Acid adding machine and acid adding system

A technology of acid adding machine and acid cooling machine, which is applied to electrical components, circuits, battery pack parts, etc., can solve the problems of terminal corrosion, poor battery charging consistency, and the amount of acid and acid that cannot be added, so as to reduce damage and reduce damage. The effect of scrapping, reducing production costs and improving production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

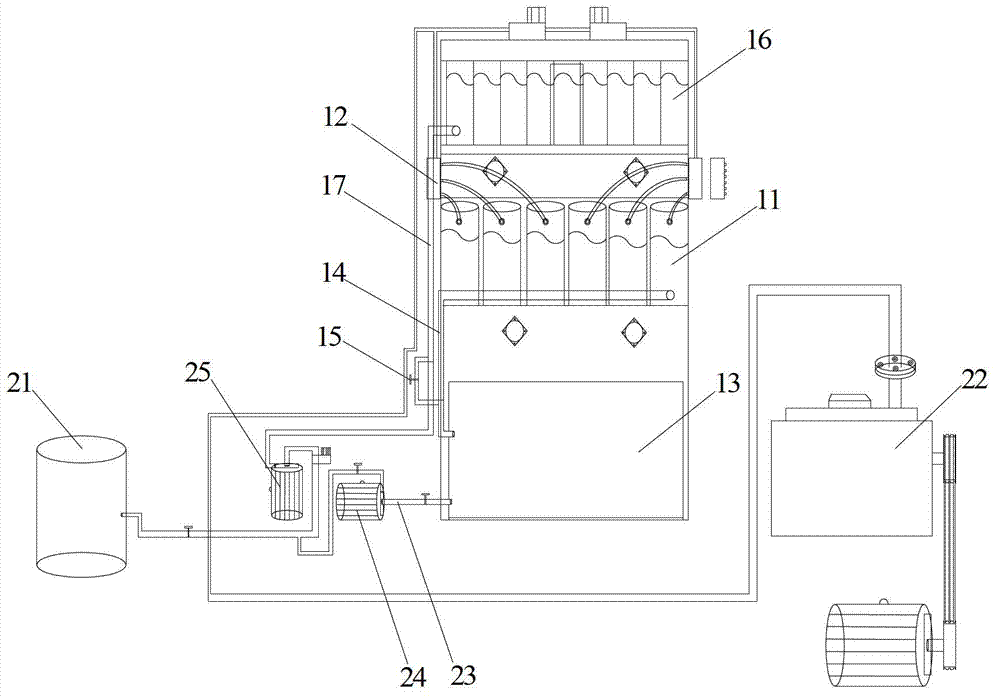

[0018] Such as figure 1 As shown, the acid adding machine of the present application, an embodiment thereof, includes an acid storage device 11 capable of metering acid liquid, a quantitative pump 12, a bottom acid tank 13 and a first conduit 14, and the quantitative pump 12 is used to draw in acid liquid , the quantitative pump 12 is connected with the acid storage device 11, and the quantitative pump 12 sends the acid liquid into the acid storage device 11 after pumping out the acid liquid. Acid unit 11 is connected. The acid storage device 11 may be one of a measuring cup, a measuring bucket or a measuring bottle.

[0019] In one embodiment, the acid adding machine of the present application also includes a top acid tank 16, the top acid tank 16 is arranged on the top of the acid storage device 11, the quantitative pump 12 connects the top acid tank 16 and the acid storage device 11, and the quantitative pump starts from the acid storage device 11. The acid liquid is extr...

Embodiment 2

[0022] Such as figure 1 As shown, the acid adding system of the present application comprises an acid adding machine, a cooling acid machine 21 and a vacuum pump 22, the vacuum pump 22 is connected with the acid adding machine, and the acid adding machine includes an acid storage device 11 capable of metering acid liquid, a quantitative pump 12, a bottom The acid tank 13 and the first conduit 14, the quantitative pump 12 is used to draw in the acid liquid, the quantitative pump 12 is connected with the acid storage device 11, and the quantitative pump 12 sends the acid liquid into the acid storage device 11, and the bottom acid tank 13 is arranged on At the lower part of the acid storage device 11 , the bottom acid tank 13 is connected to the acid storage device 11 through a first conduit 14 . The acid storage device 11 may be one of a measuring cup, a measuring bucket or a measuring bottle.

[0023] In one embodiment, the acid adding machine of the present application also i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com