Mobile tobacco charging bucket with electronic tag and operating method for charging bucket

An electronic label and moving material technology, applied in the field of tobacco processing, can solve the problems of misoperation, long cleaning time, inconvenient operation, etc., and achieve the effect of less loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] Now illustrate the present invention in conjunction with accompanying drawing and embodiment.

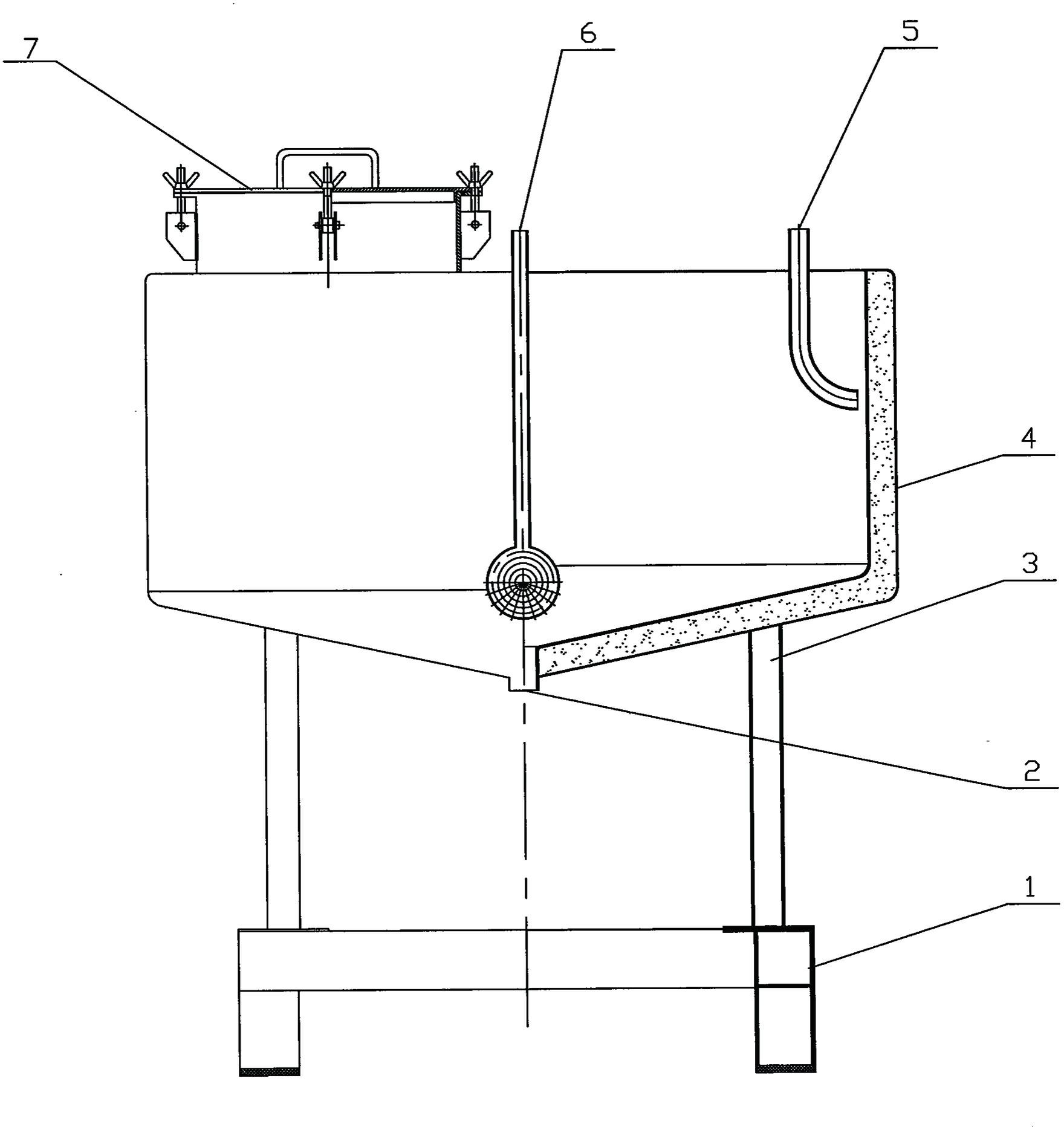

[0020] Such as figure 1 Shown is a mobile cigarette material tank with an electronic label, the mobile material tank for cigarettes is mainly composed of a tank body 4, the tank body 4 is provided with a tank cover 7 on the top, and a fixed consignment tank is connected to the bottom by tank legs 3 Chassis1. The tank body 4 is also connected with a quick connector 5 for feeding back to the feeding line of the on-site feeding machine or the flavoring machine, and a quick joint for discharging with the feeding or flavoring line of the on-site feeding machine or the flavoring machine 8. Connector 2 and a quick connector 6 that is docked with the compressed air pipeline for stirring at the scene of feeding or adding fragrance. An electronic tag is installed on the tank body 4 of the present invention, and the electronic tag is designed to be inlaid with double-layer plexiglass,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com