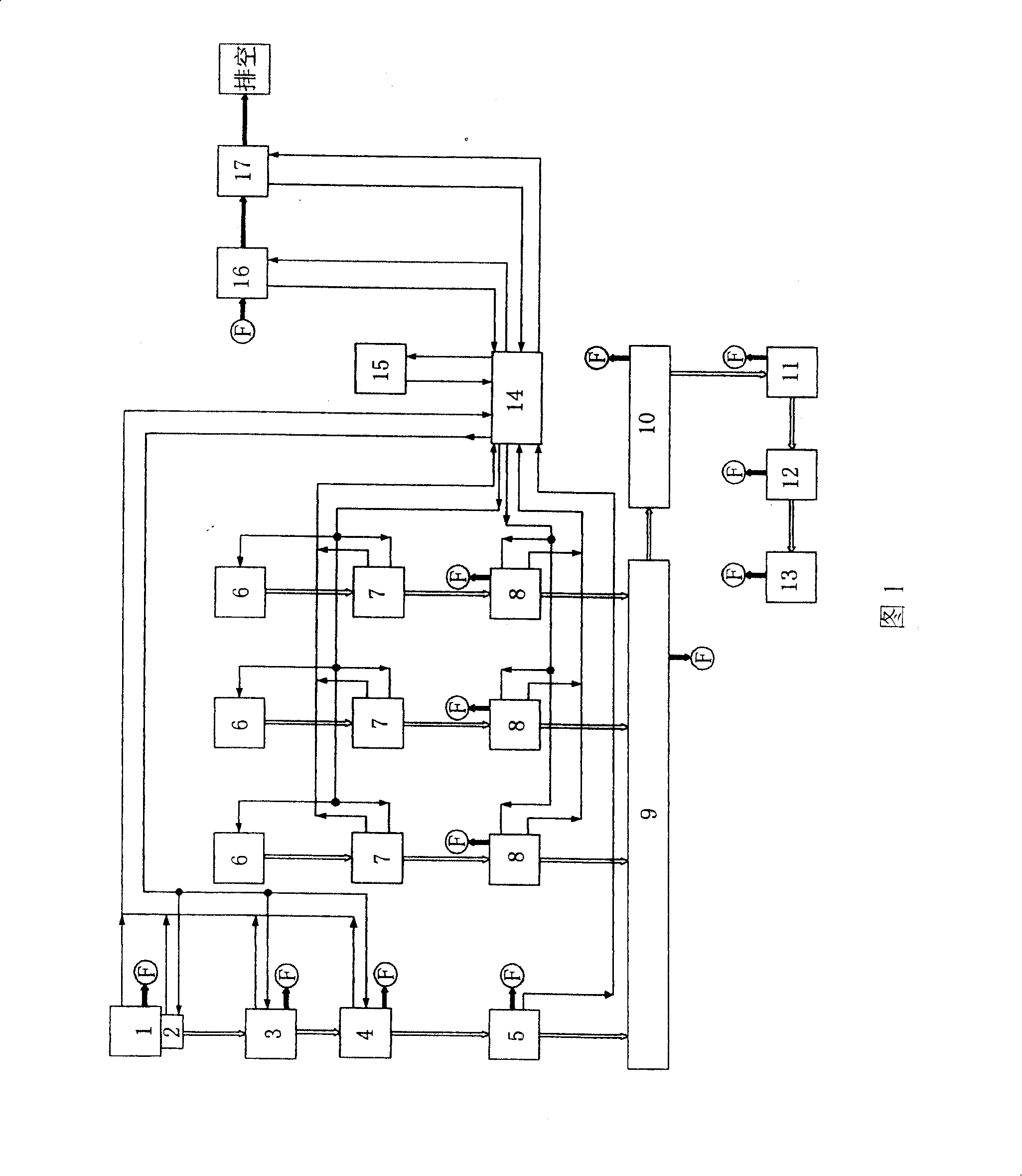

[0020] The novel fully automatic powder preparation system of the present invention will be described in detail below with reference to the accompanying drawings and examples:

[0021] As shown in Figure 1, the new automatic powder preparation system includes the main material bin 1 connected to the feeder 2, the feeder 2 connected to the screening device 3, the screening device 3 connected to the main material conveyor 4, the main material The conveyor 4 is connected with the impulse flowmeter 5, and the impulse flowmeter 5 is connected with the batching machine 9.

[0022] The auxiliary material bin 6 is connected with the decrement method weighing device 7 , the decrement method weighing device 7 is connected with the auxiliary material adding machine 8 , and the auxiliary material adding machine 8 is connected with the batching machine 9 . The batching machine 9 is connected with the mixer 10, the mixer 10 is connected with the finished product warehouse 11, the finished p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com